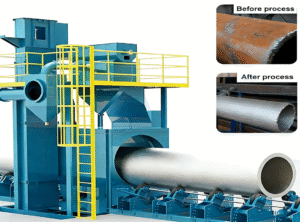

Uncontrolled casting roughness after shot blasting affects quality; scientific methods ensure stable machine shot results.

This guide details practical methods to control casting roughness during shot blasting, optimizing shot blaster operations and ensuring casting quality.

Explore key techniques and precautions for precise casting roughness control in shot blast below.

Why Is Casting Roughness Control Critical in Shot Blasting?

Controlling casting roughness during shot blasting is a core link in casting processing, directly determining the quality, performance, and subsequent processing efficiency of castings.

- Excessively high roughness after shot blast will increase the difficulty of subsequent processes such as painting, electroplating, and assembly, leading to poor adhesion of coatings, uneven stress distribution, and reduced service life of castings.

- On the contrary, excessively low roughness will reduce the bonding force between the casting surface and the coating or mating parts, affecting the overall structural stability. For different types of castings (such as automotive castings, engineering machinery castings, and precision castings), the required roughness range varies significantly—precise control ensures that castings meet design standards.

Additionally, stable casting roughness reduces rework rates, lowers production costs, and improves the competitiveness of products. In shot blasting operations, the shot blaster’s performance, machine shot parameters, and abrasive selection all affect casting roughness, so mastering scientific control methods is essential for high-quality shot blasting.

How to Select Suitable Abrasives to Control Casting Roughness?

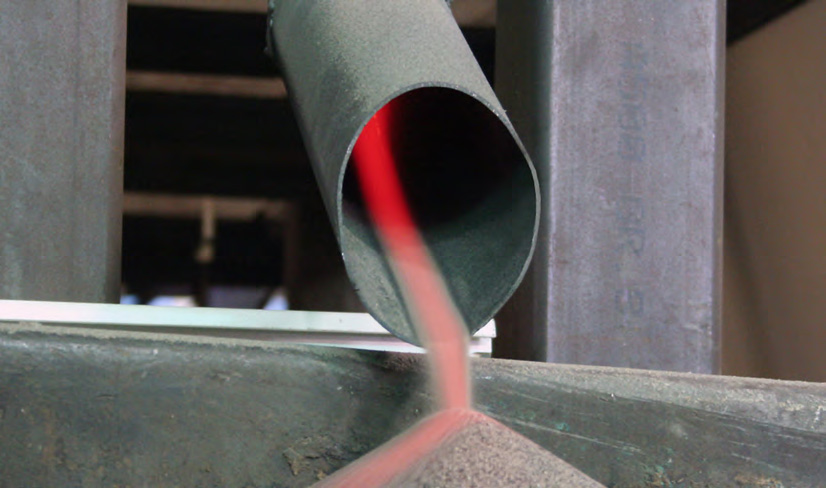

Abrasive selection is the foundation of casting roughness control during shot blasting, as the type, particle size, and hardness of abrasives directly affect the impact effect of machine shot on castings.

- Choose the right abrasive type: for castings that require moderate roughness (Ra 1.6-6.3μm), spherical steel shot is preferred, as it has a smooth surface and uniform impact force, resulting in a consistent casting surface. For castings that need slightly higher roughness (Ra 6.3-12.5μm), angular steel grit can be used, as its sharp edges can create deeper surface textures. Avoid using mixed abrasives with inconsistent shapes, as they will cause uneven roughness.

- Control abrasive particle size precisely: the larger the abrasive particle size, the higher the casting roughness; the smaller the particle size, the lower the roughness. According to the required roughness, select abrasives with a particle size range of 0.5-2.0mm, and use a multi-layer sieve to filter out impurities and irregular particles before adding them to the shot blaster.

- Match abrasive hardness with casting material: abrasive hardness should be 10-20% higher than the casting’s hardness—overly hard abrasives will cause excessive roughness, while overly soft abrasives will fail to meet cleaning and roughness requirements. Proper abrasive selection can lay a solid foundation for precise roughness control in shot blast.

How to Adjust Shot Blaster Parameters to Control Casting Roughness?

Adjusting shot blaster parameters is the most direct and effective method to control casting roughness during shot blasting, as parameters such as machine shot speed, flow rate, and distance determine the impact intensity on castings.

- Control the projectile speed: the higher the projectile speed, the greater the impact force, and the higher the casting roughness. Install a variable frequency drive (VFD) on the shot blaster to adjust the impeller speed steplessly—for castings requiring low roughness, set the speed to 1200-1500rpm; for moderate roughness, set it to 1500-1800rpm; for high roughness, set it to 1800-2000rpm. Regularly calibrate the speed to ensure stability.

- Optimize the abrasive flow rate: excessive flow rate will cause overlapping impact on the casting surface, increasing roughness; insufficient flow rate will lead to uneven roughness. Adjust the flow rate to 70-80% of the shot blaster’s rated capacity, and use a flow meter to monitor in real time, ensuring uniform feeding.

- Control the shot blast distance and angle: the distance between the shot blaster’s nozzle and the casting should be 50-100mm—too close will increase roughness, too far will reduce impact effect. Maintain a 45-60° impact angle to ensure uniform surface treatment. Adjusting these parameters reasonably can achieve precise control of casting roughness.

How to Optimize Shot Blasting Operation Process for Roughness Control?

Optimizing the shot blasting operation process is crucial to ensuring consistent casting roughness, avoiding quality fluctuations caused by improper operation.

- Pre-treat castings before shot blast: remove oil, rust, and loose sand on the casting surface, as these impurities will affect the impact effect of machine shot and lead to uneven roughness. Use cleaning agents or high-pressure air to clean castings, ensuring a clean surface before shot blasting.

- Arrange castings reasonably: place castings in the shot blaster evenly, avoiding overlapping or shielding, ensuring that all surfaces are fully exposed to shot blast. For complex-shaped castings, adjust the placement angle or use a rotating fixture to ensure uniform impact.

- Control shot blasting time: the longer the shot blasting time, the higher the roughness—set the time according to the required roughness and casting material. For example, cast iron castings require 30-60 seconds, while steel castings require 60-90 seconds. Avoid over-blasting or under-blasting.

- Conduct post-shot blast inspection: use a roughness tester to detect the casting surface after shot blasting, record the data, and adjust shot blaster parameters or operation methods in time if the roughness exceeds the standard. Optimizing the operation process can reduce roughness fluctuations and ensure stable quality.

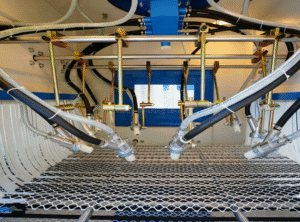

How to Maintain Shot Blaster to Ensure Stable Roughness Control?

Regular maintenance of the shot blaster is essential to maintain its performance, ensuring stable casting roughness control during long-term shot blasting operations.

- Establish a daily maintenance routine: after each shot blast operation, clean the shot blaster’s impeller, nozzle, pipeline, and hopper to remove residual abrasives and debris, which may cause uneven abrasive flow and affect roughness. Inspect the nozzle for wear—worn nozzles will change the shot blast direction and intensity, leading to uneven roughness. Replace worn nozzles in time.

- Conduct weekly maintenance: lubricate the shot blaster’s motor, bearings, and other moving parts to ensure smooth operation. Check the impeller blades and shot wheel for wear, and replace them if necessary, as uneven wear will cause unstable projectile speed.

- Perform monthly maintenance: calibrate the shot blaster’s speed, flow rate, and pressure gauges to ensure accurate parameters. Inspect the abrasive recovery system to ensure normal operation, avoiding abrasive waste and uneven feeding.

Additionally, train operators to master the correct operation and maintenance skills, enabling them to identify early signs of equipment abnormalities and take timely measures. Proper maintenance ensures that the shot blaster operates stably, providing a guarantee for precise casting roughness control.

Conclusion

Abrasive selection, parameter adjustment and maintenance ensure precise casting shot blasting roughness control.

For professional guidance on casting shot blasting roughness control and shot blaster optimization,

contact us via email: [email protected]