Wind turbine base deformation during shot blast causes installation failures; scientific measures ensure stable shot blasting quality.

This guide details key methods to prevent wind turbine base deformation during shot blasting, optimizing shot blaster use and machine shot control for safe, efficient operations.

Explore core prevention measures and operation tips for shot blast deformation below.

Why Is Deformation Prevention Critical for Wind Turbine Bases During Shot Blasting?

Wind turbine bases are large, heavy-duty steel structures that bear the entire weight of wind turbines, requiring extremely high dimensional accuracy and structural stability. Shot blasting is a vital surface treatment process for wind turbine bases—removing rust, oxide scales, and welding residues to enhance anti-corrosion performance and ensure coating adhesion.

- However, improper shot blast operations often cause base deformation, which leads to severe consequences: deformed bases cannot be accurately installed with wind turbine towers, resulting in rework, delayed construction periods, and increased costs; uneven stress caused by deformation reduces the base’s load-bearing capacity, posing potential safety hazards for wind turbine operation (such as tower tilting or collapse in harsh wind conditions);

- Excessive deformation may even render the base unusable, causing direct economic losses. Unlike small workpieces, wind turbine bases are difficult to correct after deformation, making prevention the key to shot blasting operations. Scientific deformation prevention measures not only ensure the dimensional accuracy of the base but also maintain the stability of shot blasting quality, extending the service life of wind turbine bases and ensuring safe, long-term operation of wind power projects.

For wind power manufacturers and construction enterprises, mastering deformation prevention methods during shot blasting is essential to improve production efficiency and project quality.

How to Select Suitable Shot Blasters and Machine Shot for Wind Turbine Base Shot Blasting?

Selecting the right shot blasters and machine shot is the foundation of preventing wind turbine base deformation during shot blasting, as improper equipment and abrasive selection directly lead to uneven shot blast force and localized stress concentration.

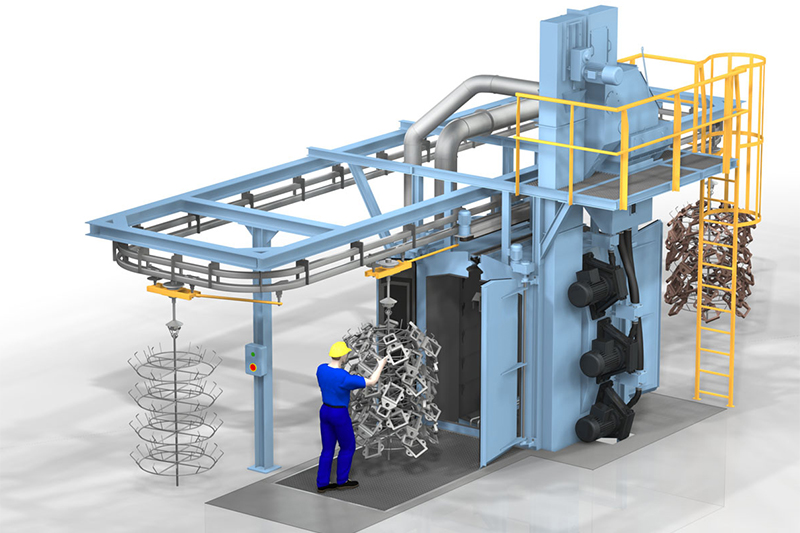

- Choose the appropriate shot blaster type: wind turbine bases are large, flat steel structures, so gantry-type or overhead rail shot blasters are preferred—these shot blasters can achieve uniform shot blast coverage across the entire base surface, avoiding localized excessive shot blast that causes deformation. Avoid using small, fixed shot blasters that can only treat partial areas, as they easily create uneven stress.

- Optimize shot blaster parameters: select shot blasters with adjustable impeller speed, machine shot flow rate, and shot blast pressure, enabling precise control of shot blast intensity. For wind turbine bases (usually made of Q345 steel), set the impeller speed to 1500-1800rpm, machine shot flow rate to 200-250kg/min, and shot blast pressure to 0.6-0.7MPa—this ensures thorough surface cleaning without excessive impact force.

- Choose suitable machine shot: use spherical steel shot with uniform particle size (1.0-1.5mm) and moderate hardness (HRC 40-50). Avoid using angular or oversized machine shot, which generates excessive local impact force and causes deformation; also avoid undersized machine shot, which requires increased shot blast time and intensity, leading to cumulative stress and deformation. High-quality machine shot ensures uniform impact force during shot blasting, reducing the risk of base deformation.

How to Optimize Shot Blasting Process Parameters to Prevent Wind Turbine Base Deformation?

Optimizing shot blasting process parameters is the core of preventing wind turbine base deformation, as improper parameter settings (such as excessive shot blast intensity, uneven coverage, or unreasonable shot blast angle) are the main causes of deformation.

- Control shot blast intensity and time: excessive shot blast intensity or prolonged shot blast time will generate cumulative stress on the base surface, leading to plastic deformation. Conduct pre-shot blast tests on base samples to determine the optimal shot blast time (usually 8-12 minutes per square meter) and intensity, ensuring thorough cleaning while minimizing stress.

- Ensure uniform shot blast coverage: adjust the shot blaster’s nozzle angle (45-60° relative to the base surface) and moving speed (0.5-1m/min) to ensure every area of the base is shot blasted uniformly. Avoid overlapping shot blast areas excessively (no more than 20%) to prevent localized stress concentration. For large bases, divide the surface into multiple zones and shot blast each zone sequentially, ensuring consistent parameters across all zones.

- Optimize shot blast sequence: start shot blasting from the center of the base and move outward, or from the edges to the center—this distributes stress evenly and reduces deformation. Avoid shot blasting only one side of the base first; instead, alternate between opposite sides to balance stress.

- Control machine shot temperature: in low-temperature environments, cold machine shot can increase the brittleness of the base material, making it more prone to deformation. Preheat machine shot to 15-25℃ before use to reduce temperature-induced stress. These parameter optimizations effectively distribute shot blast stress, preventing wind turbine base deformation.

How to Use Fixtures and Support Structures to Prevent Deformation During Shot Blasting?

Wind turbine bases are large, thin-walled (relative to their size) structures that are prone to deformation under their own weight or shot blast impact—using reasonable fixtures and support structures can effectively disperse stress and maintain dimensional accuracy during shot blasting.

- Design customized support structures: according to the base’s shape and size, use adjustable steel supports or cushion blocks to support the base at multiple points (every 1.5-2m along the length and width). Ensure the supports are placed at the base’s stiffening ribs or load-bearing points to avoid local pressure concentration and deformation. The support height should be consistent to keep the base in a horizontal position, preventing deformation caused by uneven self-weight.

- Use positioning fixtures to fix the base: install adjustable fixtures around the base to limit its movement during shot blasting. The fixtures should be flexible enough to avoid restricting the base’s thermal expansion and contraction during shot blasting (which can cause internal stress), but firm enough to prevent displacement under shot blast impact. Avoid clamping the base too tightly, as this can generate additional stress and deformation.

- Add temporary stiffeners for thin-walled areas: for thin-walled parts of the base (such as flange edges), install temporary steel stiffeners before shot blasting to enhance structural rigidity and resist shot blast-induced deformation. Remove the stiffeners after shot blasting and touch up the shot blast areas if necessary.

- Inspect and adjust supports and fixtures regularly: during shot blasting, periodically check the supports and fixtures for looseness or displacement, and adjust them promptly to ensure the base remains stable. These fixture and support measures effectively disperse stress, prevent displacement, and maintain the base’s dimensional accuracy during shot blasting.

How to Conduct Post-Shot Blasting Inspection and Deformation Correction (If Necessary)?

Even with strict prevention measures, minor deformation may occur during wind turbine base shot blasting—conducting timely post-shot blasting inspection and targeted correction is essential to ensure base quality.

- Establish a comprehensive inspection process: after shot blasting, cool the base to room temperature (to avoid temperature-induced measurement errors) and use professional measuring tools (such as total stations, level gauges, and straightedges) to inspect the base’s flatness, parallelism, and dimensional accuracy. Focus on key areas such as flange surfaces, bolt holes, and stiffening ribs—these areas have strict accuracy requirements for wind turbine installation. Compare the measurement results with design standards; if deformation exceeds the allowable range (usually ±2mm per meter), take correction measures immediately.

- Adopt appropriate correction methods: for minor deformation (within 3mm), use heat correction (local heating of the deformed area to 600-700℃, followed by slow cooling) to eliminate stress and restore dimensional accuracy. Avoid overheating, as this can damage the base’s material properties. For moderate deformation (3-5mm), use mechanical correction (such as hydraulic jacks or press machines) to gently push the deformed area back to the design position, ensuring uniform force to avoid secondary deformation. For severe deformation (exceeding 5mm), it may be necessary to cut and re-weld the deformed area, followed by re-shot blasting.

- Re-inspect after correction: after correction, conduct a second shot blasting on the corrected area to ensure surface quality, then re-measure to confirm the base meets design standards.

- Record inspection and correction data: keep detailed records of shot blasting parameters, inspection results, and correction measures—this helps summarize experience, optimize prevention measures, and avoid repeated deformation problems. Post-shot blasting inspection and correction ensure that only qualified wind turbine bases enter the next installation process.

Conclusion

Proper shot blaster use, parameter control and support prevent wind base deformation.

For professional advice on wind turbine base shot blasting and deformation prevention,

contact us via email: [email protected]