Wheelblast Equipment vibration and noise harm workers and equipment; practical measures solve these problems effectively.

This guide details practical vibration and noise reduction methods for Wheelblast Equipment, ensuring safe and stable shot blasting operations.

Explore specific methods and key points for machine shot vibration and noise reduction below.

What Are the Main Sources of Vibration and Noise in Wheelblast Equipment?

To implement effective vibration and noise reduction, it is first necessary to clarify their main sources in Wheelblast Equipment. Vibration mainly comes from three aspects:

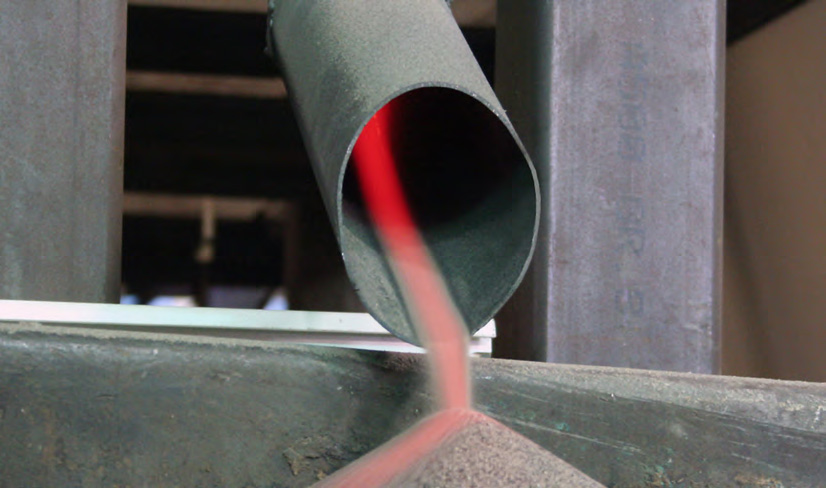

- The high-speed rotation of the impeller head during machine shot, which causes unbalanced centrifugal force and triggers equipment vibration;

- The impact of abrasive on the workpiece and the inner wall of the equipment during shot blasting, generating impact vibration that spreads to the whole machine;

- The unstable operation of the motor and transmission system, such as loose bearings or uneven power output, leading to additional vibration.

Noise sources are closely related to vibration: the high-speed rotation of the impeller and the impact of abrasive during shot blasting produce aerodynamic noise and impact noise, accounting for 70% of the total noise; the motor, fan and other components generate mechanical noise; the vibration of the equipment shell and pipeline produces structural radiation noise. Understanding these sources provides a targeted direction for subsequent vibration and noise reduction.

How to Implement Foundation Vibration Reduction for Wheelblast Equipment?

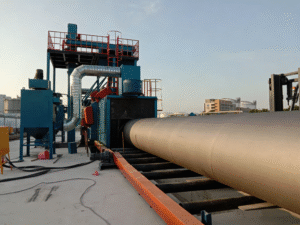

Foundation vibration reduction is the basic measure to control the vibration of Wheelblast Equipment, and it needs to be implemented in combination with the equipment model and on-site conditions.

- Design a dedicated vibration reduction foundation: according to the weight and vibration intensity of the equipment, pour a reinforced concrete foundation with a thickness of not less than 30cm, and set a vibration isolation layer between the foundation and the ground. The vibration isolation layer can be made of rubber pads, damping rubber or asphalt felt, with a thickness of 5-10cm, which can effectively absorb vibration and prevent it from spreading to the surrounding environment.

- Ensure the levelness and stability of the foundation: during installation, use a level meter to calibrate the foundation, avoid uneven force on the equipment, which may lead to increased vibration.

- Fix the equipment firmly: use high-strength anchor bolts to connect the Wheelblast Equipment to the foundation, and add shock-absorbing washers between the bolts and the equipment base to reduce vibration transmission. For large-scale Wheelblast Equipment, additional anti-vibration beams can be installed around the foundation to enhance the stability of the foundation and further reduce vibration amplitude during shot blasting.

How to Reduce Vibration by Optimizing Wheelblast Equipment Structure?

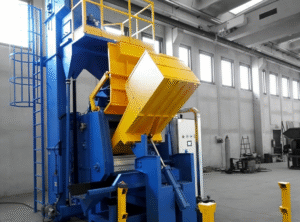

Optimizing the structure of Wheelblast Equipment is an effective way to reduce vibration from the source, which is suitable for both new equipment and old equipment renovation.

- Optimize the impeller head structure: select high-precision balanced impellers, and conduct dynamic balance detection before installation to ensure that the impeller rotates stably without unbalanced centrifugal force; replace worn blades and shot wheels in time, as uneven wear will cause unbalanced rotation and increase vibration.

- Improve the equipment shell and inner lining: install wear-resistant and shock-absorbing lining plates (such as polyurethane lining plates) on the inner wall of the equipment, which can absorb the impact of abrasive during machine shot, reduce impact vibration, and also reduce noise; reinforce the equipment shell with steel plates to improve its rigidity, avoid vibration and noise caused by shell deformation.

- Optimize the transmission system: use flexible couplings to connect the motor and the impeller head, which can absorb the vibration generated by the motor and reduce the transmission of vibration to the impeller; regularly lubricate the bearings and gears of the transmission system to reduce friction vibration, ensure smooth operation, and further reduce the overall vibration of the Wheelblast Equipment.

How to Implement Noise Reduction Measures for Wheelblast Equipment?

Noise reduction for Wheelblast Equipment needs to adopt comprehensive measures combining source control, transmission isolation and absorption.

- Control noise from the source: optimize machine shot parameters, appropriately reduce the impeller speed and abrasive flow rate under the premise of ensuring shot blasting efficiency, which can reduce impact noise and aerodynamic noise; select low-noise motors and fans, and install mufflers at the air inlet and outlet of the fan to reduce mechanical noise and aerodynamic noise.

- Isolate noise transmission: install a detachable sound insulation enclosure around the Wheelblast Equipment, the enclosure is made of double-layer steel plates with sound-absorbing cotton (thickness of 5-8cm) filled in the middle, which can reduce noise transmission by 30-40%; wrap the equipment pipeline with sound-absorbing tape or damping cloth to reduce noise generated by pipeline vibration.

- Strengthen noise absorption: install sound-absorbing panels on the inner wall of the workshop where the Wheelblast Equipment is located, and lay sound-absorbing floor tiles on the ground to absorb the scattered noise in the air; set up sound insulation barriers around the equipment if necessary, especially in areas close to the operation position, to protect workers from noise harm.

How to Maintain Vibration and Noise Reduction Effects of Wheelblast Equipment?

The vibration and noise reduction effect of Wheelblast Equipment needs regular maintenance to avoid performance degradation caused by wear or improper operation.

- Establish a daily inspection system: after each shot blasting operation, check the vibration isolation layer, sound insulation enclosure and other components, and replace the aging or damaged rubber pads, sound-absorbing cotton in time; check the tightness of the equipment bolts and the wear of the impeller blades, and tighten or replace them in time to avoid increased vibration and noise.

- Conduct regular detection: use vibration meters and noise meters to detect the vibration amplitude and noise level of the equipment every week, compare with the standard value, and find out the abnormal situation in time to analyze the cause and handle it.

- Strengthen operator training: guide operators to master the correct operation method of Wheelblast Equipment, avoid improper operation (such as overloading, idling) leading to increased vibration and noise; let operators understand the importance of vibration and noise reduction maintenance, and timely report equipment abnormalities. Regular maintenance can ensure that the vibration and noise reduction measures of the equipment are always in good condition, and maintain long-term stable shot blasting operation.

Conclusion

Practical foundation, structure and maintenance measures reduce Wheelblast Equipment vibration and noise.

For professional Wheelblast Equipment vibration and noise reduction solutions,

contact us via email: [email protected]