- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

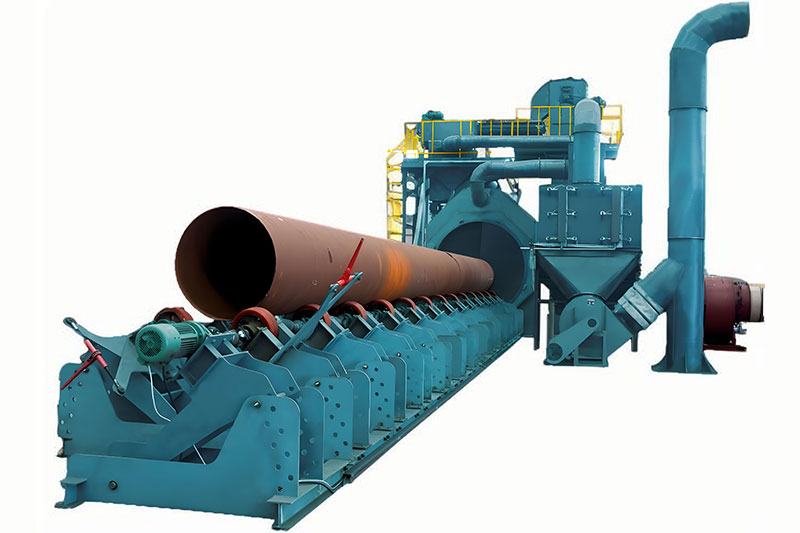

QH Series

QH Series

- Customized design;

- Modular design for shipping;

- Speed adjustable from 5m/min to 4m/min;

- Automatic PLC control;

- Wear-resistant manganese steel liner, lifetime is around 15000 hours;

- Automatic abrasive recycle system;

Quote Now

Product Parameters

Applications

Cleaning, Corrosion Removal, Paint Stripping, Rust and welding stress relief l for large beams and structures.

Main Benefits

- Customized design;

- Modular design for shipping;

- Speed adjustable from 5m/min to 4m/min;

- Automatic PLC control;

- Wear-resistant manganese steel liner, lifetime is around 15000 hours;

- Automatic abrasive recycle system;

Model & Specification

| ITEM / MODEL | QH698 | QH6912 | QH6920 | QH6925 |

| Workpiece width | ≤800mm | ≤1200mm | ≤2000mm | ≤2500mm |

| Workpiece height | ≤1200mm | ≤1500mm | ≤250mm | ≤3000mm |

| Entrance size | W800xH1200mm | W1200xH1500mm | W2000xH2500mm | W2500xH3000mm |

| Workpiece length | 1-12m | 1-12m | 1-12m | 1-12m |

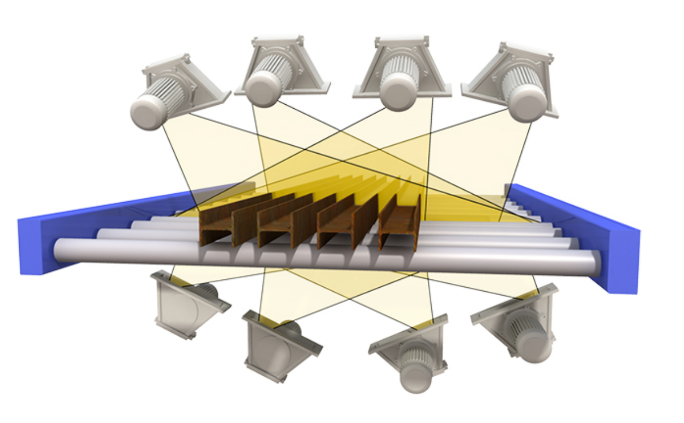

| Turbine quanity | 4 | 6 | 8 | 10/12 |

| Turbine motor power | 7.5 / 11 kw | 11/15 kw | 11/15 kw | 15 / 18.5kw |

| Roller length | 6m-14m | 6m-14m | 6m-14m | 6m-14m |

| Foundation | with pit | with pit | with pit | with pit |

| Total power | about 70 kw | about 140 kw | about 170kw | about 220kw |

| Abrasive used | S330, S280 | S330, S390 | S330, S390 | S330, S390 |

| Dust collector | 12 Cartridge filters | 24 Cartridge filters | 30 Cartridge filters | 36 cartridge filters |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

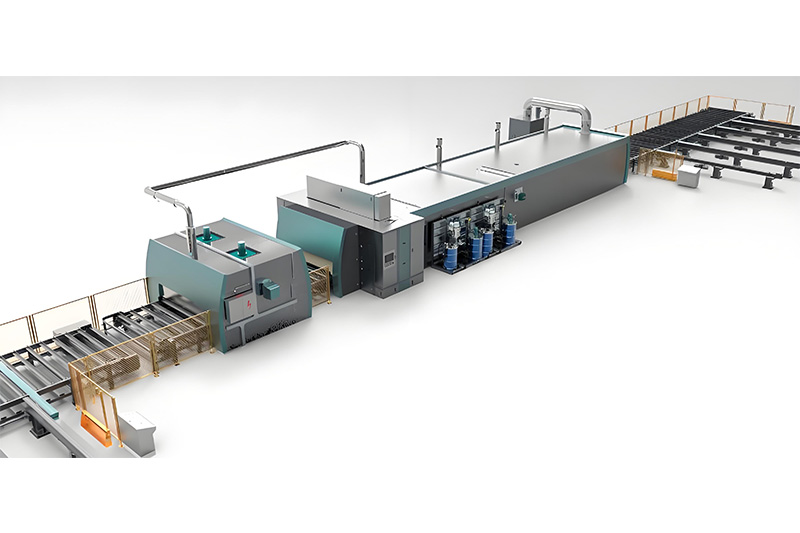

Modular design for easy shipping

- Roller conveyor shot blasting machine is mainly used to clean steel plates, profiles and structures by continuous pass through.

- The machine is made to several main parts by modular design.

- You need professional installation and commissioning.

- Foundation pit needed.

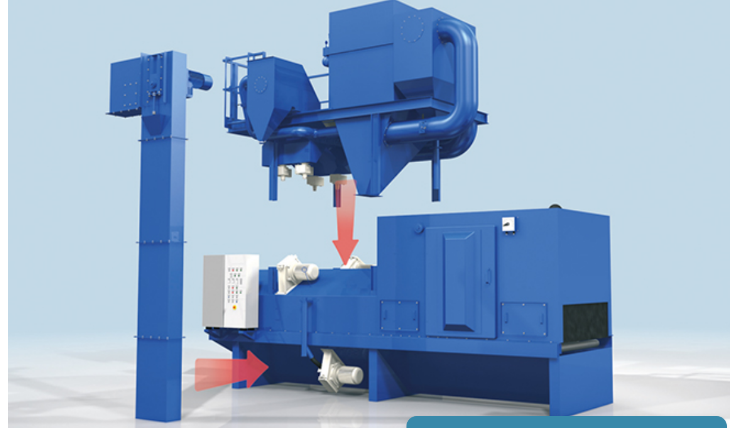

Belt Drive Blast Wheel

- Angled wheel arrangement

- Belt driven motor

- Eco motor optional

- High speed abrasive throw

- Thorough cleaning of metal surface

- High chrome wear resistant parts

Shot Blasting Cabinet

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement

- Friendly maintenane

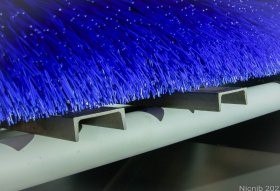

Efficient removal of abrasive

- Rotary brush and blow-off the abrasive

- Clean surface for further processing

- Adjustable height to suit different workpieces

Easy maintenance

- Easy take-out rubber seal curtain

- Fast maintenance

- Wear resistant rubber material