- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

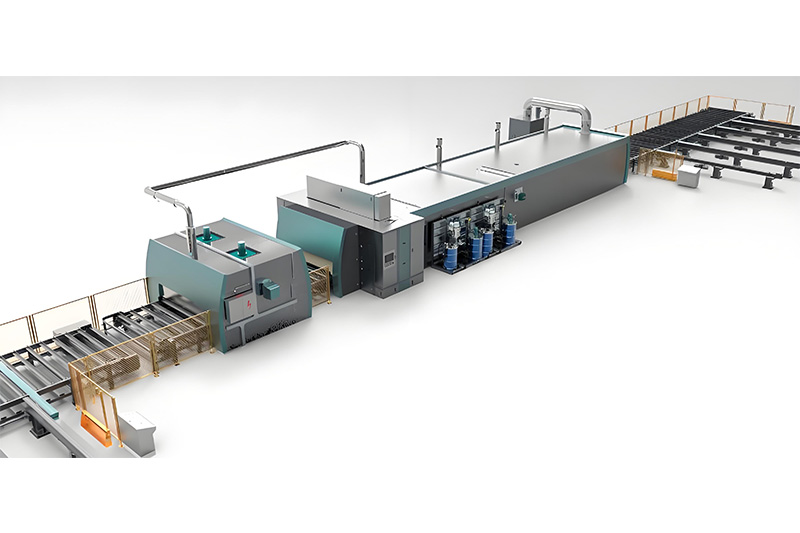

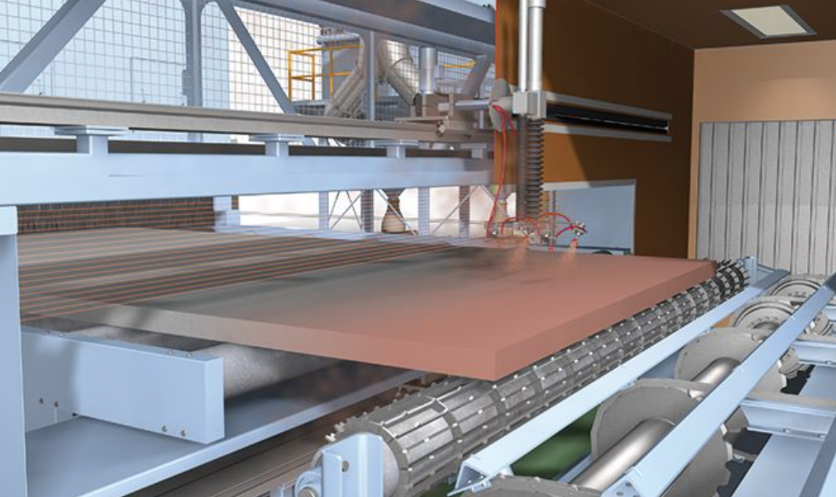

Preservation Line

Preservation Line

- Blasting, painting and drying in one go

- Direct flame and hot air circulation pre heating ovens

- Treat plate widths between 1.5 and 5m, with working speeds of 0.5 – 1.0 m/min

- Automatic width detection and wheel adjustment

- Automatic PLC control;

- Wear-resistant manganese steel liner, lifetime is around 15000 hours

- Energy saving design

Quote Now

Product Parameters

Applications

A preservation line is a highly complex, individually configured surface treatment system that fully automatically pre-heats, derusts, and descales and then applies a temporary corrosion protection – the welding primer – to steel. They are used where large quantities of steel sheets or profiles have to be processed (e.g. in shipyards, steel trades, or rolling mills).

Main Benefits

- Blasting, painting and drying in one go

- Direct flame and hot air circulation pre heating ovens

- Treat plate widths between 1.5 and 5m, with working speeds of 0.5 – 0 m/min

- Automatic width detection and wheel adjustment

- Automatic PLC control;

- Wear-resistant manganese steel liner, lifetime is around 15000 hours

- Energy saving design

Model & Specification

| Model | QXY1500 | QXY2000 | QXY2500 | QXY3000 | QXY3500 | QXY4000 | |

| Steel plate | Width | 500-1500 | 1000-2000 | 1000-2500 | 1000-3000 | 1000-3500 | 1000-4000 |

| Thickness | 3-20 | 3-60 | 5-30 | 3-60 | 5-35 | 5-50 | |

| Length | 2000-12000 | 1500-12000 | 2000-12000 | 2400-12000 | 2000-12000 | 2400-16000 | |

| H beam | Max. width | 1600 | 800 | 2500 | 1500 | 3500 | 4000 |

| Max. height | 500 | 300 | 400 | 800 | 400 | 500 | |

| Max. length | 2000-12000 | 2400-12000 | 2000-12000 | 2400-12000 | 2000-12000 | 2400-16000 | |

| Roller conveyor | Permissible load | 1 | 1 | 1.5 | 2 | 2 | 2 |

| speed | 2-4 | 1-5 | 2-4 | 0.5-4 | 2-4 | 2-4 | |

| Total power | 450 | 413.2 | 550 | 614 | 560 | 600 | |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

Preheating chamber

- Heating source: infrared or natural gas;

- Heating hot air recycled to drying chamber;

- Width and height sensor to wheel adjustment;

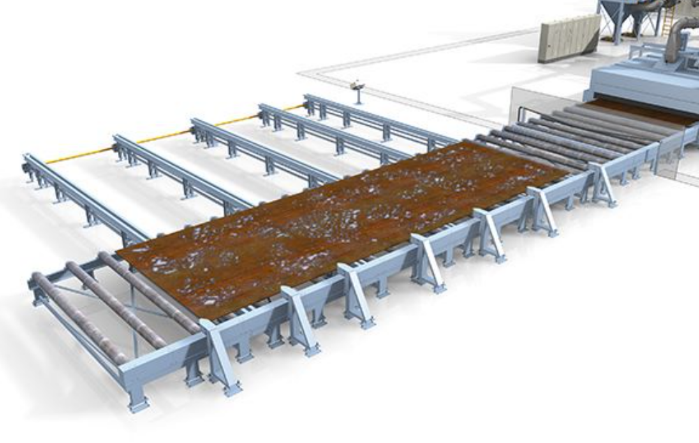

Cross Conveyor System

- Hydraulic power driven;

- Loading and unloading area;

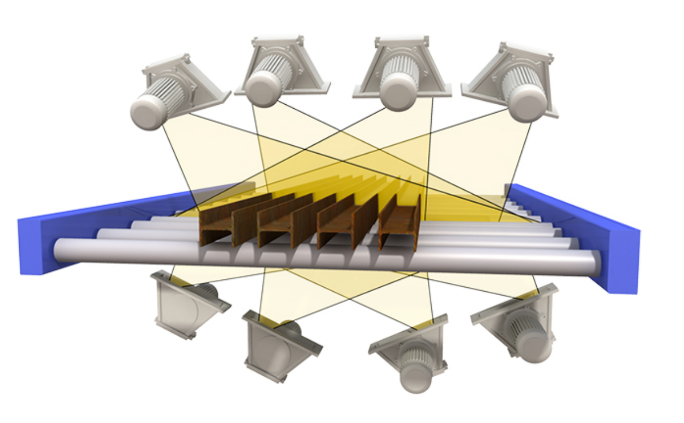

Belt Drive Blast Wheel

- Angled wheel arrangement

- Belt driven motor

- Eco motor optional

- High speed abrasive throw

- Thorough cleaning of metal surface

- High chrome wear resistant parts

Shot Blasting Cabinet

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement

- Friendly maintenane

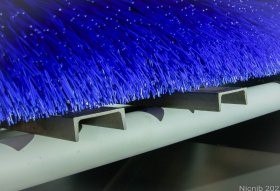

Efficient removal of abrasive

- Rotary brush and blow-off the abrasive

- Clean surface for further processing

- Adjustable height to suit different workpieces

Automatic painting chamber

- GRACO airless spraying gun;

- Overspray reduction through sensor scanning of the work pieces;

- Coating thickness adjustable;