Abrasive circulation clogging halts shot blasting; practical tips ensure smooth machine shot operation.

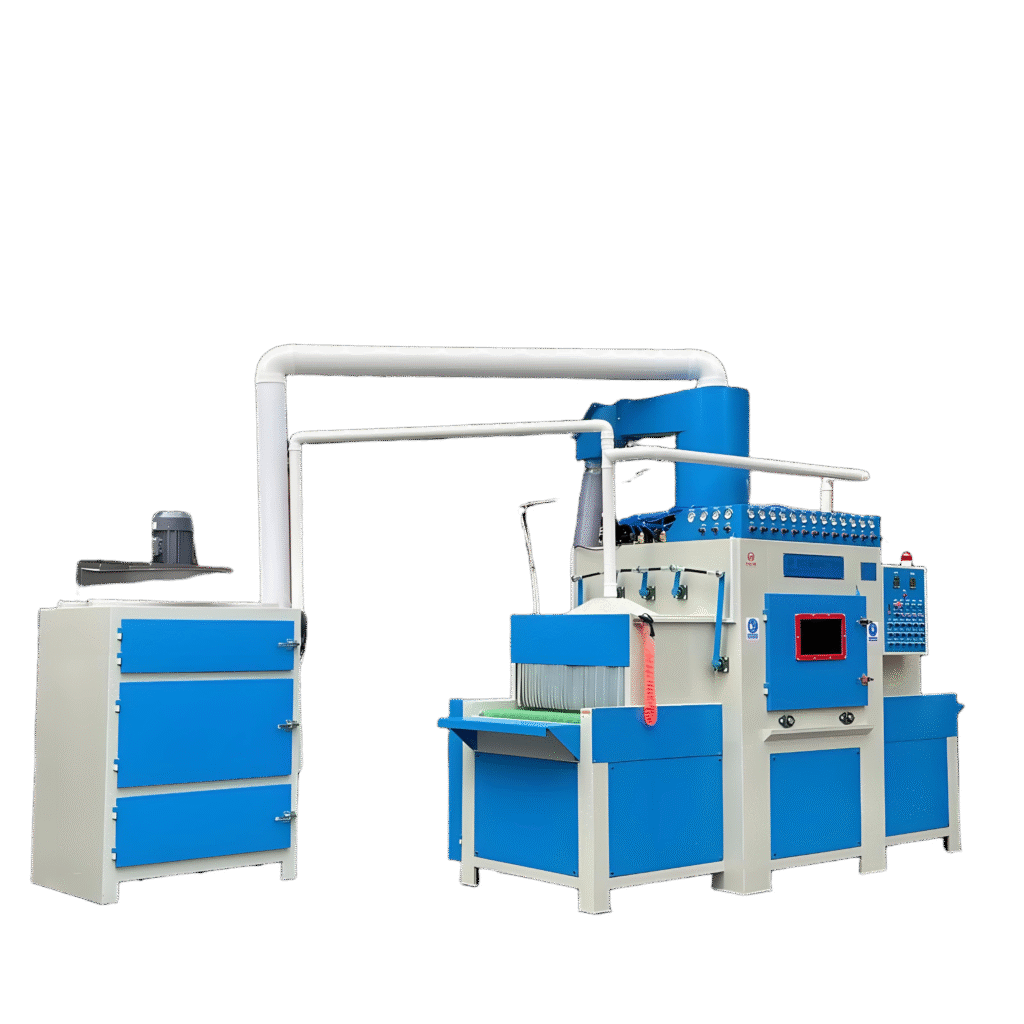

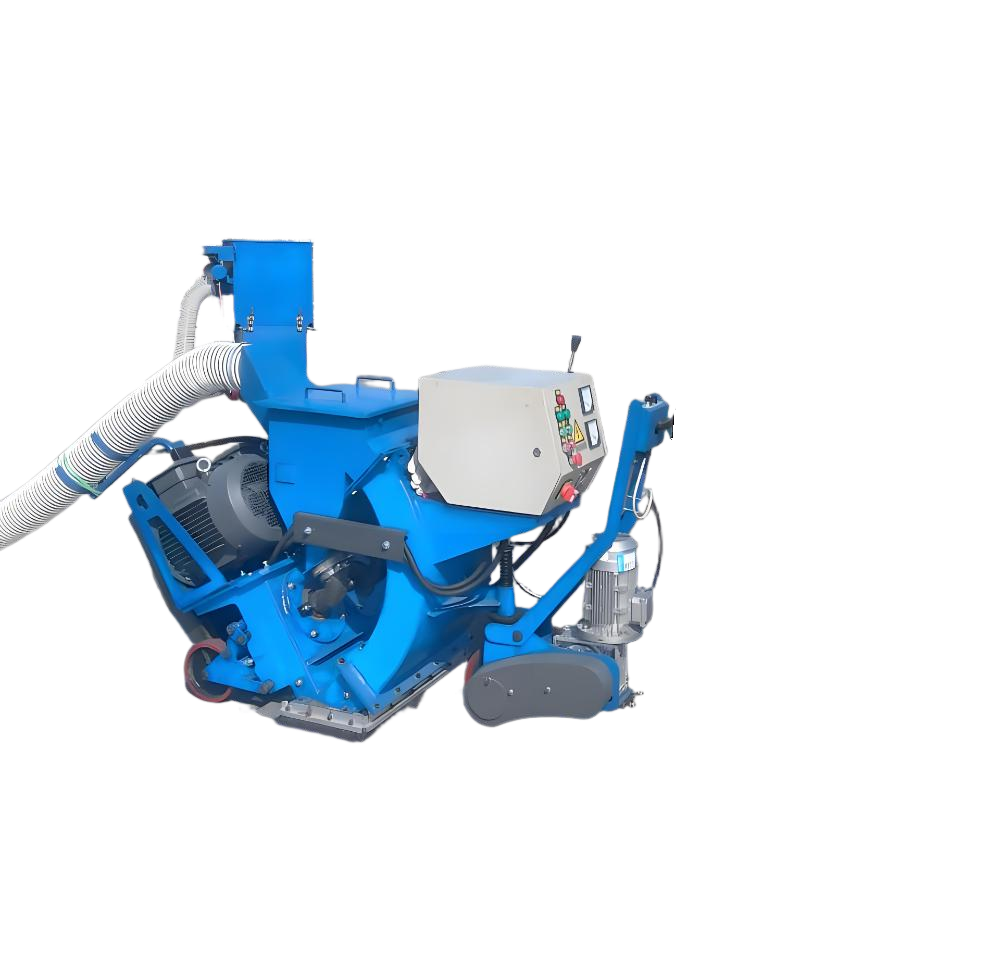

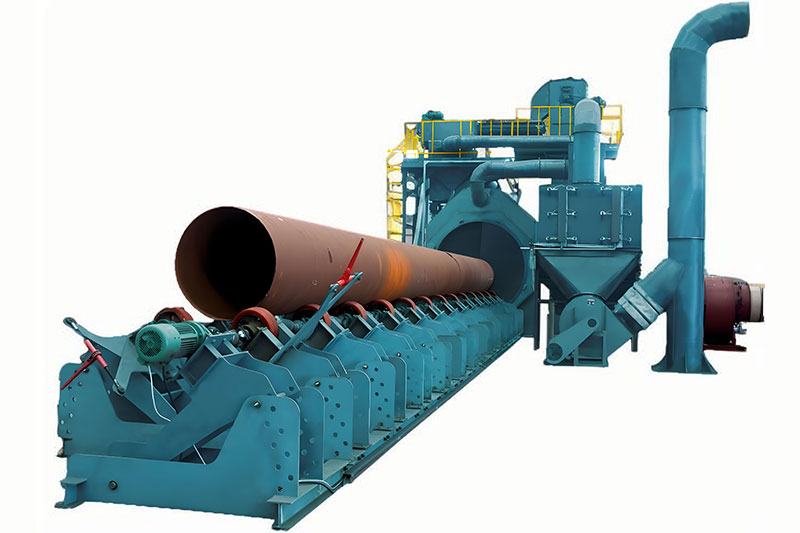

This guide shares practical tips to prevent clogging in shot blasting machine abrasive circulation, ensuring efficient and stable shot blast operations.

Explore key anti-clogging tips for shot blasting machine abrasive circulation below.

How to Select Suitable Abrasives to Avoid Circulation Clogging?

Selecting the right abrasive is the foundation to prevent clogging in the abrasive circulation system of a shot blasting machine. The core is to choose abrasives with uniform particle size, appropriate hardness, and good fluidity, which can effectively reduce the risk of accumulation and blockage during machine shot.

- Control particle size uniformity: avoid mixing oversized, undersized, or irregularly shaped abrasive particles, as they are prone to getting stuck in pipelines, hoppers, or nozzles. For most shot blast operations, select abrasives with a particle size range of 0.8-2.0mm, and use a multi-layer sieve to filter out impurities before adding them to the shot blasting machine.

- Match abrasive hardness with workpiece material: overly soft abrasives are prone to breaking into fine debris during shot blasting, which can clog the circulation pipeline; overly hard abrasives cause excessive wear to the circulation system, leading to component damage and subsequent clogging.

- Prioritize abrasives with good fluidity:such as spherical steel shot, which flows more smoothly than angular steel grit, reducing the chance of adhesion and accumulation in the circulation system. Proper abrasive selection can reduce circulation clogging by 40% and extend the service life of the shot blasting machine.

How to Optimize Shot Blasting Machine Circulation Structure to Prevent Clogging?

Optimizing the circulation structure of the shot blasting machine is a long-term and effective measure to avoid abrasive clogging, targeting key components of the circulation system.

- Optimize the pipeline design: replace narrow, sharp-bend pipelines with large-diameter pipelines with smooth transitions, and maintain a slope of 30-45° to ensure that abrasives can flow smoothly under gravity, reducing retention. Install anti-clogging vibrators on the hopper, chute, and pipeline joints—regular vibration can break up agglomerated abrasives and prevent residue buildup.

- Upgrade the abrasive screening and separation mechanism: add a built-in multi-layer sieve in the shot blasting machine to filter out broken abrasives, debris, and impurities in real time during circulation, preventing them from entering the pipeline and causing clogging. For the impeller head, a core component of the shot blasting machine, adjust the blade angle and rotation speed to match the abrasive flow rate, avoiding abrasive backflow and clogging at the discharge port.

- Adopt a modular circulation system design:which allows for easy disassembly and cleaning, making it convenient to clear clogs quickly when they occur and reducing maintenance downtime. These structural optimizations can fundamentally reduce the risk of abrasive clogging during shot blast operations.

How to Adjust Machine Shot Parameters to Avoid Abrasive Circulation Clogging?

Reasonable adjustment of machine shot parameters is a cost-effective way to prevent abrasive circulation clogging, ensuring that the circulation system operates within its optimal load range.

- Control the abrasive flow rate: according to the model of the shot blasting machine and the requirements of shot blast operations, adjust the feeding valve to keep the abrasive flow rate within 80% of the system’s maximum handling capacity. Excessive flow rate will overload the circulation system, leading to abrasive backlog and clogging; insufficient flow rate will reduce work efficiency and may cause abrasives to accumulate due to slow flow.

- Optimize the shot blasting pressure and impeller speed: excessively high pressure or speed will cause excessive collision between abrasives, increasing the number of broken abrasives and debris, which can clog the circulation system. Generally, adjust the shot blasting pressure to 0.6-0.8MPa and the impeller speed to 1500-2000rpm, balancing shot blast efficiency and circulation stability.

- Maintain stable feeding: ensure that abrasives are fed uniformly and continuously, avoiding intermittent feeding which can cause uneven abrasive flow and local accumulation in the circulation pipeline.

Regularly calibrate the flow meter and pressure gauge to maintain parameter stability, ensuring smooth abrasive circulation during shot blasting.

How to Perform Daily Maintenance to Prevent Abrasive Circulation Clogging?

Regular daily maintenance is crucial to avoid unexpected clogging and ensure the stable operation of the shot blasting machine’s abrasive circulation system.

- Establish a strict daily maintenance routine: after each shot blast operation, clean the circulation pipeline, hopper, sieve, and nozzle of the shot blasting machine to remove residual abrasives, debris, and dust that may cause clogging. Inspect the pipeline for wear, leaks, or loose connections—worn pipelines are prone to abrasive retention, and leaks may cause pressure loss and uneven flow.

- Conduct weekly maintenance: lubricate the moving parts of the circulation system, such as bearings, vibrators, and conveyor belts, to ensure smooth operation; check the wear of the sieve, impeller blades, and pipeline walls, and replace severely worn parts in time.

- Perform monthly maintenance: disassemble the key components of the circulation system for thorough cleaning and inspection, calibrate the vibrator frequency and feeding flow rate, and test the overall circulation efficiency.

Additionally, train operators to identify early signs of clogging, such as abnormal noise, reduced shot blast intensity, or uneven abrasive flow, and take timely measures to clear them, avoiding further damage to the shot blasting machine.

How to Handle and Prevent Recurrent Abrasive Circulation Clogging?

For recurrent abrasive circulation clogging, it is necessary to find the root cause and take targeted measures to prevent recurrence, ensuring long-term stable operation of the shot blasting machine.

- Analyze the cause of recurrent clogging: if clogging often occurs in the pipeline, it may be due to unreasonable pipeline design or excessive abrasive debris; if clogging occurs in the hopper, it may be due to damp abrasives or insufficient vibration. Through systematic inspection and data recording, clarify the location and frequency of clogging, and identify the fundamental cause.

- Take targeted solutions: for pipeline clogging caused by excessive debris, upgrade the screening mechanism and increase the frequency of debris cleaning; for hopper clogging caused by damp abrasives, install a drying device in the abrasive storage area to keep abrasives dry.

- Establish a clogging prevention management system: record the type of abrasive used, machine shot parameters, maintenance records, and clogging situations, summarize experience, and formulate targeted prevention plans.

Regularly train operators on clogging prevention skills and emergency handling methods, ensuring that they can quickly clear clogs and take preventive measures when problems occur. By addressing the root cause and strengthening management, recurrent abrasive circulation clogging can be effectively resolved.

Conclusion

Scientific selection, optimization and maintenance prevent shot blasting machine abrasive clogging.

For professional advice on shot blasting machine abrasive circulation anti-clogging,

contact us via email: [email protected]