Many people confuse shot blasting machines; lack of understanding leads to wrong selection and inefficient use.

This article explains what a shot blasting machine is, details its working principle, and focuses on its core uses to help you fully understand shot blasting and machine shot.

Read on to clarify doubts about shot blasting machines and their practical applications.

What Is a Shot Blasting Machine and How Does It Work?

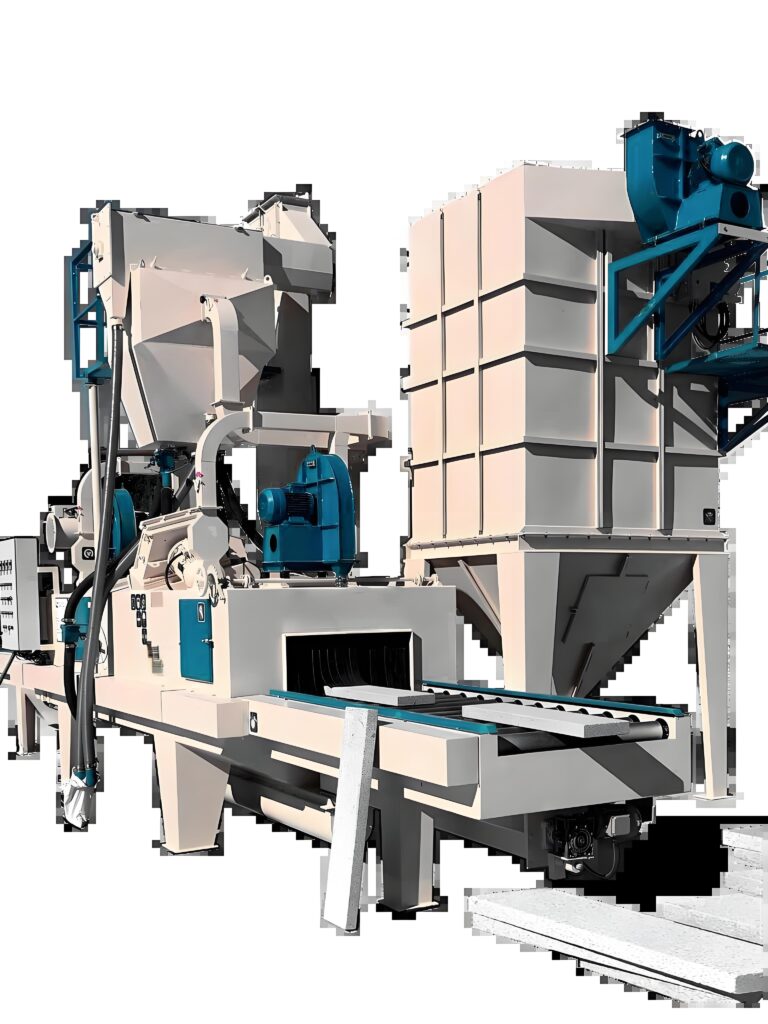

A shot blasting machine is a professional industrial equipment designed to clean, strengthen, or polish workpiece surfaces through shot blasting—a process that uses high-speed abrasive projectiles (known as machine shot) to impact the workpiece surface. Its working principle is simple yet efficient:

- First, the shot blasting machine’s impeller (the core component) rotates at high speed, generating centrifugal force to accelerate machine shot to a speed of 50-80m/s.

- Then, the accelerated machine shot is sprayed onto the workpiece surface uniformly through a directional sleeve and nozzle. The impact force of the machine shot removes burrs, rust, oxide scales, and contaminants from the workpiece surface, while also forming a certain roughness to improve the adhesion of subsequent coatings.

- Unlike manual cleaning or chemical treatment, shot blasting is environmentally friendly, efficient, and non-damaging to the workpiece base material. A high-quality shot blasting machine can achieve continuous and uniform shot blasting, ensuring consistent surface treatment effects for batches of workpieces, which is why it is widely used in various industries.

What Are the Core Industrial Uses of Shot Blasting Machines?

Shot blasting machines have a wide range of core uses, covering multiple industrial fields, with three main application scenarios that highlight their value.

- Surface cleaning: this is the most common use of shot blasting machines. In the automotive, construction, and casting industries, workpieces (such as castings, steel structures, and automotive parts) often have rust, oxide scales, or sand residues on their surfaces after production. Shot blasting can quickly and thoroughly remove these contaminants, preparing for subsequent processes such as painting, electroplating, and assembly.

- Surface strengthening: shot blasting machines can enhance the fatigue resistance of workpieces through machine shot impact. When high-speed machine shot hits the workpiece surface, it forms a compressive stress layer on the surface, which can effectively prevent the generation and expansion of cracks, extending the service life of critical parts (such as gears, springs, and chassis components).

- Surface finishing: in the hardware and precision manufacturing industries, shot blasting machines can polish the workpiece surface to achieve a smooth or matte finish, improving the appearance quality of products. For example, hardware accessories can be made more delicate and wear-resistant through shot blasting, while precision components can achieve the required surface roughness through controlled shot blasting.

What Are the Common Types of Shot Blasting Machines and Their Applicable Scenarios?

Different types of shot blasting machines are designed for different workpieces and shot blasting needs, and understanding their differences helps to select the right equipment.

- The first common type is the tumble shot blasting machine, which is suitable for small and medium-sized workpieces (such as bolts, nuts, and small gears). Workpieces are placed in a rotating drum, and machine shot is sprayed into the drum to achieve uniform shot blasting through the tumbling of the drum.

- The second type is the table-type shot blasting machine, which is suitable for large, heavy, or irregularly shaped workpieces (such as engine blocks, large castings, and steel plates). The workpiece is fixed on a rotatable table, and the shot blasting nozzle moves to complete comprehensive shot blasting.

- The third type is the continuous shot blasting machine, which is suitable for mass production lines (such as automotive parts assembly lines). It can realize continuous feeding, shot blasting, and discharging, greatly improving shot blasting efficiency.

No matter which type, the core function is to complete efficient and high-quality shot blasting through scientific machine shot control, meeting the diverse needs of different industries.

Conclusion

Shot blasting machines realize efficient surface treatment with diverse core uses.

For professional advice on shot blasting machines and shot blasting solutions,

contact us via email:[email protected]