- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

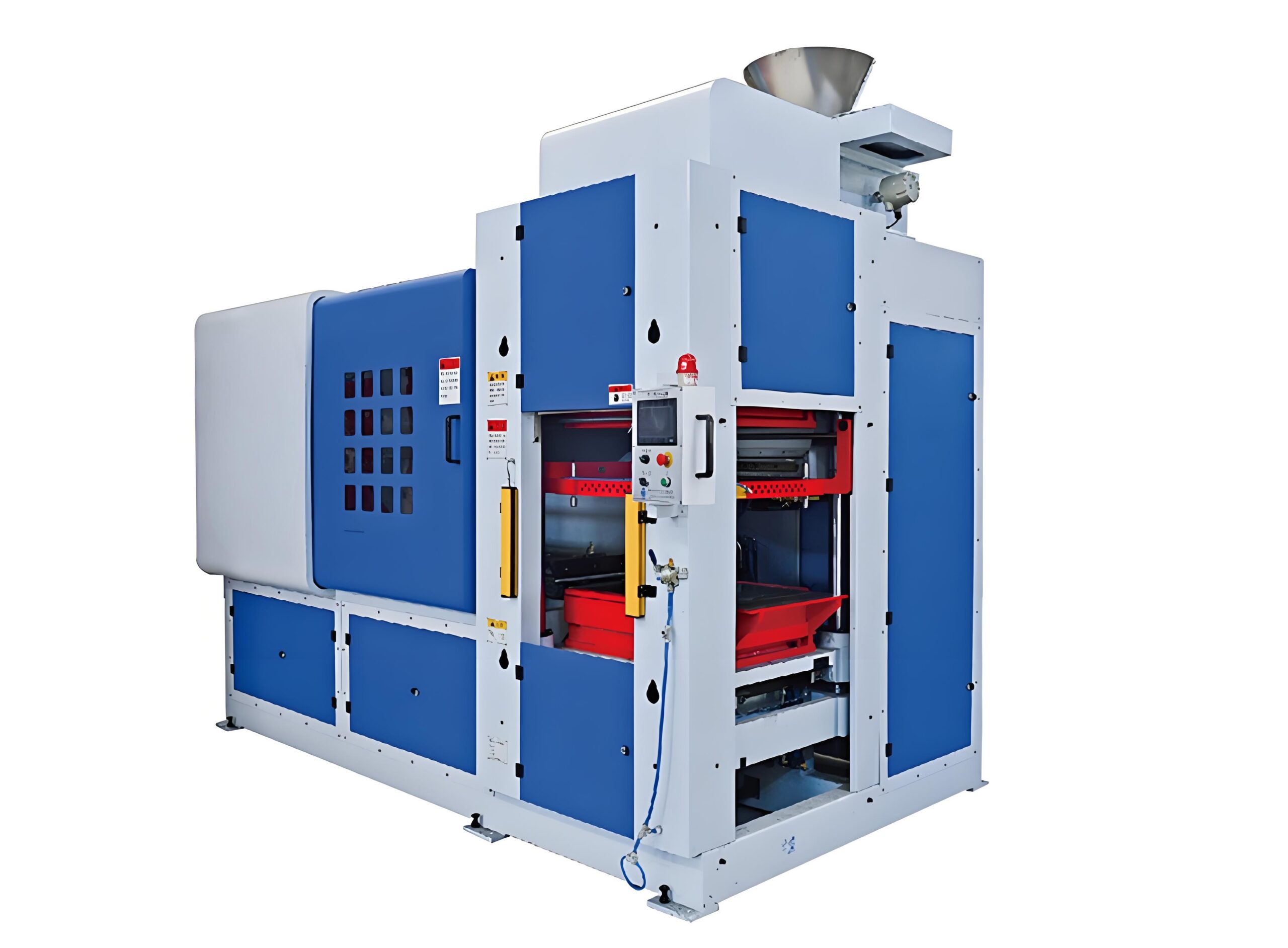

Automatic Horizontal Flaskless Molding Machine

Automatic Horizontal Flaskless Molding Machine

Efficiency and Speed:

Flaskless molding machines can produce molds at a much faster rate compared to traditional flask-based systems.

Automated mold handling reduces the cycle time and increases production rates.

Consistency and Quality:

High repeatability ensures consistent mold quality, which is essential for producing parts with tight tolerances.

Improved dimensional accuracy and surface finish reduce the need for secondary machining.

Reduced Labor Costs:

Automation of the molding process reduces the reliance on manual labor, leading to lower labor costs.

Less manual intervention also means fewer opportunities for human error.

Product Parameters

Applications

- Automotive Industry:

- Production of engine blocks, cylinder heads, and other complex automotive components.

- High precision and repeatability are crucial for these parts, and flaskless molding machines provide that consistency.

- Aerospace Industry:

- Manufacturing of intricate parts that require high dimensional accuracy and excellent surface finish.

- Components such as turbine blades, housings, and other critical parts.

- Industrial Machinery:

- Casting of components for heavy machinery, pumps, compressors, and other industrial equipment.

- These parts often require robust, durable molds which flaskless machines can produce efficiently.

- Consumer Goods:

- Production of parts for household appliances, tools, and hardware.

- Flaskless molding allows for high-volume production with minimal defects.

- Construction Industry:

- Casting of components like valves, fittings, and other plumbing and infrastructure-related parts.

Main Benefits

Efficiency and Speed:

Flaskless molding machines can produce molds at a much faster rate compared to traditional flask-based systems.

Automated mold handling reduces the cycle time and increases production rates.

Consistency and Quality:

High repeatability ensures consistent mold quality, which is essential for producing parts with tight tolerances.

Improved dimensional accuracy and surface finish reduce the need for secondary machining.

Reduced Labor Costs:

Automation of the molding process reduces the reliance on manual labor, leading to lower labor costs.

Less manual intervention also means fewer opportunities for human error.

Material Savings:

Optimized mold design and efficient use of sand reduce material wastage.

Flaskless molding machines often have mechanisms to reclaim and reuse sand, further reducing costs.

Flexibility:

Capable of producing a wide range of part sizes and shapes without the need for different flasks for each mold.

Quick changeovers between different mold patterns enhance production flexibility.

Environmental Benefits:

Reduced sand wastage and the potential for sand reclamation contribute to more sustainable production practices.

Lower energy consumption compared to traditional molding methods.

Model & Specification

| No. | Items | CHJ5060 | CHJ6070 | CHJ8090 | CHJ9010 |

| 1 | Mold dimensions | 500×600mm | 600×700mm | 800x900mm | 900x1000mm |

| 2 | Thickness of sand box | Up:120-220mm Down:120-220mm | Up:120-220mm Down:120-220mm | Up:180-340mm Down:180-340mm | Up:190-360mm Down:190-360mm |

| 3 | Molding speed | 32s/mold (without the time for sand core loading) | 36s/mold (without the time for sand core loading) | 52s/mold (without the time for sand core loading) | 65s/mold (without the time for sand core loading) |

| 4 | Squeeze pressure | ≤25Mpa | ≤25Mpa | ≤25Mpa | ≤25Mpa |

| 5 | Air consumption | 3.5³(Normal) | 6. 0³(Normal) | 6. 0³(Normal) | 8. 0³(Normal) |

| 6 | Control method | PLC automatic control | PLC automatic control | PLC automatic control | PLC automatic control |

| 7 | Drive method | Electric-pneumatic-hydraulic | Electric-pneumatic-hydraulic | Electric-pneumatic-hydraulic | Electric-pneumatic-hydraulic |

| 8 | Template thickness | 30mm | 30mm | 35mm | 35mm |

| 9 | Power supply | AC380V,50Hz | AC380V,50Hz | AC380V,50Hz | AC380V,50Hz |

| 10 | Sprue quantity | 25 pcs | 40 pcs | 9 pcs | 9 pcs |

| 11 | Sprue diameter | 25mm | 25mm | 35mm | 35mm |

| 12 | External dimensions | 3300×1800×2900mm | 3500*2000*3500mm | 5146*3610*4450mm | 5542*3106*4656mm |

We have more models and types of automatic flaskless molding machine, you can contact and get the Contact Professional Engineer.

Feature

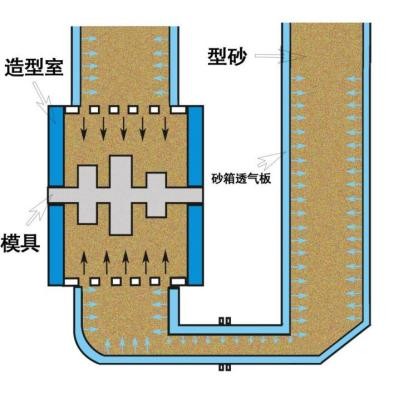

- Top shot and bottom shot sand shooting method;

- Uniform filling density of the molding sand;

- Suitable for the more complex casting molding;

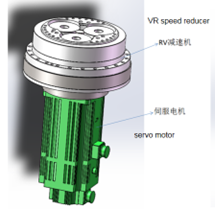

- Servo motor

- Precision control

- Smooth movement

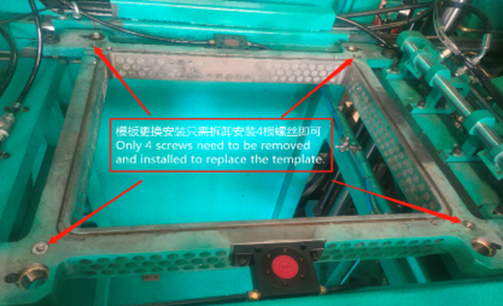

- Durable material;

- Easy installation;

- Rexroth brand

- Control system