- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

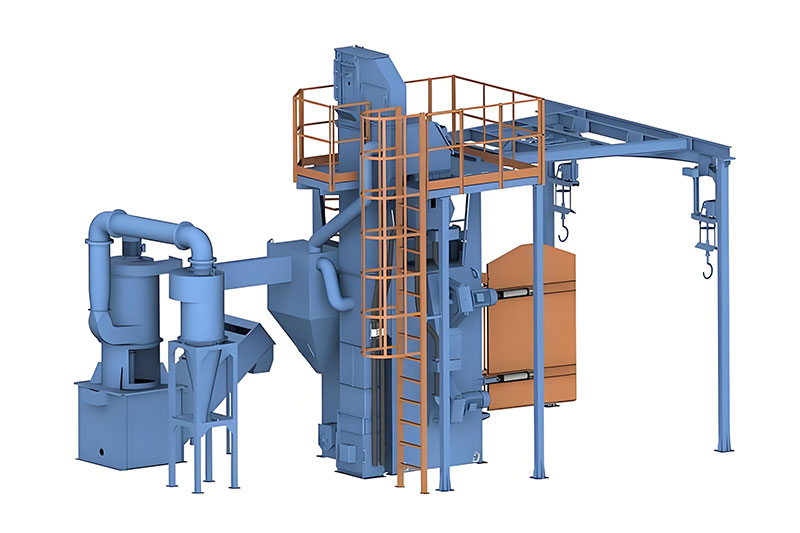

Overhead Y track type shot blasting machine

Overhead Y track type shot blasting machine

- The spinner hanger type shot blasting machine is very versatile unit, and its compact design requires minimum floor space.

- Hanger-type blast machines are offered either for batch or continuous processing connected to following coating and drying.

- Hanger type blasting is the best blast cleaning method for many work pieces that can’t be tumbled.

- Touch screen operator interface and integrated PLC optional;

- The blasting chamber is protected by wear-resistant manganese steel liner.

- A zigzag nylon brush and polyurethane strop sealing device on top of the chamber ensures no emission of abrasive and dust flying out from the blasting chamber.

Quote Now

Product Parameters

Applications

Spinner hanger blast machines are flexible types of blasting equipment. They are used to remove rust, scale, sand and burrs from many kinds of work pieces, which is fragile and sensitive parts that cannot be tumbled in bulk loads.

Hanger type blasting machines are also used for the finish blasting of sensitive work pieces or to roughen work piece surfaces for subsequent coating.

Work pieces weight can be from 1kg to 10,000 kg. Work pieces can be small, simple castings, weldments, or complex, heavy and large parts.

Main Benefits

- The spinner hanger type shot blasting machine is very versatile unit, and its compact design requires minimum floor space.

- Hanger-type blast machines are offered either for batch or continuous processing connected to following coating and drying.

- Hanger type blasting is the best blast cleaning method for many work pieces that can’t be tumbled.

- Touch screen operator interface and integrated PLC optional;

- The blasting chamber is protected by wear-resistant manganese steel liner.

- A zigzag nylon brush and polyurethane strop sealing device on top of the chamber ensures no emission of abrasive and dust flying out from the blasting chamber.

Model & Specification

| MODEL AND SPECIFICATION OF HANGER TYPE SHOT BLASTING MACHINE | |||||

| ITEM / MODEL | QD376 | QD378 | QD3710 | QD3720 | QD3730 |

| Workpiece diameter | 700mm | 1000mm | 1200mm | 1400mm | 1800mm |

| Workpiece height | 1000mm | 1500mm | 1800mm | 2200mm | 2300mm |

| Turbine quanity | 2 | 2 | 2 | 3 | 3/4 |

| Turbine motor power | 7.5 kw | 7.5 kw/ 11kw | 11/15kw | 11kw/15kw | 15/kw |

| Cleaning time | 5-10 minutes | 5-10 minutes | 5-10 minutes | 10-15 mintes | 10-15 minutes |

| Foundation | no pit | no pit | no pit | need pit | need pit |

| Total power | about 22 kw | about 35 kw | about 47 kw | about 67 kw | about 74 kw |

| Abrasive used | S280, S330 | S280, S330 | S280, S330 | S330,S390 | S330,S390 |

| Dust collector | Baghouse type | Baghouse type | Baghouse type | Baghouse type | Baghouse type |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

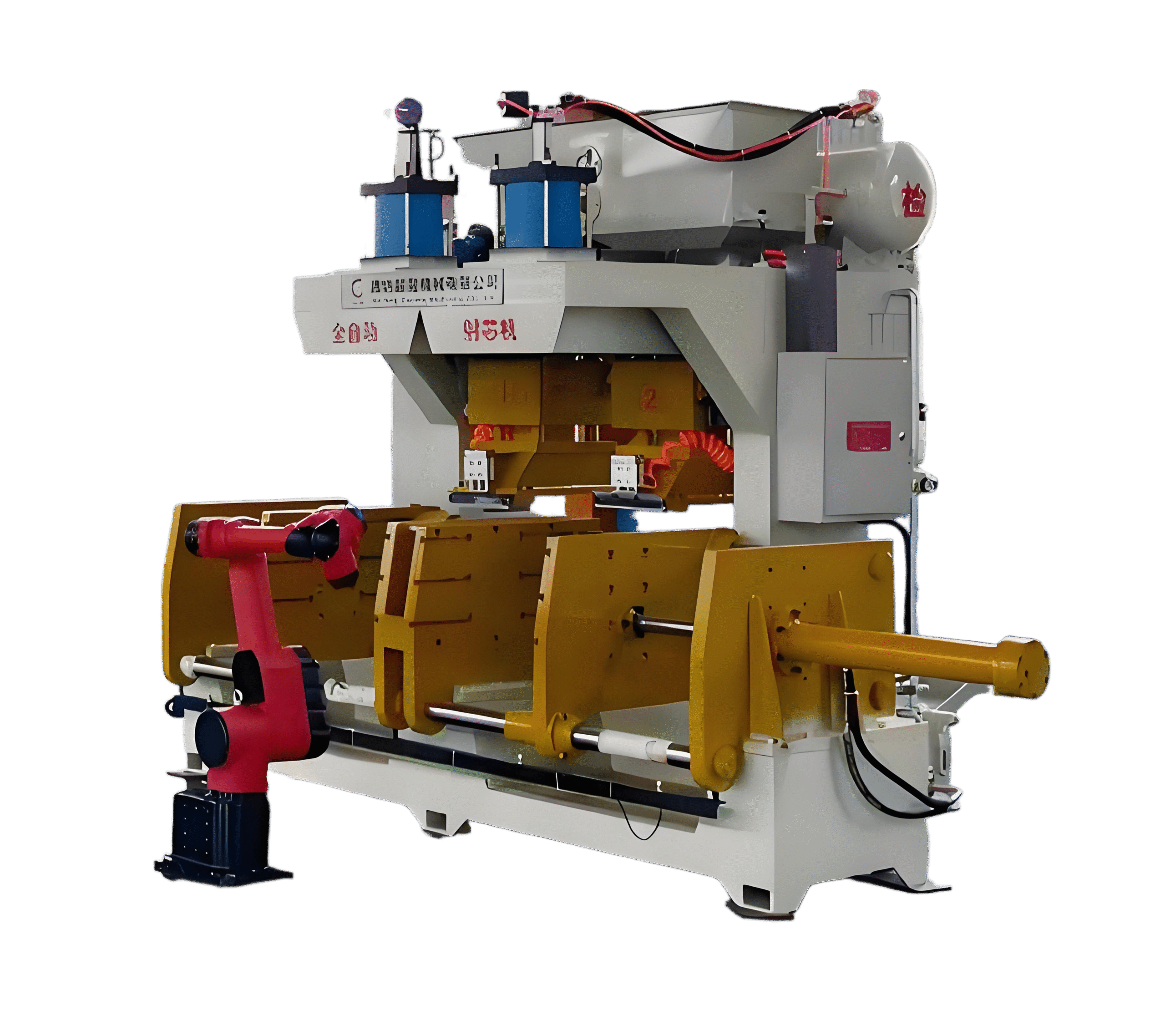

Specially designed rotation mechanism

- Manganese steel made gear

- Chain rotation device

- Special sealing mechanism for rotation area

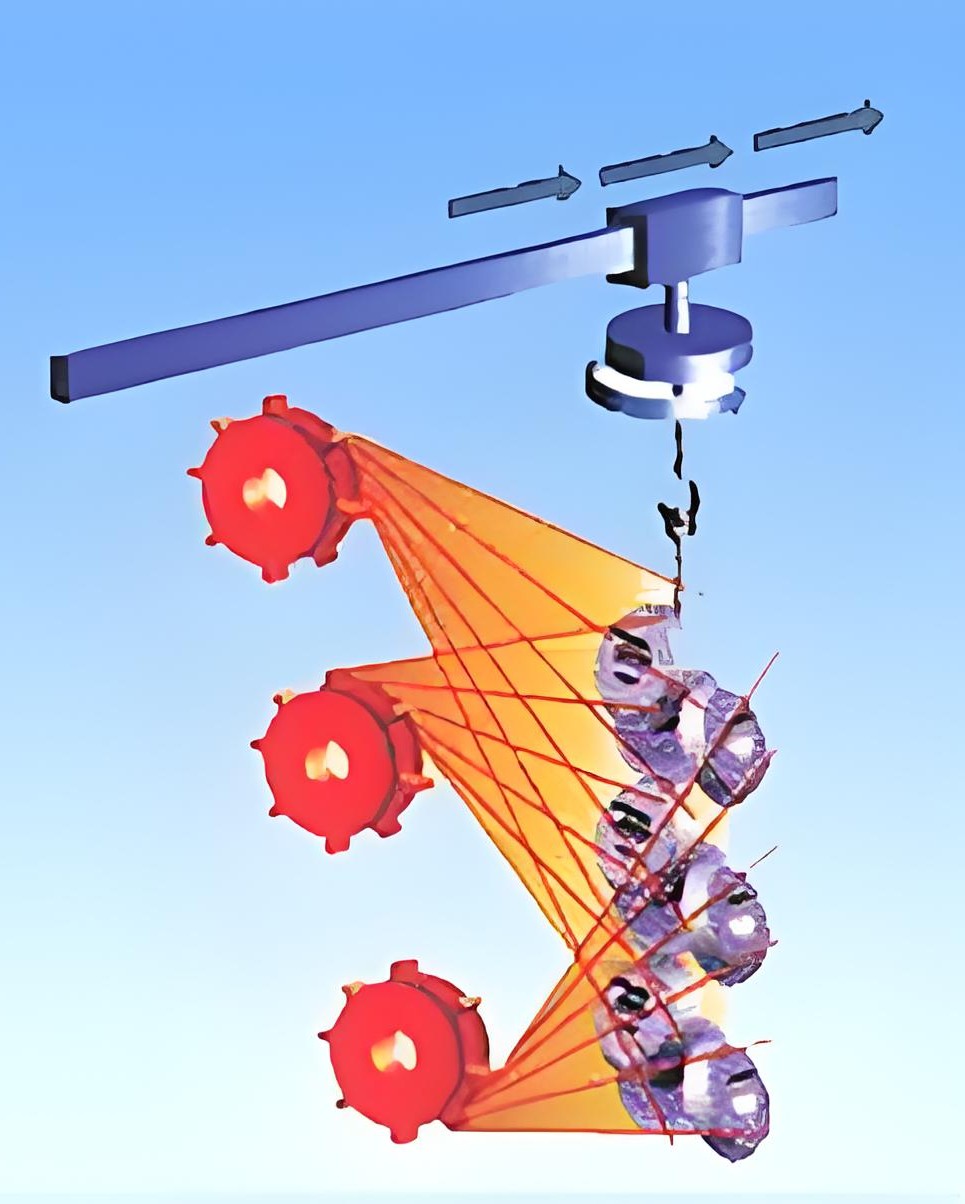

3D simulation

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

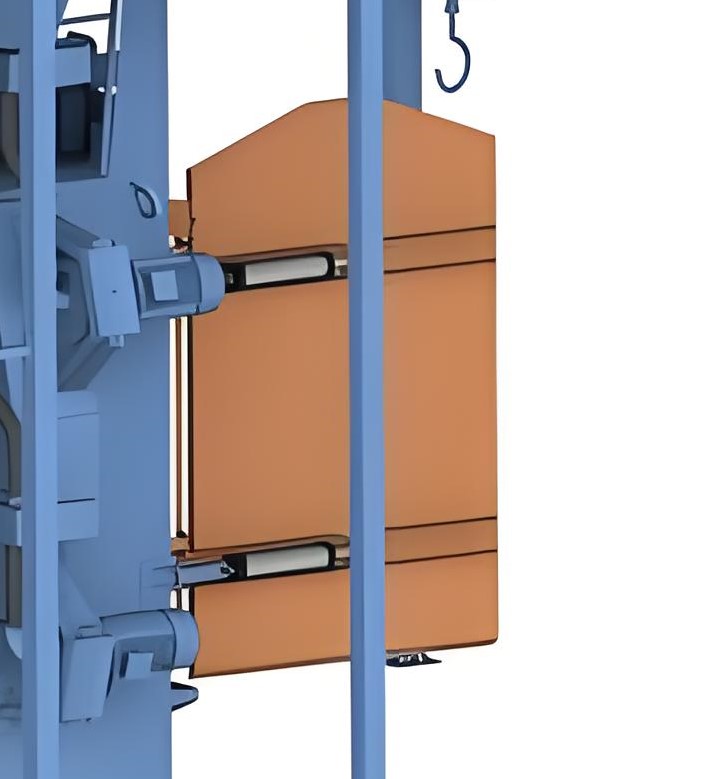

Shot Blasting Cabinet

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement

Pneumatic open gate

- AirTac air cylinder

- Automatic open