Suboptimal shot blasting for automotive parts causes quality flaws; process optimization with Wheelblast Equipment ensures consistency and efficiency.

This guide details practical methods to optimize the shot blasting process for automotive parts, leveraging Wheelblast Equipment and shot blasting machines to enhance quality, reduce costs, and boost productivity.

Explore key optimization strategies and precautions for automotive parts shot blast below.

Why Is Shot Blasting Process Optimization Critical for Automotive Parts?

Shot blasting is a vital process in automotive parts manufacturing, as it directly impacts the quality, performance, and service life of components such as engine blocks, gears, chassis parts, and body panels.

- Suboptimal shot blast processes lead to a range of issues: uneven surface roughness affects subsequent coating adhesion, leaving parts vulnerable to corrosion; incomplete removal of burrs, sand, or rust leads to assembly failures and premature wear; excessive machine shot causes surface damage, increasing rework rates and material waste. These flaws not only raise production costs but also pose safety risks for automotive operation.

- Process optimization addresses these pain points by maximizing the efficiency of Wheelblast Equipment and shot blasting machines, ensuring consistent surface quality, reducing rework and downtime, and aligning with strict automotive industry standards.

Additionally, optimized shot blasting enhances the fatigue resistance of critical parts, extending the overall service life of vehicles. In summary, shot blasting process optimization is essential for balancing quality, efficiency, and cost in automotive parts production.

How to Select Suitable Wheelblast Equipment and Shot Blasting Machines for Automotive Parts?

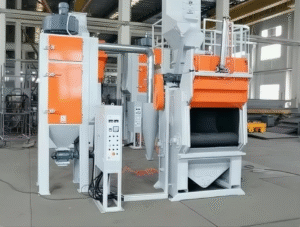

Selecting the right Wheelblast Equipment and shot blasting machines is the foundation of process optimization, as different automotive parts require specialized equipment to achieve optimal shot blast results.

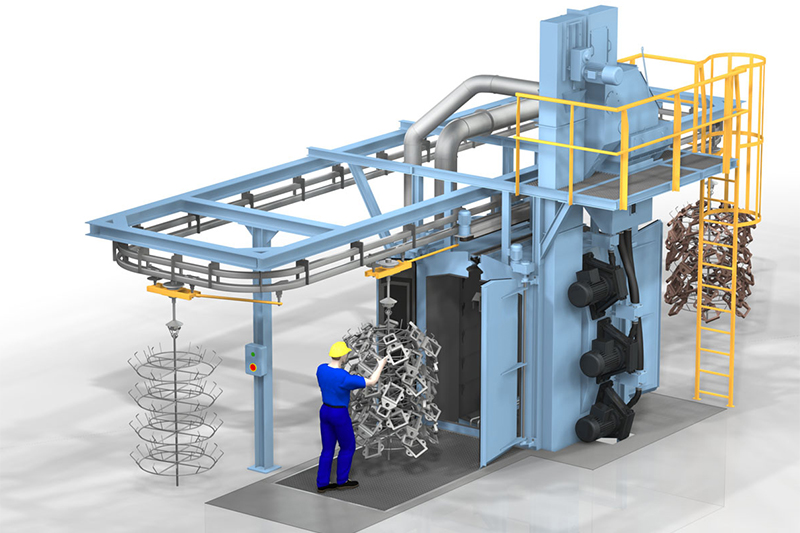

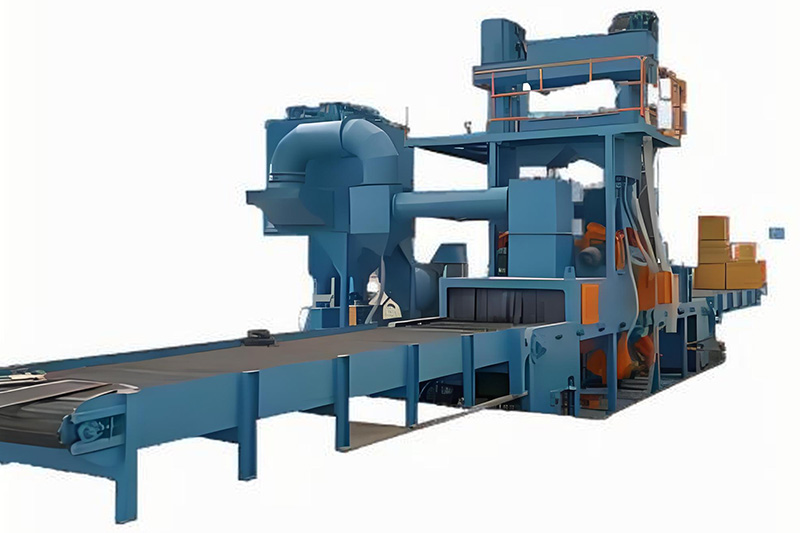

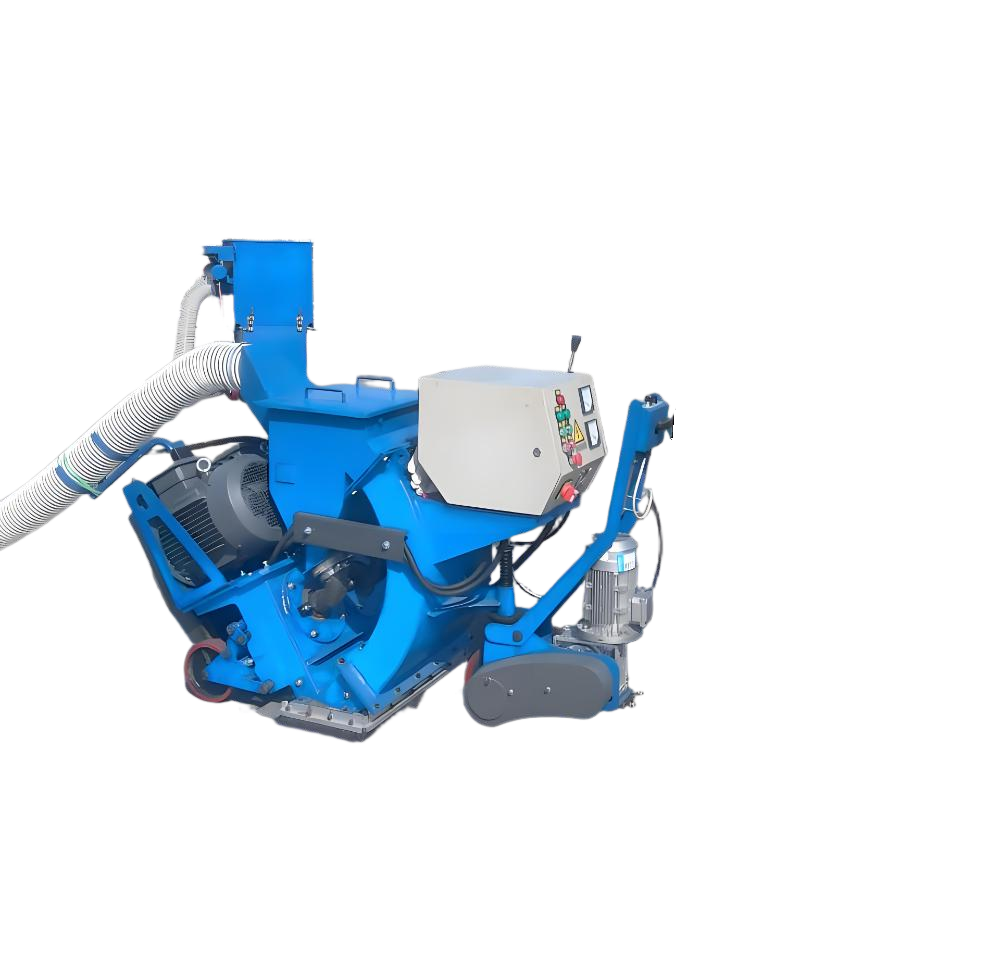

- Match equipment type to part characteristics: for small, precision parts (such as bolts, nuts, and small gears), use tumble belt shot blasting machines, which ensure uniform machine shot by tumbling parts continuously. For large, heavy parts (such as engine blocks, chassis frames), choose table-type or overhead rail Wheelblast Equipment, which allows for precise positioning and targeted shot blast. For sheet metal parts (such as body panels), opt for air blast shot blasting machines to avoid surface deformation.

- Prioritize equipment with adjustable parameters: select Wheelblast Equipment equipped with variable frequency drives (VFDs) to control impeller speed, abrasive flow rate, and shot blast pressure, enabling flexibility for different part requirements.

- Ensure compatibility with automotive standards: choose shot blasting machines with high precision and stability, capable of achieving consistent surface roughness (Ra 1.6-6.3μm) as required by automotive manufacturers. Investing in suitable Wheelblast Equipment not only improves shot blast quality but also reduces energy consumption and equipment wear, laying a solid foundation for process optimization.

How to Optimize Machine Shot Parameters for Different Automotive Parts?

Machine shot parameters are the core of shot blasting process optimization, and adjusting them according to the type, material, and size of automotive parts ensures optimal results.

- Optimize parameters for ferrous metal parts (such as steel gears, engine blocks): use Wheelblast Equipment with an impeller speed of 1600-1900rpm, abrasive flow rate of 220-280kg/min, and shot blast distance of 60-80mm. Select spherical steel shot with a particle size of 0.8-1.5mm to achieve moderate surface roughness and thorough derusting.

- Adjust parameters for non-ferrous metal parts (such as aluminum alloy body panels): reduce impeller speed to 1200-1500rpm, flow rate to 150-200kg/min, and increase shot blast distance to 80-100mm. Use fine glass beads or aluminum oxide (0.3-0.8mm) to avoid surface scratches and deformation.

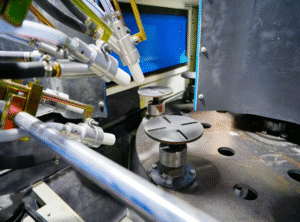

- Optimize parameters for precision parts (such as transmission gears): maintain a low shot blast pressure (0.5-0.7MPa), uniform abrasive flow, and a 45-60° shot blast angle to ensure consistent surface texture without damaging tooth profiles.

- Conduct test runs and parameter calibration: before formal production, perform trial shot blasting on sample parts, measure surface roughness and cleanliness, and adjust parameters accordingly. Establish a parameter database for different automotive parts to enable quick adjustment during mass production, ensuring consistency and efficiency.

How to Optimize Abrasive Selection and Management for Automotive Parts Shot Blasting?

Abrasive selection and management directly affect shot blast quality and Wheelblast Equipment performance, making them key to process optimization.

- Select abrasives based on part material and requirements: for automotive parts requiring high surface finish (such as body panels), use spherical abrasives (steel shot, glass beads) for uniform impact and smooth surfaces. For parts needing thorough derusting or deburring (such as chassis parts), use angular abrasives (steel grit) to enhance cleaning efficiency. Ensure abrasive hardness matches the part material—abrasive hardness should be 10-20% higher than the part’s hardness to avoid excessive wear or insufficient cleaning.

- Control abrasive quality: use abrasives with uniform particle size (error within ±0.2mm) and avoid mixed or contaminated abrasives, which cause uneven surface quality and clog Wheelblast Equipment pipelines. Filter abrasives before adding them to the shot blasting machine to remove debris and worn particles.

- Optimize abrasive recovery and reuse: equip shot blasting machines with efficient abrasive recovery systems to recycle 80-90% of usable abrasives, reducing material costs. Regularly inspect the recovery system, clean pipelines and separators, and replace worn screens to ensure smooth operation.

- Monitor abrasive wear: replace abrasives when their particle size is reduced by more than 30%, as worn abrasives reduce cleaning efficiency and increase equipment wear. Proper abrasive selection and management can reduce material waste by 40%, improve shot blast quality, and extend the service life of Wheelblast Equipment.

How to Optimize Process Flow and Quality Control for Automotive Parts Shot Blasting?

Optimizing the overall process flow and strengthening quality control ensures stable, consistent results from the shot blasting process for automotive parts.

- Optimize pre-shot blast preparation: clean automotive parts to remove oil, grease, and loose contaminants before shot blast, as these substances reduce abrasive adhesion and affect cleaning efficiency. Use degreasing agents or high-pressure air to ensure part surfaces are clean and dry. Arrange parts in the Wheelblast Equipment to avoid overlapping or shielding, ensuring all surfaces are fully exposed to machine shot. For complex-shaped parts (such as engine cylinder heads), use rotating fixtures to achieve uniform shot blast coverage.

- Optimize post-shot blast treatment: after shot blasting, use compressed air to blow off residual abrasives and dust from part surfaces, ensuring no debris remains. Conduct visual inspections and surface roughness testing to check for defects such as uneven surfaces, scratches, or incomplete cleaning.

- Establish strict quality control standards: set clear criteria for surface roughness, cleanliness, and burr removal, and use professional tools (roughness testers, cleanliness meters) to inspect parts regularly. Implement statistical process control (SPC) to monitor process stability, identify deviations early, and adjust parameters or equipment promptly.

- Optimize production scheduling: coordinate the shot blasting process with upstream (casting, forging) and downstream (coating, assembly) processes to reduce downtime and improve production efficiency. Train operators to master process requirements and quality control skills, ensuring consistent operation. These optimizations reduce rework rates by 35% and ensure automotive parts meet strict industry standards.

Conclusion

Equipment selection, parameter adjustment and process control optimize automotive parts shot blasting.

For professional guidance on automotive parts shot blasting optimization and Wheelblast Equipment selection,

contact us via email: [email protected]