- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

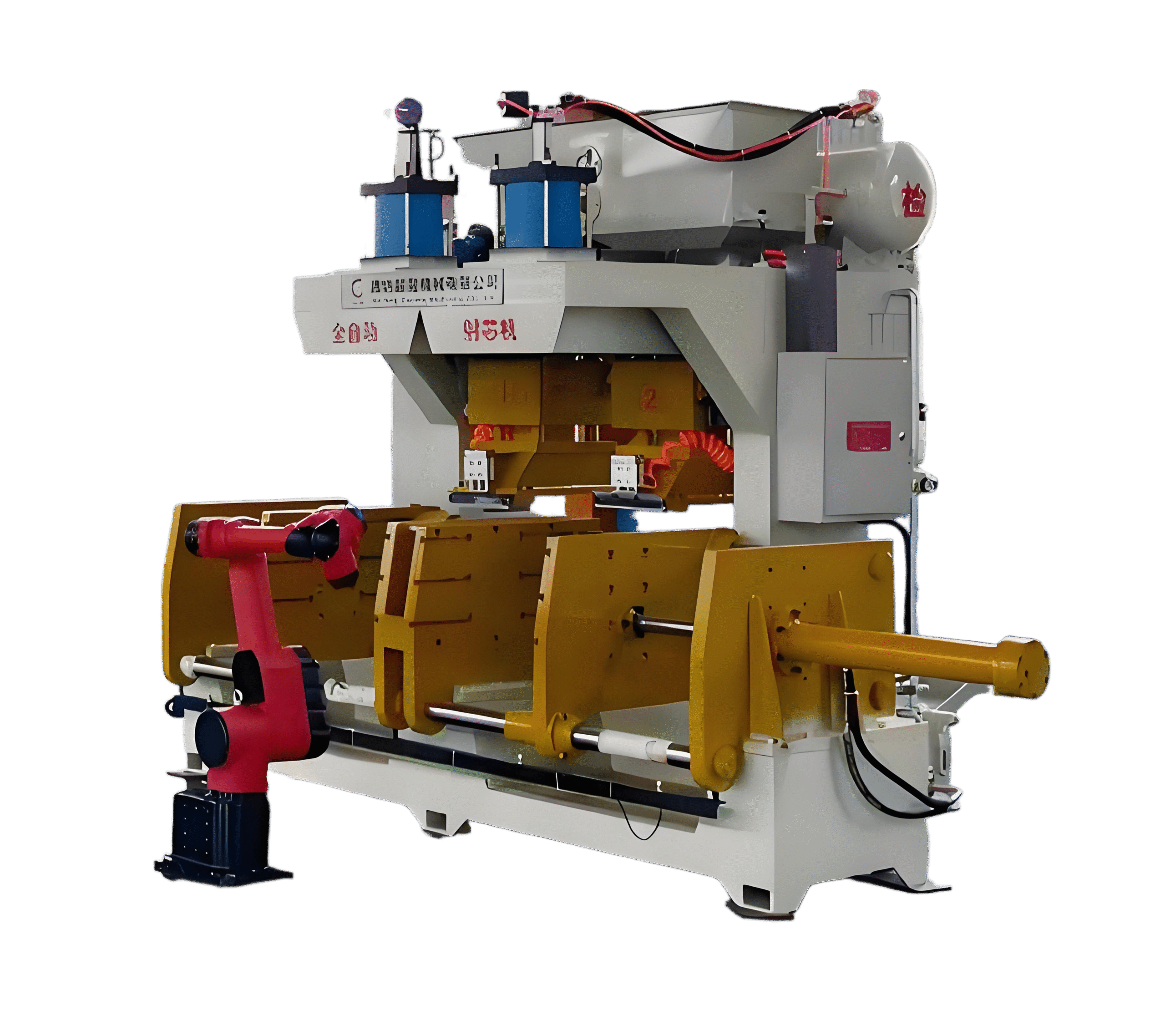

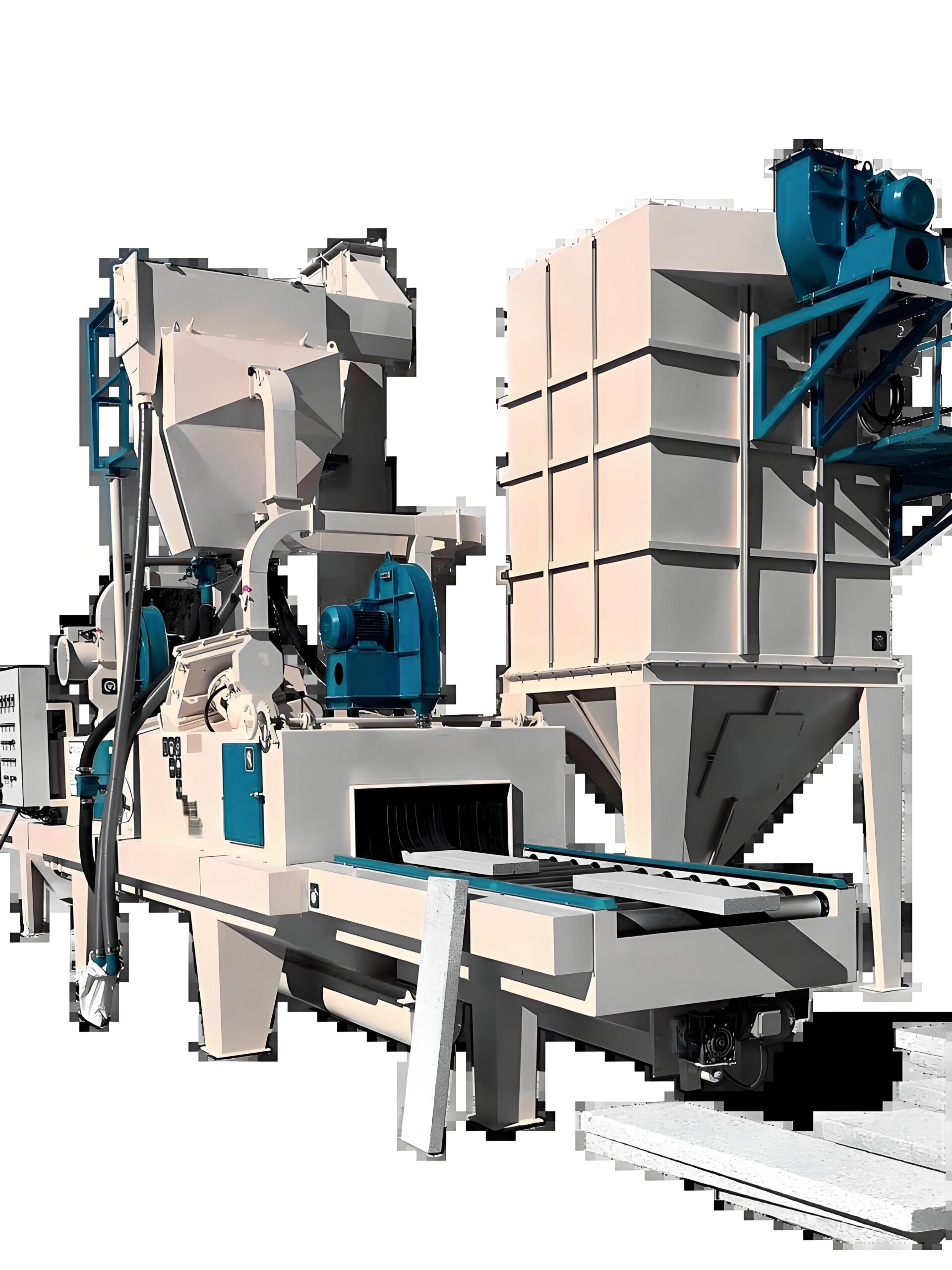

Rotary table shot blasting machine

Rotary table shot blasting machine

- Integral or stand alone cartridge type dust collectors

- Manganese and hi-alloy wear resistant cabinet liners;

- Fully enclosed tables with single or double work door

- Stationary rotary table to keep abrasive inside machine

- Work door opening exposes table for loading with overhead crane or fork lift

- Optional overhead monorail slot for simplified loading of large parts

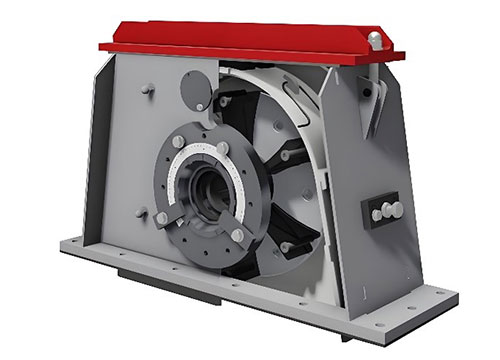

- Wheel options: Direct drive or belt drive

Product Parameters

Applications

Rotary table shot blasting machine is made to shot blast various part shapes and dimensions, castings and forging parts, pressed parts, steel and non-ferrous metal parts and parts made from fragile materials. It is used for surface cleaning, casting sand removing, and surface roughing before coating process.

Normally, this shot blasting machine has two big doors which is easy for loading and unloading. Workpieces are loaded on a rotating table. The machine has one or two blasting wheels on the top or sometimes one on the top, another one on the side. The blasting chamber is protected with manganese steel liner.

Non-standard rotary table blasting machine is designed to have 6, 8, 10 blast wheels. The machine is used for blasting huge castings or steel structures.

Rotary table diameter is from 1000mm to 4000mm. Workpiece weight ranges from 10kgs to 50,000kgs.

Main Benefits

- Integral or stand alone cartridge type dust collectors

- Manganese and hi-alloy wear resistant cabinet liners;

- Fully enclosed tables with single or double work door

- Stationary rotary table to keep abrasive inside machine

- Work door opening exposes table for loading with overhead crane or fork lift

- Optional overhead monorail slot for simplified loading of large parts

- Wheel options: Direct drive or belt drive

Model & Specification

| ITEM | RT1200 | RT1500 | RT2500 |

| Maximum dimension of chamber (mm) | Φ1350×560 | Φ1750×860 | Φ2750×560 |

| Maximum workpiece weight (kg) | 300 | 500 | 1000 |

| Diameter of Turn Table(mm) | Φ1200 | Φ1500 | Φ2500 |

| Number of blast wheels and power (kw) | 11 | 2×11 | 2×15 |

| Overall dimension (mm) | 1500×3450×3780 | 1900×3450×4160 | 4260×3647×5366 |

| Material of table | Manganese | Manganese | Manganese |

| Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

| Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

- Manganese table

- High wearable, long life time

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement