Shot blasting dust and noise endanger workers; strict standards and measures guarantee safe operations.

This guide details dust/noise standards and protection for Wheelblast Equipment, securing shot blasting operations comprehensively.

Dive into detailed standards, measures and compliance tips for machine shot below.

What Are the Global and Domestic Dust Standards for Shot Blasting?

Shot blasting operations generate respirable and total dust, regulated by strict global and domestic standards. Internationally, the Occupational Safety and Health Administration (OSHA) mandates respirable dust ≤0.5mg/m³ and total dust ≤4mg/m³ for shot blasting. Domestic standards (GBZ 2.1-2019) align with global norms, applying to all Wheelblast Equipment. Dust from machine shot includes abrasive particles (steel shot/grit) and workpiece debris, which cause silicosis and other respiratory diseases with prolonged exposure. Enterprises must equip shot blasting machines with multi-stage dust removal systems to meet standards. Regular on-site detection (at least biweekly) ensures compliance; excess dust triggers immediate shutdown for rectification, protecting workers and avoiding environmental penalties.

What Are the Global and Domestic Noise Standards for Shot Blasting?

Wheelblast Equipment produces high noise during shot blasting, governed by stringent noise standards worldwide. The International Organization for Standardization (ISO) limits workplace noise to ≤85dB(A) for 8-hour daily exposure; exceeding this requires noise reduction or shortened exposure. Domestic standards (GBZ 2.2-2007) mirror ISO requirements, with residential area limits of ≤65dB(A) daytime and ≤55dB(A) nighttime. Noise from machine shot stems from abrasive impact, motor operation and impeller rotation. Prolonged exposure causes tinnitus, hearing loss and psychological stress. Enterprises must optimize equipment and adopt sound insulation measures to comply, with monthly noise monitoring to track and adjust operational parameters promptly.

How to Implement Comprehensive Dust Protection for Wheelblast Equipment?

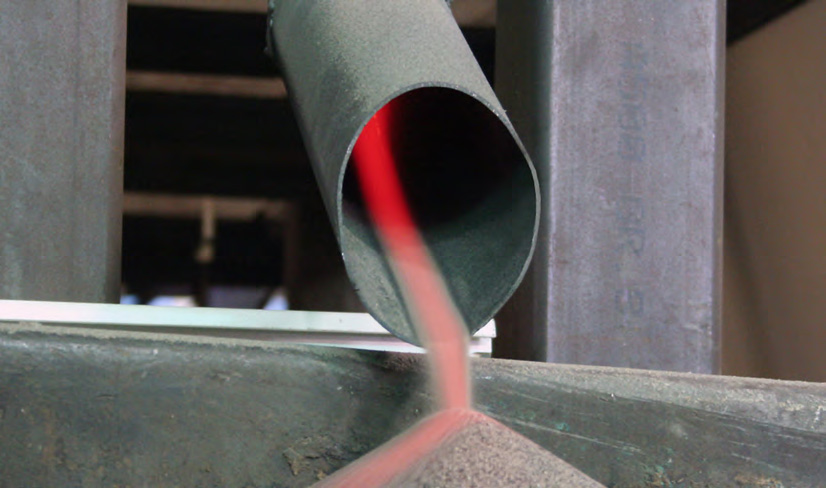

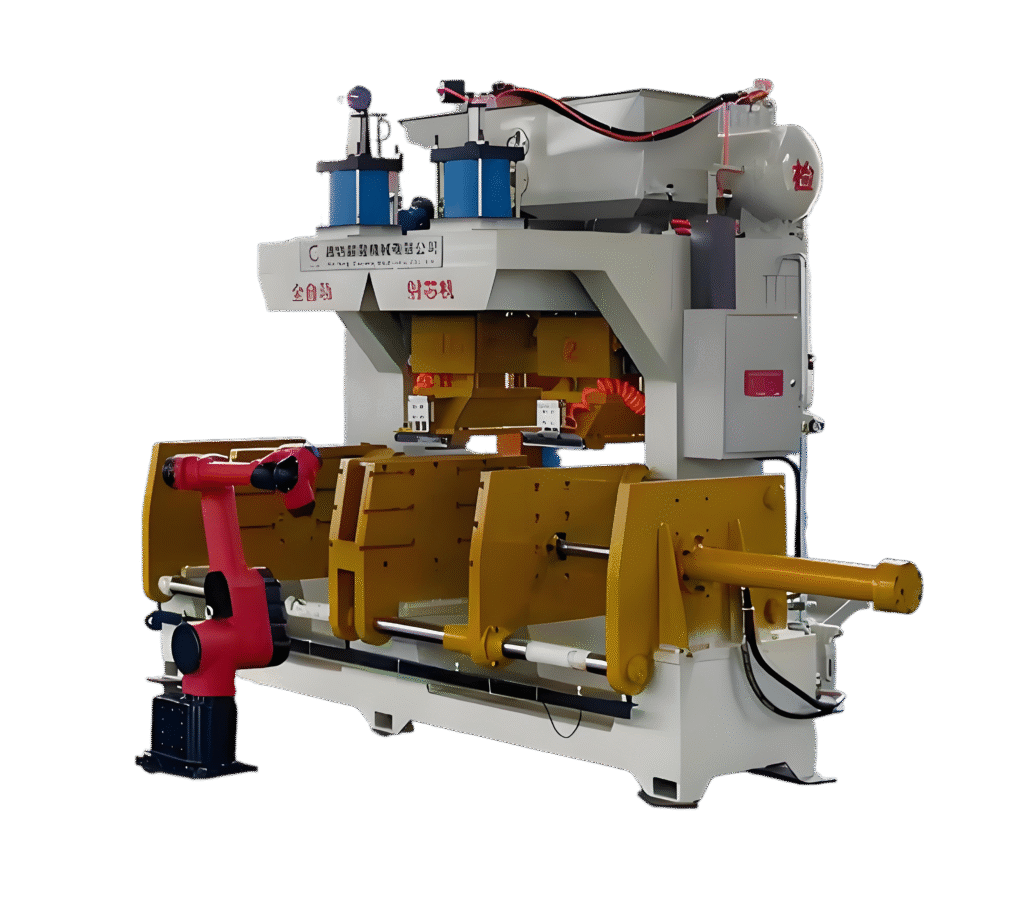

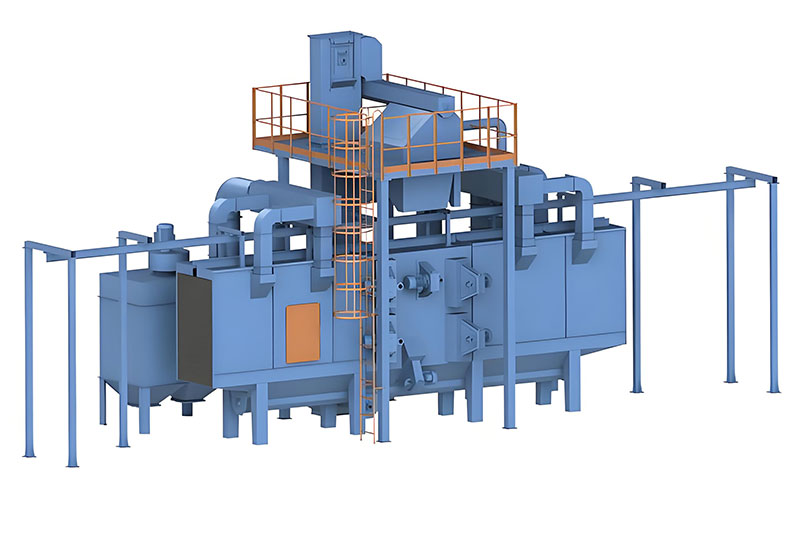

Dust protection for Wheelblast Equipment relies on a combination of equipment upgrades and operational norms. First, install high-efficiency dust removal systems: cyclone separators capture large abrasive particles (≥10μm), while HEPA filters trap fine dust (≤2.5μm), achieving 99.5%+ removal efficiency. Seal the machine’s shell, pipelines and nozzles with rubber gaskets to prevent dust leakage during shot blasting. Operators must wear N95+ dust masks, protective clothing and goggles to avoid direct exposure. Regularly clean and maintain dust removal systems (daily filter checks, weekly thorough cleaning) to ensure stability. Optimize machine shot parameters (reduce abrasive flow appropriately) to balance cleaning efficiency and dust control, forming a full-chain dust protection system.

How to Implement Effective Noise Protection for Wheelblast Equipment?

Noise protection for Wheelblast Equipment integrates structural optimization, auxiliary measures and worker protection. Wrap the machine’s shell with sound-absorbing cotton (50mm thickness) and damping steel plates to reduce noise transmission by 30-40%. Install detachable soundproof enclosures around high-noise components (motors, impeller heads) with noise reduction foam lining. Optimize impeller blade angles and nozzle designs to minimize vibration-induced noise during shot blasting. Operators wear noise-canceling headphones (noise reduction ≥25dB) and follow shift systems (max 4 hours continuous exposure). Lubricate rotating parts monthly to reduce friction noise, and replace worn blades/nozzles promptly—these parts exacerbate noise when damaged, ensuring equipment operates within standard limits.

How to Ensure Compliance with Dust/Noise Standards in Shot Blasting?

Ensuring compliance with dust/noise standards requires systematic management, monitoring and training. Install real-time monitoring devices on Wheelblast Equipment to track dust concentration and noise levels continuously, triggering audible/visual alarms for abnormalities. Establish a detailed record system (monitoring data, maintenance logs, training records) for inspection and traceability. Conduct annual third-party testing to verify compliance with national/international standards. Train operators pre-job and quarterly: teach hazard recognition, protective equipment use and emergency handling. Strengthen daily supervision to correct improper operations (e.g., unclosed soundproof enclosures) and conduct regular equipment overhauls, ensuring machine shot operations meet all safety and environmental requirements.

Conclusion

Abide by standards and take measures to safeguard shot blasting operations and workers.

For professional guidance on Wheelblast Equipment protection and compliance,

contact us via email:[email protected]