Unstable projectile speed affects shot blasting quality; precise control methods ensure consistent machine shot results.

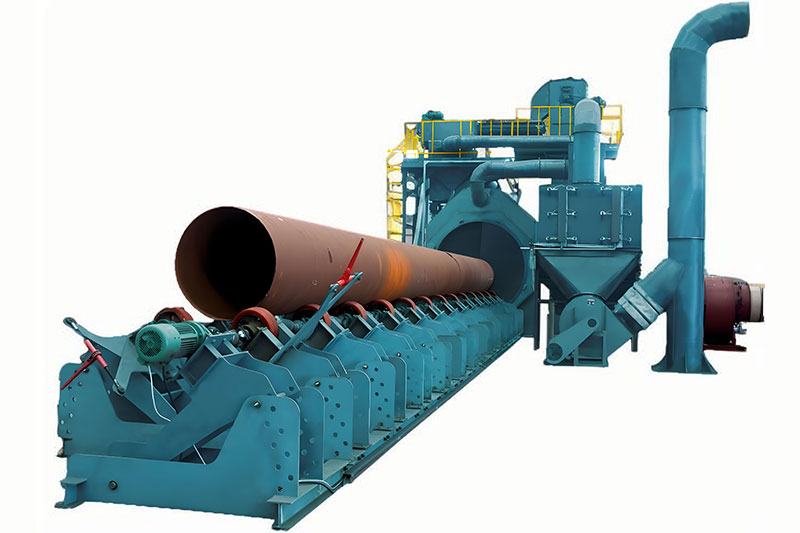

This guide details precise projectile speed control methods for Wheelblast Equipment and shot blasting machines, ensuring high-quality shot blasting operations.

Explore practical control methods and key points for stable machine shot speed below.

Why Is Precise Projectile Speed Control Important for Shot Blasting?

Precise control of projectile speed is a core requirement for high-quality shot blasting operations, directly affecting workpiece processing effects, equipment service life, and operational efficiency of Wheelblast Equipment and shot blasting machines. During machine shot, excessively high projectile speed will cause over-blasting, leading to workpiece surface damage, excessive wear of equipment components (such as impeller blades and nozzles), and increased energy consumption. On the contrary, excessively low projectile speed cannot meet the surface cleaning, derusting, or strengthening requirements of the workpiece, resulting in rework, reduced production efficiency, and wasted abrasives. For different workpieces (such as castings, steel structures, and precision components), the required projectile speed varies significantly—precise control ensures that the projectile speed matches the workpiece material and processing needs. Additionally, stable projectile speed reduces equipment vibration and noise during shot blasting, extending the service life of the shot blasting machine and improving the working environment. In summary, precise projectile speed control is the key to balancing shot blasting quality, equipment stability, and operational cost.

How to Adjust Impeller Speed to Control Projectile Speed Precisely?

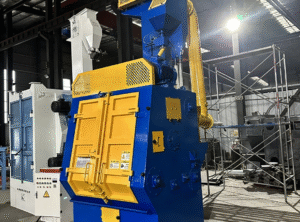

The impeller is the core component that determines projectile speed in Wheelblast Equipment and shot blasting machines, so adjusting impeller speed is the most direct and effective control method.

- Select a suitable speed regulation system: install a variable frequency drive (VFD) on the shot blasting machine’s motor, which can adjust the motor speed steplessly, thereby changing the impeller rotation speed and controlling projectile speed precisely. The VFD allows operators to set the target speed according to workpiece requirements, with an adjustment accuracy of ±5rpm, ensuring stable projectile speed.

- Calibrate the impeller speed and projectile speed correspondence: conduct a test run before formal shot blasting, record the corresponding projectile speed under different impeller speeds, and establish a parameter table for quick adjustment during actual operation. For example, when processing ordinary carbon steel workpieces, the impeller speed can be set to 1500-1800rpm, corresponding to a projectile speed of 60-70m/s; for precision components, reduce the impeller speed to 1200-1500rpm, with a projectile speed of 50-60m/s.

- Maintain the impeller in good condition: regularly inspect the impeller blades, shot wheel, and directional sleeve for wear, as uneven wear will cause unbalanced impeller rotation, leading to unstable projectile speed. Replace worn components in time and conduct dynamic balance detection on the impeller to ensure stable rotation, laying a foundation for precise speed control.

How to Optimize Machine Shot Parameters to Stabilize Projectile Speed?

In addition to impeller speed, other machine shot parameters also affect projectile speed stability, so optimizing these parameters is crucial for precise control.

- Control the abrasive flow rate reasonably: the abrasive flow rate directly affects the load of the impeller, and excessive flow rate will cause the impeller speed to drop, leading to reduced projectile speed; insufficient flow rate will cause uneven force on the impeller, resulting in unstable projectile speed. Install a flow control valve on the abrasive feeding pipeline, adjust the flow rate to 70-80% of the impeller’s maximum handling capacity, and use a flow meter to monitor in real time, ensuring stable feeding.

- Ensure the uniformity of abrasive particle size: mixed abrasives with uneven particle size will cause inconsistent acceleration by the impeller, leading to large fluctuations in projectile speed. Use a multi-layer sieve to filter abrasives before feeding, ensuring the particle size error is within ±0.2mm, so that each projectile can obtain the same acceleration.

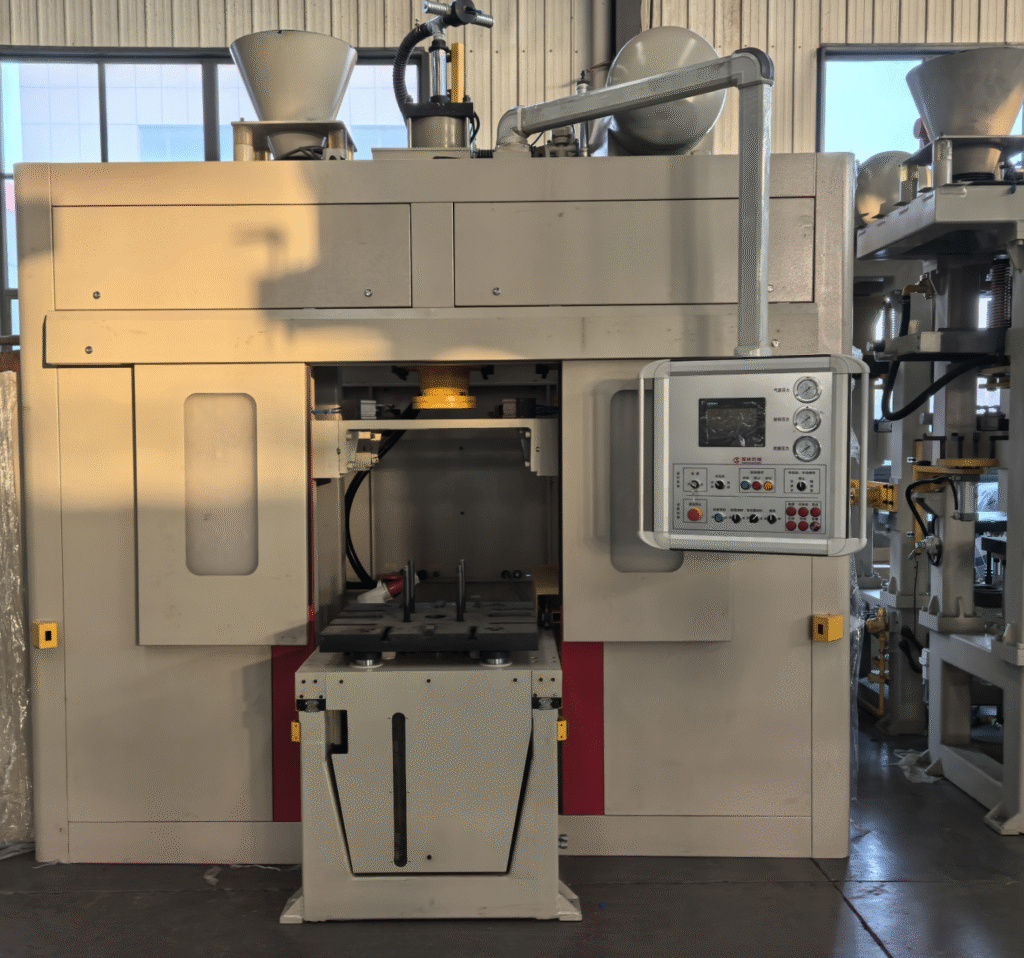

- Adjust the air pressure (for air blast shot blasting machines): for air blast type Wheelblast Equipment, air pressure is another key factor affecting projectile speed. Install a pressure regulator and pressure gauge, set the air pressure to 0.6-0.8MPa, and maintain stable pressure by adjusting the air compressor’s output, ensuring that abrasives are accelerated uniformly in the nozzle, achieving precise projectile speed control.

How to Use Detection Equipment to Monitor Projectile Speed in Real Time?

Real-time monitoring of projectile speed is the guarantee of precise control, so equipping the shot blasting machine with professional detection equipment is essential for Wheelblast Equipment and shot blasting operations.

- Select a suitable projectile speed detector: install an optical speed detector or laser speed detector at the impeller outlet of the shot blasting machine, which can detect the projectile speed in real time with an accuracy of ±1m/s, and display the data on the central control panel, allowing operators to monitor the speed status at any time.

- Set up an automatic alarm and adjustment system: connect the speed detector to the VFD and flow control valve, set the upper and lower limits of projectile speed (such as ±3m/s of the target speed), and if the detected speed exceeds the limit, the system will trigger an alarm and automatically adjust the impeller speed or abrasive flow rate to return the projectile speed to the target range.

- Conduct regular calibration of detection equipment: the speed detector may have measurement errors after long-term use, so calibrate it monthly using a standard speed measuring tool, ensuring the accuracy of detection data. Real-time monitoring and automatic adjustment can avoid manual operation errors, ensure that projectile speed remains stable during long-term shot blasting operations, and improve processing consistency.

How to Maintain Equipment to Ensure Long-Term Precise Control of Projectile Speed?

Long-term precise control of projectile speed relies on regular equipment maintenance, which can avoid performance degradation caused by equipment wear or failure, ensuring stable operation of Wheelblast Equipment and shot blasting machines.

- Establish a daily maintenance routine: after each shot blasting operation, clean the impeller, nozzle, and abrasive pipeline to remove residual abrasives and debris, which may cause blockages or uneven feeding, affecting projectile speed. Inspect the VFD, pressure gauge, flow meter, and speed detector for normal operation, and clean the sensor of the speed detector to avoid dust interference.

- Conduct weekly maintenance: lubricate the motor, impeller bearings, and other moving parts with high-temperature resistant grease to reduce friction, ensuring stable motor operation and impeller rotation. Check the tightness of the impeller fasteners and the wear of the directional sleeve, and adjust or replace them in time.

- Perform monthly maintenance: calibrate the VFD, speed detector, and pressure gauge, check the wiring of the electrical system to avoid contact failure, and test the overall performance of the shot blasting machine. Additionally, train operators to master the correct operation method and maintenance skills, guide them to identify early signs of equipment abnormalities (such as unstable speed, abnormal noise), and take timely measures to handle them, ensuring that the shot blasting machine can maintain precise projectile speed control for a long time.

Conclusion

Impeller speed adjustment, parameter optimization and maintenance ensure precise projectile speed control.

For professional guidance on Wheelblast Equipment projectile speed control,

contact us via email: [email protected]