Choosing the wrong shot blasting machine leads to poor cleaning, wasted costs, and delays. This guide simplifies Shot Blasting Machine Selection for optimal results.

This guide covers key factors, Machine Type Matching, Core Performance comparison, critical Selection Parameters, common Selection Pitfalls, and cost-quality balance for effective shot blasting machine choices.

Dive into detailed insights below to pick the perfect machine for your needs.

What are the key factors determining shot blasting machine suitability?

Shot blasting machine suitability hinges on four core factors that directly impact cleaning outcomes: workpiece characteristics, production demands, site conditions, and industry standards. Workpiece details—size, weight, material, and surface contamination level—are foundational. For example, delicate aluminum parts require gentler shot intensity than heavy steel castings. Production demands, including batch size and processing speed, dictate whether a continuous or batch-type machine is ideal; high-volume lines need through-type models, while small workshops thrive with tumblast machines. Site constraints such as floor space, ceiling height, and power supply limit options—hook-type machines need ample vertical space, while compact track-type models suit tight areas. Industry standards, especially environmental regulations, mandate dust and noise control features, ensuring compliance to avoid penalties. These factors intersect to define the most suitable machine, making them the starting point of any successful Shot Blasting Machine Selection.

Which shot blasting machine type fits your workpiece and production needs?

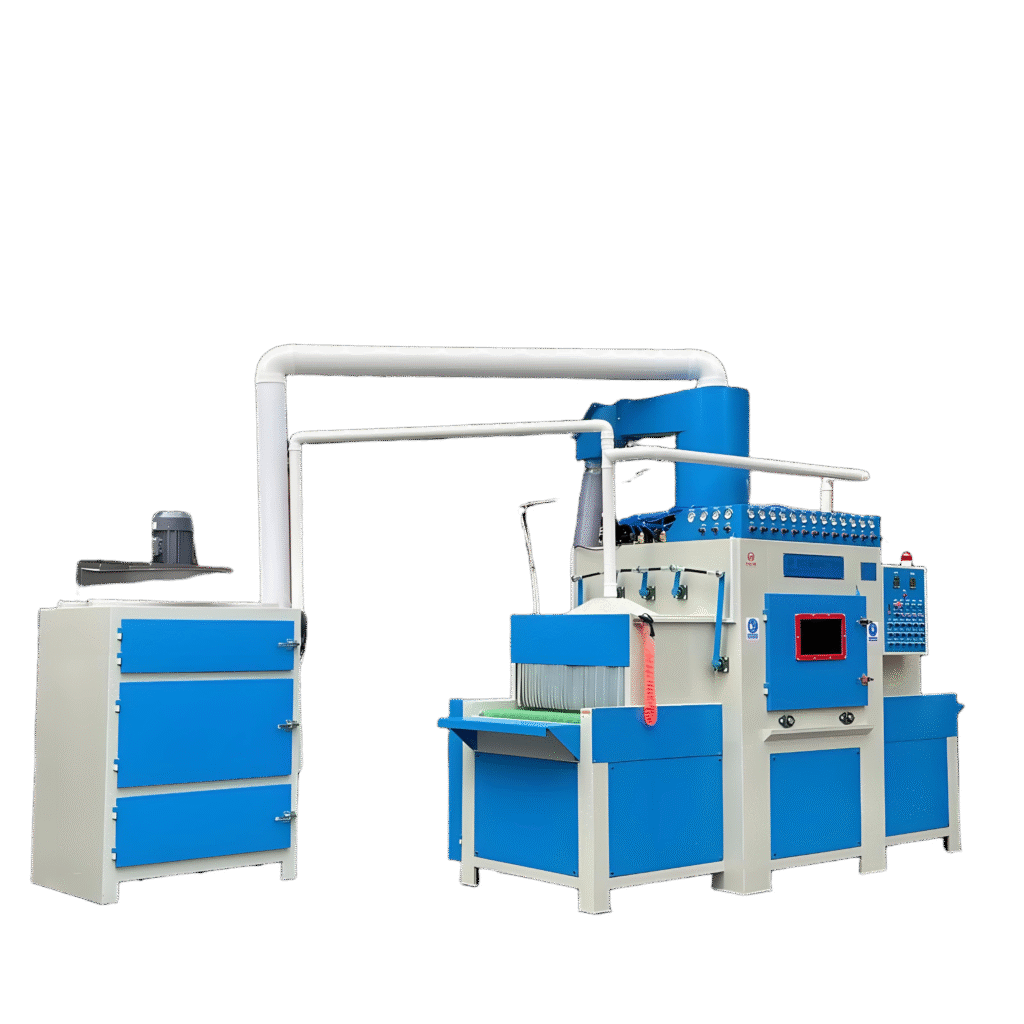

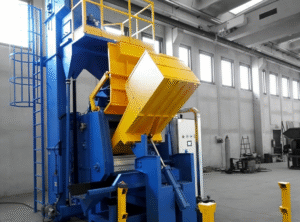

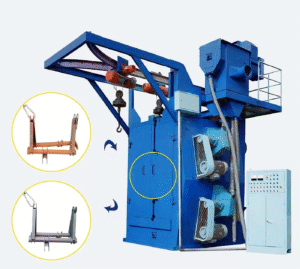

Machine Type Matching is critical to aligning equipment with workpiece and production requirements. Tumblast machines excel for small, bulk workpieces like screws or gears—their rotating drum tumbles parts for uniform cleaning, ideal for low-to-medium volume production. Track-type machines handle medium-sized parts (e.g., auto components, castings) with a conveyor track, balancing efficiency and versatility for batch or continuous operations. Hook-type machines are perfect for large, heavy workpieces such as steel beams or engine blocks; their suspended hooks rotate parts 360°, ensuring no cleaning dead ends, suited for high-precision, low-volume production. Through-type machines cater to long workpieces like profiles or plates, enabling continuous processing for high-volume assembly lines. Assessing your workpiece’s size, weight, and production volume directly leads to the right type, avoiding mismatches that cause inefficiency.

How to compare core performance for optimal cleaning efficiency?

Evaluating Core Performance is essential to ensure optimal cleaning efficiency. Key metrics include shot blasting rate (kg/min), surface cleanliness (Sa level), energy consumption (kW/h), and durability. Shot blasting rate determines how quickly parts are processed—higher rates suit high-volume needs but may increase energy use. Surface cleanliness, measured by Sa standards (Sa2.5 for general industrial use, Sa3 for precision applications), ensures parts meet quality requirements. Energy consumption impacts operational costs; modern energy-efficient models reduce long-term expenses without sacrificing performance. Durability, reflected in wear-resistant components like manganese steel liners or high-chromium blades, minimizes downtime and maintenance costs. Comparing these metrics across models helps identify a machine that delivers consistent, efficient cleaning while aligning with your performance priorities.

What parameters should not be ignored when selecting a shot blasting machine?

Overlooking critical Selection Parameters leads to costly mistakes. Shot size and type (steel shot, grit, or glass beads) must match workpiece material—harder materials need larger, denser shot, while soft materials require finer, lighter options. Chamber size must accommodate the maximum workpiece dimensions, with extra space for shot circulation. Dust collection efficiency (minimum 99% separation rate) ensures environmental compliance and worker safety. Abrasive recycling systems reduce material waste and costs, so check for efficient separators and storage capacity. Control systems, from manual to PLC automation, impact ease of use and consistency—automated systems suit high-volume, precision-focused operations. Additionally, noise levels (ideally below 85dB) and maintenance access (e.g., removable liners) affect workplace safety and upkeep. These parameters directly influence performance, cost, and compliance, making them non-negotiable in selection.

What common mistakes ruin shot blasting machine selection?

Awareness of Selection Pitfalls prevents costly errors. One major mistake is prioritizing initial price over total cost of ownership—cheap machines often have inferior components, leading to frequent breakdowns and high maintenance costs. Another error is mismatching machine capacity to production needs: overestimating leads to idle equipment, while underestimating causes bottlenecks. Ignoring workpiece material compatibility results in surface damage or inadequate cleaning—e.g., using steel shot on aluminum parts scratches surfaces. Neglecting environmental compliance risks fines and production halts; ensure the machine meets local dust and noise regulations. Forgetting after-sales support leaves you stranded with broken equipment; choose manufacturers with reliable service and spare parts availability. Avoiding these pitfalls ensures a selection that delivers long-term value.

How to balance cost and cleaning quality in selection?

Balancing cost and cleaning quality requires a strategic approach to Shot Blasting Machine Selection. Start by defining minimum quality requirements (e.g., Sa2.5 cleanliness) to avoid overpaying for unnecessary precision. Compare total cost of ownership, including purchase price, energy use, abrasive replacement, and maintenance, rather than just upfront cost. Energy-efficient models may have higher initial prices but lower monthly bills. Opt for machines with universal, readily available spare parts to reduce maintenance costs. Consider scalable options that grow with your production needs, avoiding premature replacement. Additionally, prioritize manufacturers offering warranties and technical support to minimize unexpected expenses. By weighing quality needs against long-term costs, you achieve a cost-effective solution that doesn’t compromise cleaning performance.

Conclusion

Follow this guide to select the right shot blasting machine for efficient, high-quality cleaning.