- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

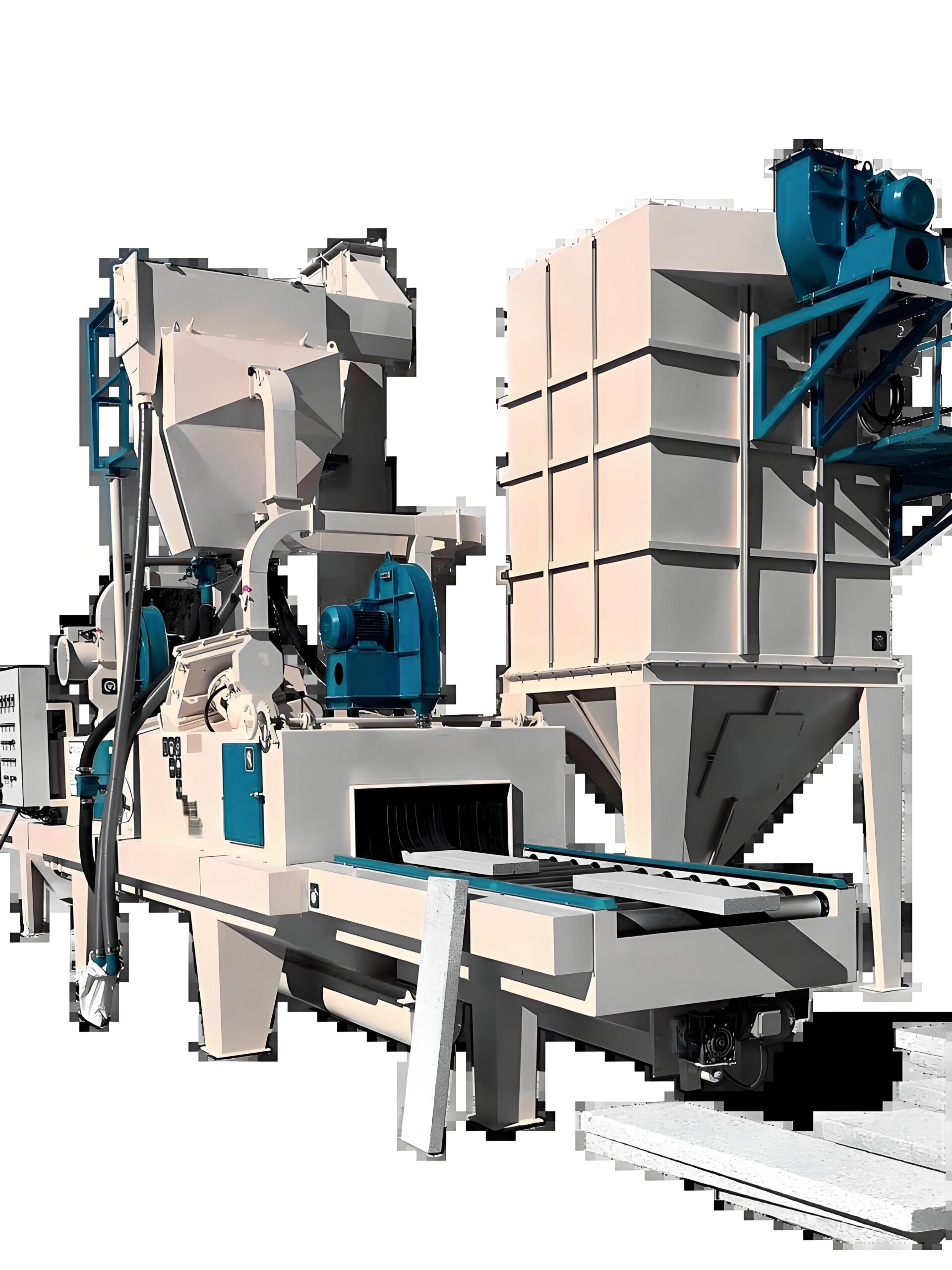

Wire mesh belt shot blasting machine

Wire mesh belt shot blasting machine

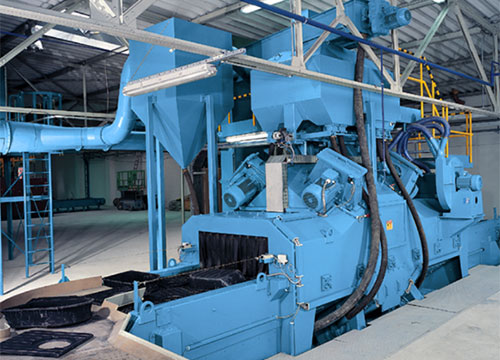

- The wire mesh belt shot blasting machine is compact design and it doesn’t need a pit.

- Use highly wear-resistant wire mesh belt, which has long life time.

- Wire mesh conveyor speed adjustable from 0.5m/min to 2m/min.

- Touch screen operator interface and integrated PLC, automatic mode or manual mode;

- The blasting chamber is protected by wear-resistant manganese steel liner, lifetime is about 15000 hours.

- Series of rubber screens keep the abrasive inside the blasting machine.

- Continuous flow makes this machine can connect with the production line.

Quote Now

Product Parameters

Applications

Wire mesh belt shot blasting machine is suitable for continuous blasting thin and collision-sensitive die castings, pressure castings, ferrous and non-ferrous castings, forgings, automotive accessories, and weldments. Workpiece weight ranging from 1kg to 100kg.

A highly wear-resistant wire mesh belt, with tension adjustment, provides the part transport. Wire mesh belt width has 600mm, 800mm, 1000mm and 1200mm.

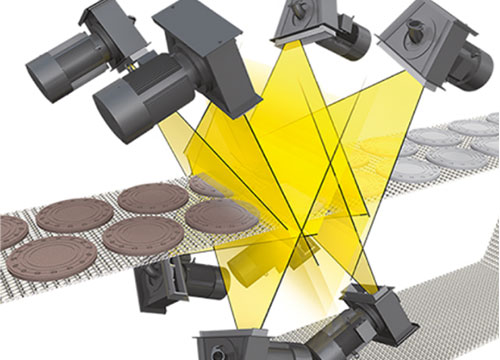

Due to the wire mesh belt, the workpieces can be blasted both from upper and bottom. Normally the machine has 4 blast wheel, 6 blast wheels or 8 blast wheels.

Main Benefits

- The wire mesh belt shot blasting machine is compact design and it doesn’t need a pit.

- Use highly wear-resistant wire mesh belt, which has long life time.

- Wire mesh conveyor speed adjustable from 5m/min to 2m/min.

- Touch screen operator interface and integrated PLC, automatic mode or manual mode;

- The blasting chamber is protected by wear-resistant manganese steel liner, lifetime is about 15000 hours.

- Series of rubber screens keep the abrasive inside the blasting machine.

- Continuous flow makes this machine can connect with the production line.

Model & Specification

| Machine type | QW600 | QW800 | QW1000 | QW1000-X | QW1250 | QW1250-X |

| Machine Opening dimensions ø x b (mm) | 600×400 | 800×500 | 1000×500 | 1000×500 | 1250×600 | 1250×600 |

| Number of wheels | 4 | 4 | 4 | 8 | 4 | 8 |

| Wheel motor power (kW) | 7.5 | 11 | 15 | 11 | 15 | 11 |

| Total installed power (kW) | 37 | 53 | 71 | 101 | 73 | 103 |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

Manganese wire mesh belt

- Manganese wire mesh belt

- High wearable, long life time

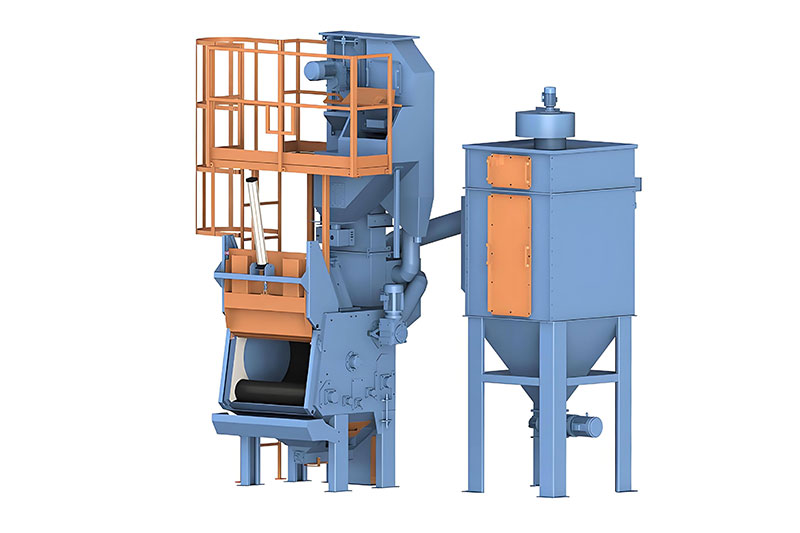

3D simulation

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

Shot Blasting Cabinet

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement

In-line production

- Connect with other equipment,

- Continuous work process for in-line production