- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

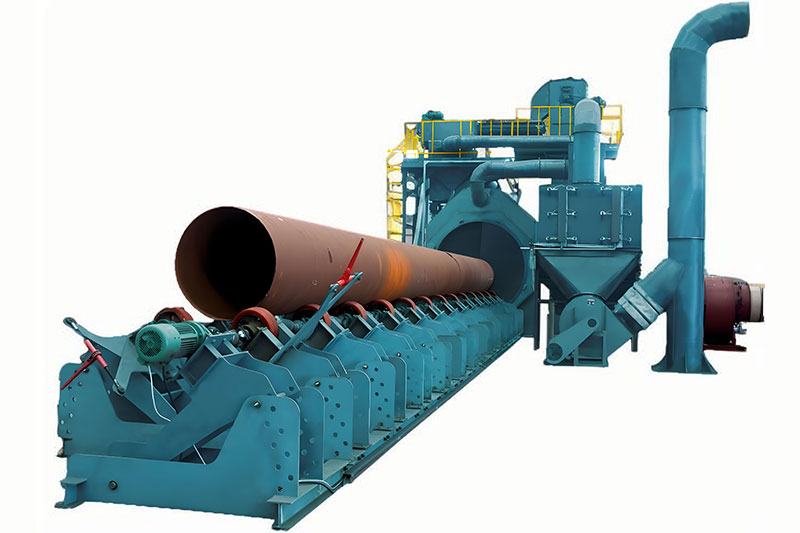

Pipe Internal Blasting Machine

Pipe Internal Blasting Machine

- Proper mill profile is achieved to give the best adherence of pipe coating

- Fully tailor made blasting machine according to pipe diameter;

- Fully automated pipe machines remove rust and scale prior to coating

- Touch screen operator interface and integrated PLC, automatic mode or manual mode;

- Heavy duty construction built to last

Quote Now

Product Parameters

Applications

The steel pipe shot blasting machine is a blasting machine with blast wheel, designed for removing scale, paint and rust from carbon steel pipes internal wall. It is widely used in oil, gas, offshore and chemical industry.

Main Benefits

- Proper mill profile is achieved to give the best adherence of pipe coating

- Fully tailor made blasting machine according to pipe diameter;

- Fully automated pipe machines remove rust and scale prior to coating

- Touch screen operator interface and integrated PLC, automatic mode or manual mode;

- Heavy duty construction built to last

Model & Specification

| Machine type | QGN-700 | QGN-1200 | QP-2000 |

| Max diameter of pipe (mm) | 700 | 1200 | 2000 |

| Max speed (m/min) | 1 | 0.8 | 0.5 |

| Type of transport | V rollers | V rollers | V rollers |

| Blast wheel power | 11kw | 18.5kw | 22kw |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

V shape roller

- Durable material;

- Easy for pipe movement and rotation;

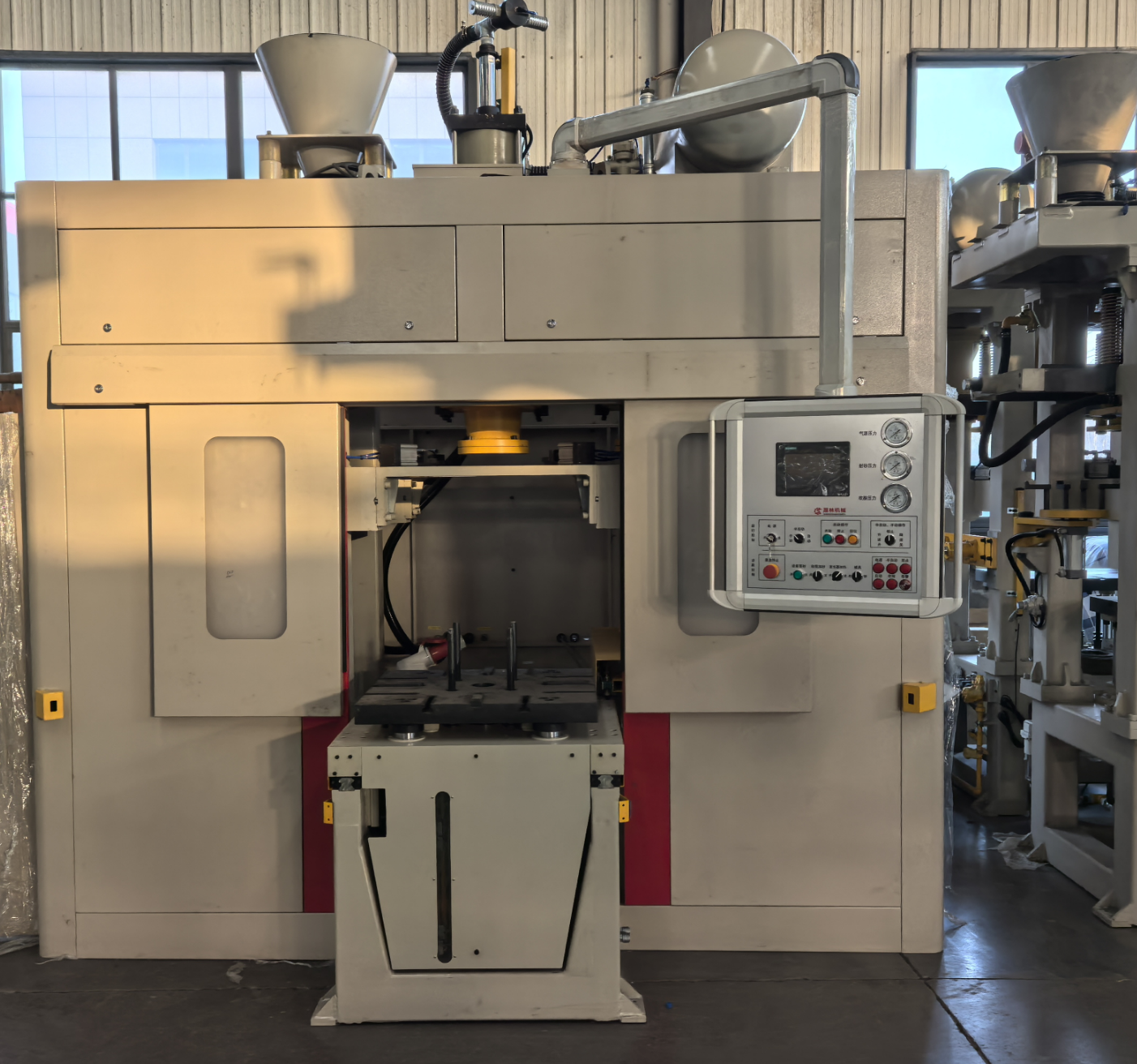

Special blast wheel

- Big power motor;

- Eco motor optional

- High speed abrasive throw

- High chrome wear resistant parts

Abrasive recovery

- High resistant rubber belt

- No need high power hydraulic station