- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

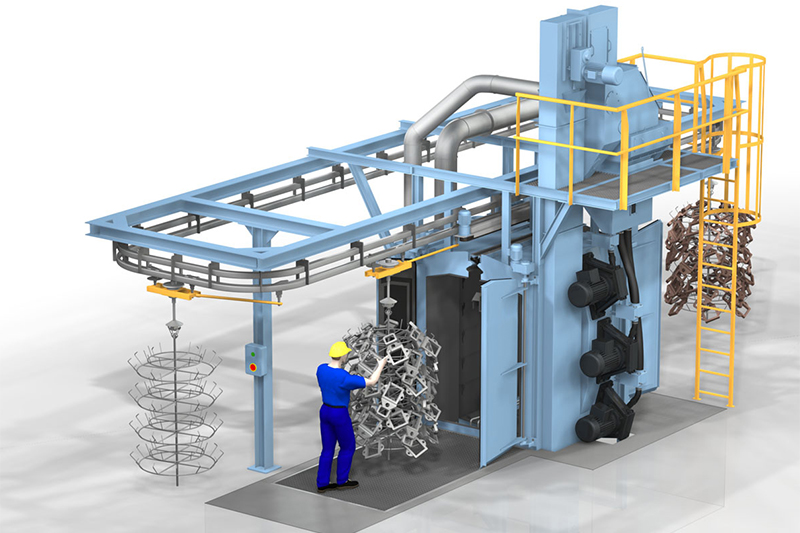

Closed loop monorail type shot blasting machine

Closed loop monorail type shot blasting machine

- Latest transport technology

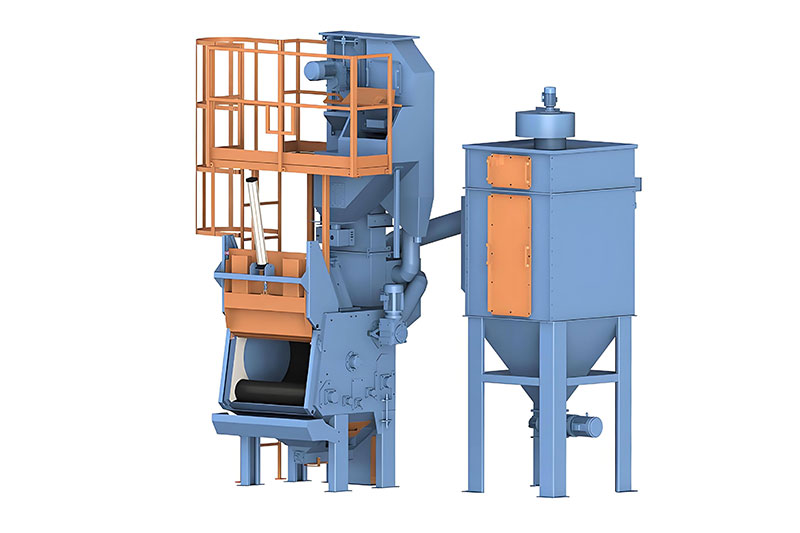

- Highly efficient blast wheels

- Short blast times

- Touch screen operator interface and integrated PLC optional;

- The blasting chamber is protected by wear-resistant manganese steel liner.

- A zigzag nylon brush and polyurethane strop sealing device on top of the chamber ensures no emission of abrasive and dust flying out from the blasting chamber.

Product Parameters

Applications

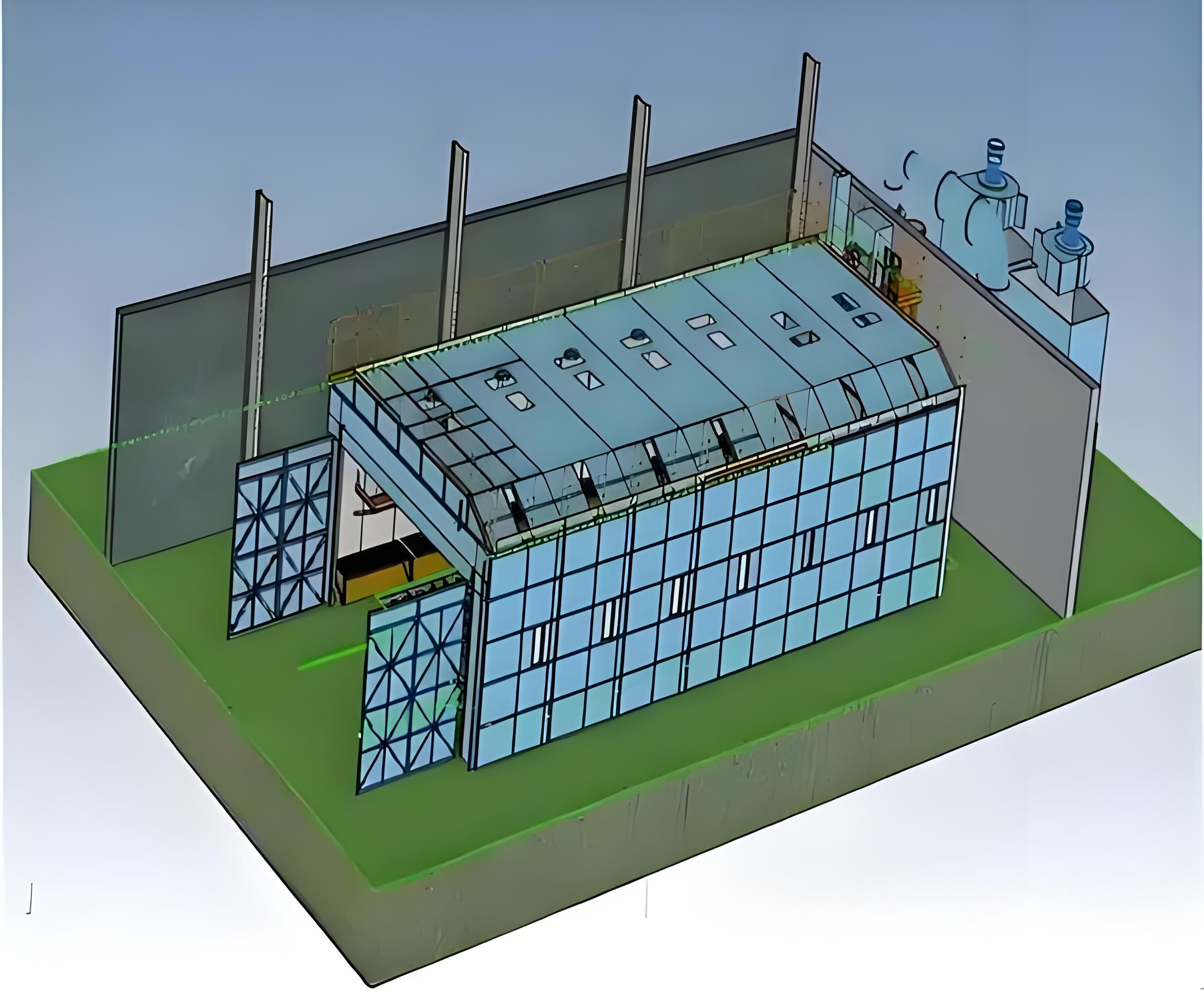

Closed loop monorial conveyor blast machines are among the most flexible blast machine types. They are used for a variety of workpieces for derusting, descaling, final sanding, deburring and finish blasting of sensitive components or for roughening surfaces for subsequent coating.

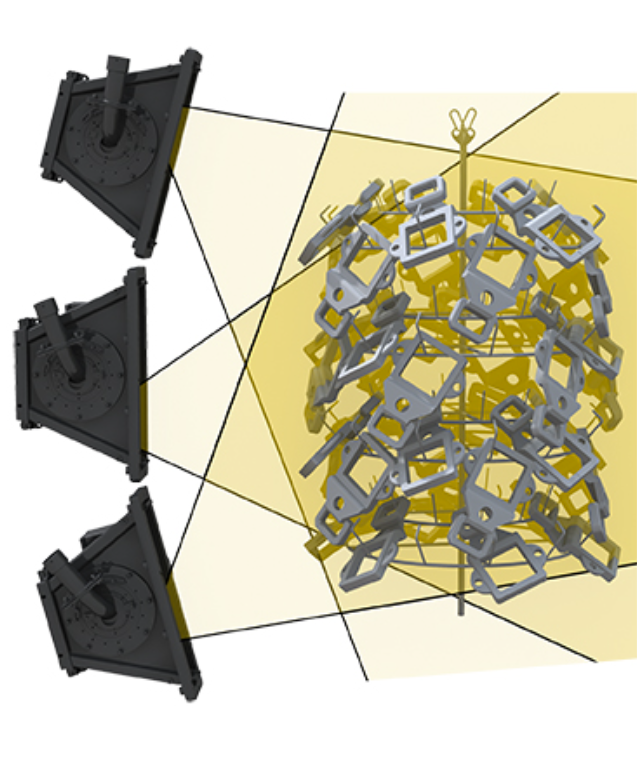

Workpiece changeover is carried out semi-automatically or automatically by the Power & Free system. The closed loop blast machine is provided with a rotating device on the monorail which rotates the loaded workpiece carriers in front of the turbines. This means that blast wheels need only be installed on one side of the blast cabin which lowers maintenance and energy expenses.

Main Benefits

- Latest transport technology

- Highly efficient blast wheels

- Short blast times

- Touch screen operator interface and integrated PLC optional;

- The blasting chamber is protected by wear-resistant manganese steel liner.

- A zigzag nylon brush and polyurethane strop sealing device on top of the chamber ensures no emission of abrasive and dust flying out from the blasting chamber.

Model & Specification

| No | Item | step moving type shot blasting machine | Continuous moving shot blast machine | ||||

| Q483 | Q485 | Q4810 | Q583 | Q5810 | |||

| 1 | Max weight of piece | kg | 300 | 500 | 800 | 300 | 1000 |

| 2 | Size of workpiece | mm | 1000*1400 | 1200*1700 | 700*2400 | 1000*1500 | 750*2400 |

| 3 | Abrasive flow rate | kg/m | 2*250 | 3*250 | 6*360 | 4*250 | 6*360 |

| 4 | Productivity | Hook/h | 10 | 10 | 10 | 30-60 | 50 |

| 5 | Speed of chain | m/min | 2.44 | 7.34 | 2.44 | Converter speed | |

| 6 | Lifting distance of pendant chain | mm | 2560 | 2560 | 2560 | 1000 | |

| 7 | Ventilation capacity | M3/h | 6000 | 10000 | 25000 | 18000 | 25000 |

| 8 | Power(not include dust collector) | kw | 38.75 | 58.43 | 85 | 127.25 | 160 |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

- Rubber sheet + nylon brush sealing

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

- Long lifetime Manganese protection liner

- Through bolted design, easy replacement

- The conveyor consists of a chain and trolley system;

- The conveyor also can consist of chain and hoists;

- It can be driven at constant speed or can be indexed;