- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

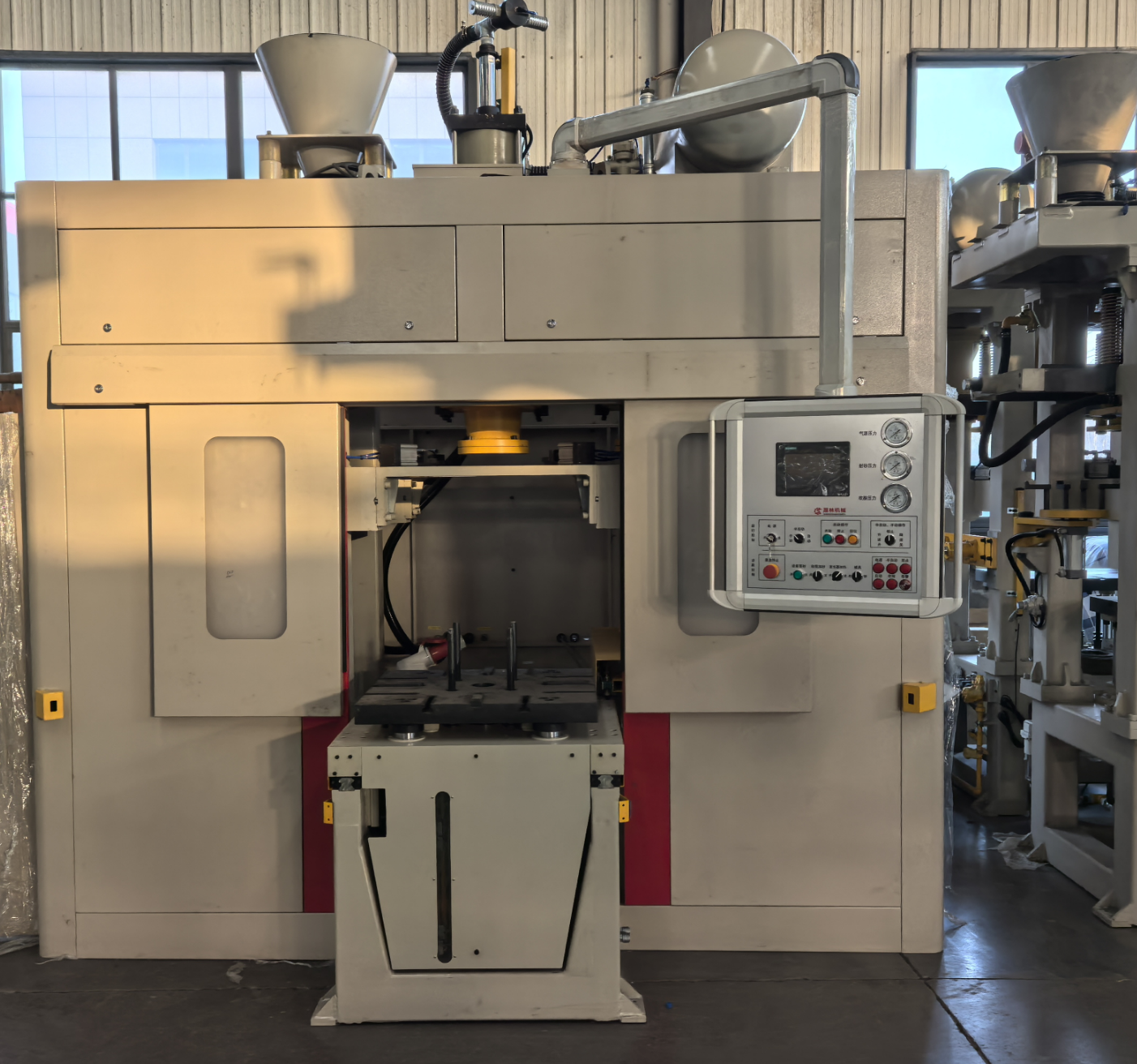

Cold box core making machine

Cold box core making machine

- Extremely Fast Curing: Seconds vs. minutes/hours needed for oven-baked (hot box, shell) or moisture-cured cores. Dramatically increases core production rates and overall foundry throughput.

- Exceptional Core Strength & Hardness: Produces cores with very high tensile, compressive, and shear strength immediately after curing. Minimizes core handling damage and breakage.

- Superior Dimensional Accuracy & Surface Finish: Allows production of extremely complex, thin-walled cores with excellent dimensional stability and very smooth surface finish. Reduces casting defects like veining and improves overall casting quality.

Quote Now

Product Parameters

Applications

A Cold Box Core Making Machine is a specialized automated foundry machine used to produce high-precision sand cores. It utilizes the cold box process, a core-making technology where sand mixed with binders is cured rapidly at room temperature using a gaseous catalyst.

Cold box machines are used wherever complex, high-strength, dimensionally accurate sand cores are required, especially for internal cavities and intricate passages in castings produced via sand casting. Major industries include:

- Automotive: Engine blocks, cylinder heads, intake manifolds, transmission housings, brake calipers, pump housings.

- Aerospace: Turbine housings, engine components, structural castings.

- Industrial Machinery: Hydraulic valve bodies, pump casings, compressor housings, gearboxes.

- Heavy Equipment: Engine components, transmission cases, axle housings.

- Pipe & Valve: Complex valve bodies, fittings.

- General Foundry Work: Any casting requiring high-integrity internal features.

Main Benefits

- Extremely Fast Curing: Seconds vs. minutes/hours needed for oven-baked (hot box, shell) or moisture-cured cores. Dramatically increases core production rates and overall foundry throughput.

- Exceptional Core Strength & Hardness: Produces cores with very high tensile, compressive, and shear strength immediately after curing. Minimizes core handling damage and breakage.

- Superior Dimensional Accuracy & Surface Finish: Allows production of extremely complex, thin-walled cores with excellent dimensional stability and very smooth surface finish. Reduces casting defects like veining and improves overall casting quality.

- High Productivity & Automation: Designed for high-speed, automated operation. Easily integrated into core room automation (robotic handling). Reduces labor costs per core.

- Low Energy Consumption (Compared to Thermal Processes): Doesn’t require massive ovens (like hot box/shell) or large drying areas (like CO₂), significantly reducing energy costs.

- Versatility in Binders: Compatible with various binder systems (Phenolic Urethane, Furan, Epoxy Acrylate cold box processes) allowing selection for specific casting needs (collapse, shakeout, emissions).

- Consistency & Repeatability: Automated process ensures highly consistent core quality, weight, and dimensions, minimizing casting scrap rates.

- Improved Working Environment (vs. Hot Box): Core boxes operate at or near room temperature, improving operator comfort and safety compared to hot box processes.

- Good Collapse Properties: Modern binder systems can be formulated to provide good collapsibility after casting, aiding core removal during shakeout.

- Reduced Odor (Compared to some older processes): While amine gases need handling, modern systems with efficient scrubbers significantly reduce workplace odor compared to processes like traditional shell or some furan binders.

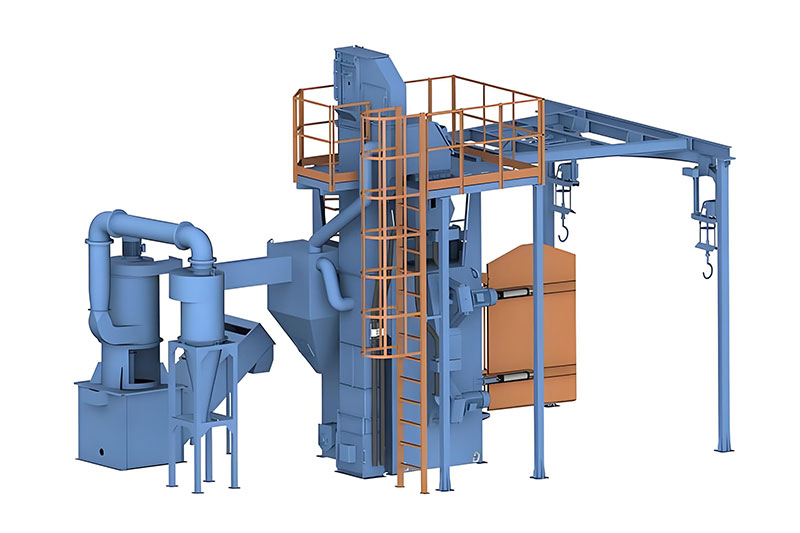

We make tailor made and turnkey project for core making system, you can contact and get the design for your particular needs.

Feature

CO2 technology core making system

- Use CO2 gas as the hardening gas to react chemically with the sodium silicate binder

Triethylamine technology core making machine

- Use Triethylamine gas as the hardening gas to react chemically with the sodium silicate binder