- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

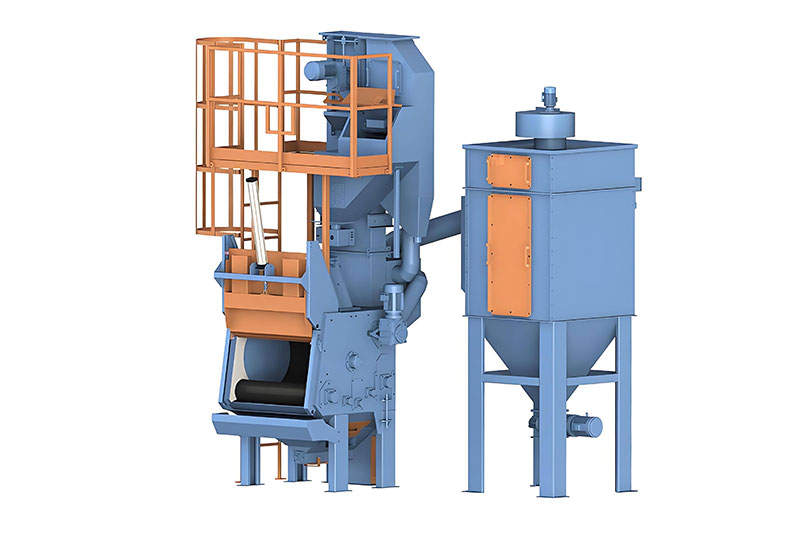

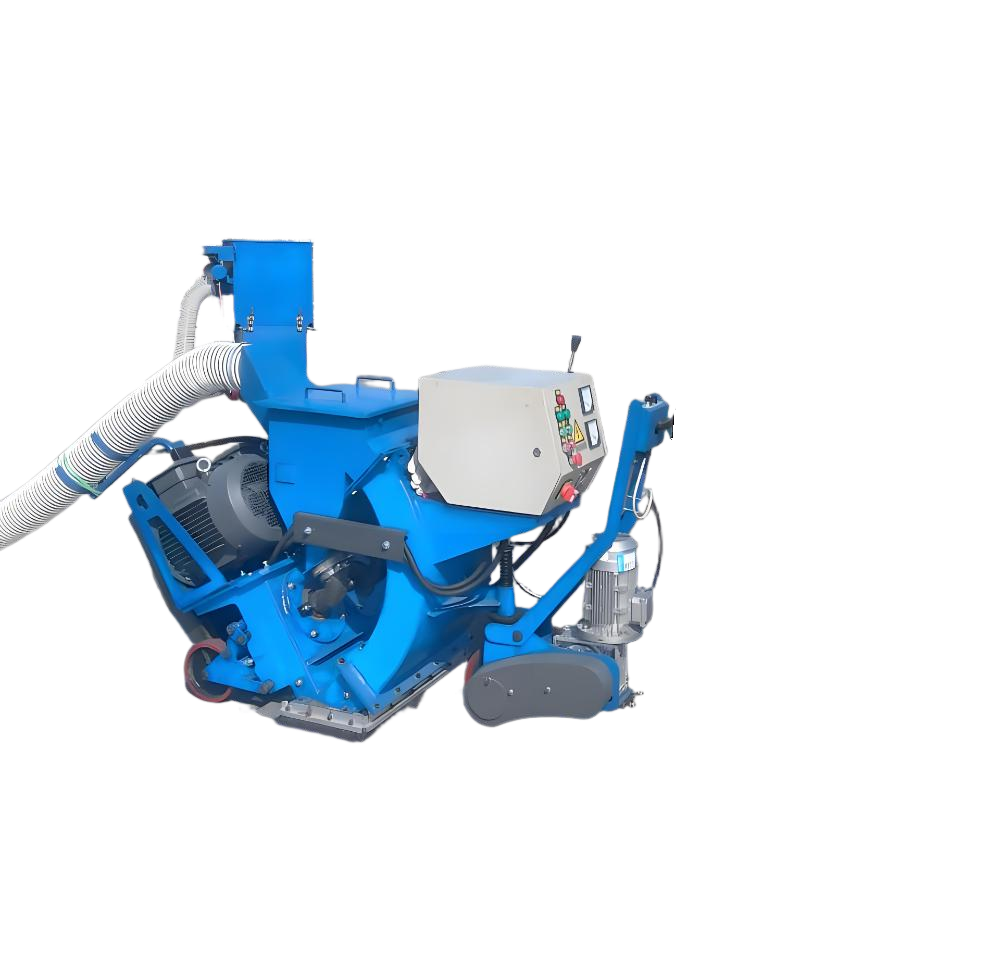

Rubber belt tumble shot blasting machine

Rubber belt tumble shot blasting machine

- Automatic door optional;

- Extremely compact design, minimum floor space required;

- Cabinet liner options utilizing cast manganese alloy materials;

- Touch screen operator interface and integrated PLC optional;

- High efficiency bag type dust collectors;

- Two steps air wash separator;

- Semi-automatic or fully automatic loader optional;

- Direct drive, spindle drive or variable speed abrasive wheels

- Commercially available parts and components

- Cast manganese steel belt available on steel belt versions;

- Modular design allows for simple assembly of the equipment on site.

Product Parameters

Applications

Tumble blast machine with rubber belt is ideal for mass-produced parts, which can be tumbled and will perfectly meet your requirements for batch cleaning, decoring, descaling, deflashing, deburring, and shot peening parts. They are mostly used for process ferrous and non-ferrous castings, forgings and heat treated parts.

The use of a rubber belt conveyor ensures a relatively gentle tumbling motion. Because clearances are kept small, it is also possible to blast extremely tiny work pieces.

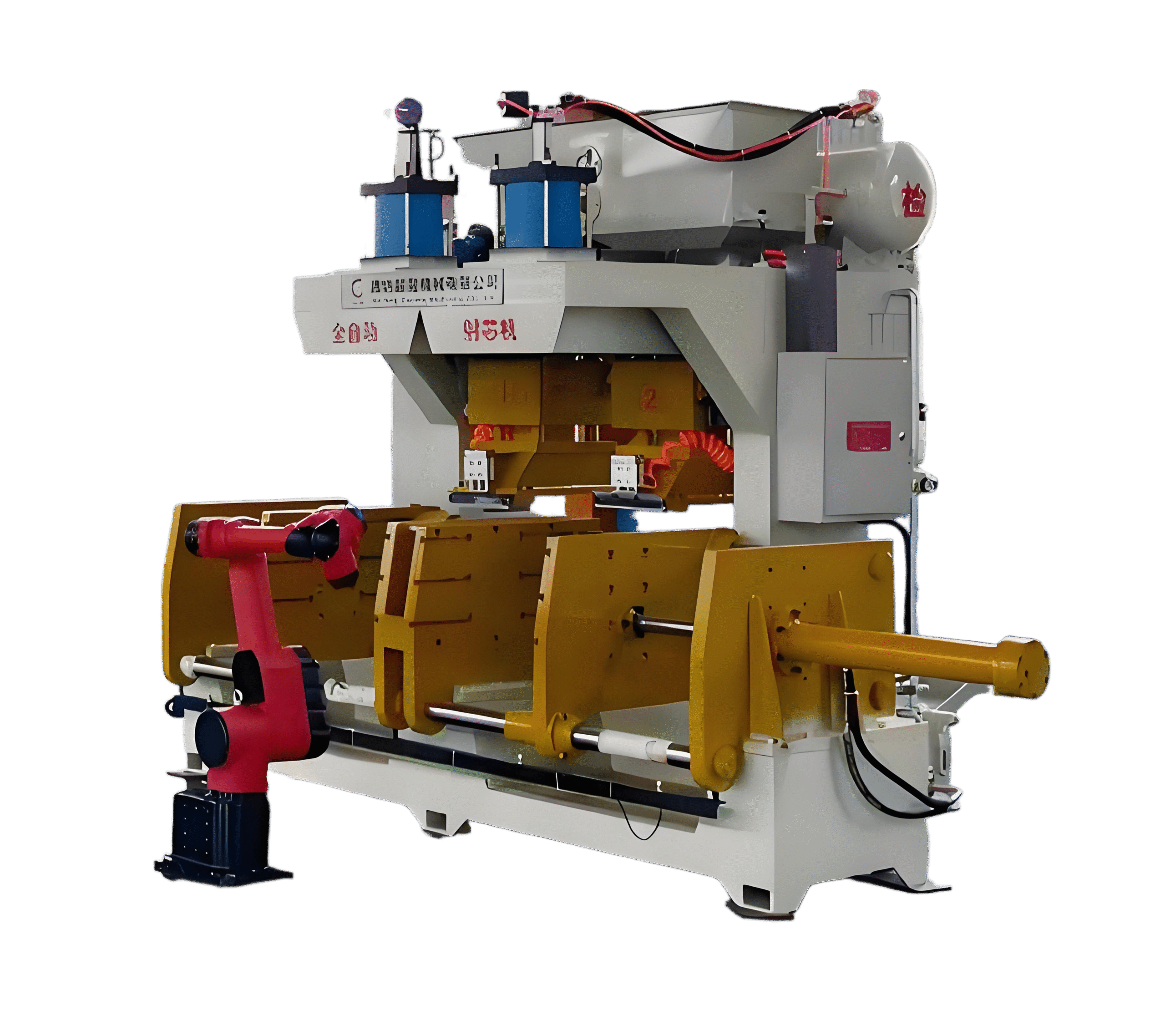

Shot blasting machine type Q32 series can be integrated to a fully automatic process with addition of loading and unloading equipment. Tumble blast machines are built in size that can accept single fill / load from 200kg up to 1,350 kg.

Main Benefits

- Automatic door optional;

- Extremely compact design, minimum floor space required;

- Cabinet liner options utilizing cast manganese alloy materials;

- Touch screen operator interface and integrated PLC optional;

- High efficiency bag type dust collectors;

- Two steps air wash separator;

- Semi-automatic or fully automatic loader optional;

- Direct drive, spindle drive or variable speed abrasive wheels

- Commercially available parts and components

- Cast manganese steel belt available on steel belt versions;

- Modular design allows for simple assembly of the equipment on site.

Model & Specification

| Item | Units | Q326 | QR3210 | Q3220 |

| Productivity | T/h | 0.6-1.2 | 1.5-2.5 | 4.0-5.0 |

| Feeding amount | kg | 200 | 600 | 1200 |

| Maximum weight of single piece | kg | 10 | 30 | 40 |

| Diameter of end disk | mm | Ø650 | Ø1000 | Ø1000 |

| Effective volume | M3 | 0.15 | 0.3 | 0.6 |

| Shot-blasting capacity | Kg/min | 100 | 250 | 250×2 |

| Air volume for dedusting | M3/h | 2200 | 5000 | 6000 |

| Power consumption | kw | 12.6 | 24.3 | 51 |

| Outline dimention | mm | 3681*1650*5800 | 3972*2600*4768 | 7200*3500*5800 |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

- Standard manual open door;

- Automatic open door optional;

- Standard machine need to load by hand;

- Optional automatic loader available;

- Durable rubber belt conveyor;

- With ribs for easy tumbling, or without;

- Workpieces unloading by belt conveyor or vibration conveyor