Many confuse shot blasting machines with sand blasting; wrong selection causes inefficiency and quality flaws.

This guide clearly distinguishes between shot blasting machines and sand blasting, detailing their working principles, differences, and application scenarios to avoid confusion.

Explore key differences and selection tips to tell them apart easily below.

What Is the Core Working Principle of a Shot Blasting Machine vs Sand Blasting?

The fundamental difference between a shot blasting machine and sand blasting lies in their working principles and power sources, which directly determine their application scope.

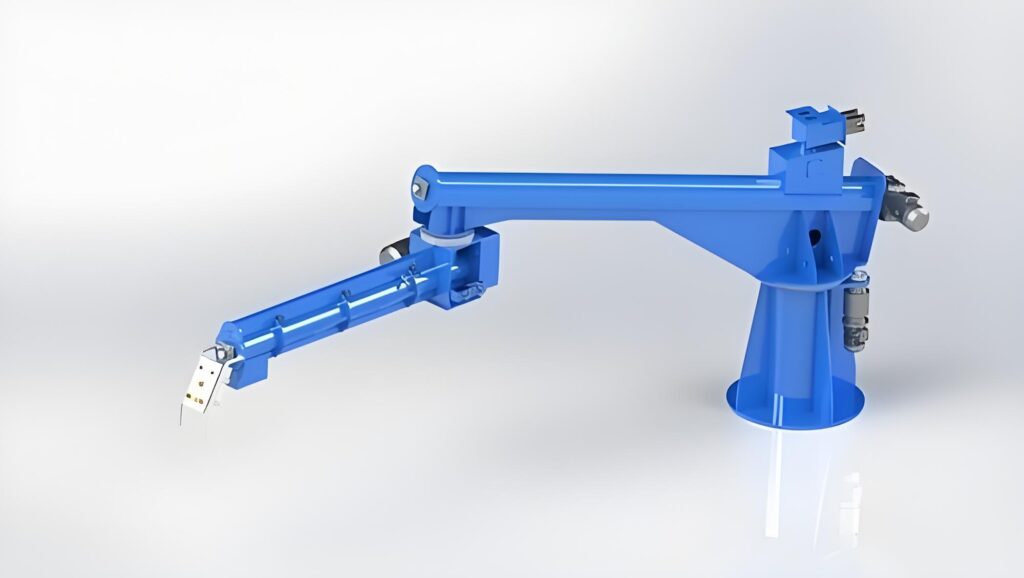

- A shot blasting machine is a fully automated or semi-automated piece of equipment that uses centrifugal force (generated by a high-speed rotating impeller) to accelerate abrasive (usually steel shot, known as machine shot) to high speeds, impacting the workpiece surface to achieve cleaning, strengthening, or finishing. It does not require compressed air, relying instead on the machine’s internal power to drive the abrasive, making it more efficient for large-batch, large-workpiece processing.

- In contrast, sand blasting (often performed with a sand blasting machine) uses compressed air to spray abrasive (such as quartz sand, corundum) onto the workpiece surface. It is more flexible, suitable for small workpieces, precision parts, or on-site operations, but relies on air pressure and is relatively less efficient than a shot blasting machine.

Additionally, a shot blasting machine recycles abrasive automatically, while sand blasting often generates more waste abrasive, increasing material costs over time.

What Are the Key Differences in Abrasive Selection Between Shot Blasting Machines and Sand Blasting?

Abrasive selection is another critical distinction between a shot blasting machine and sand blasting, as each uses different types of abrasives that match their working principles and processing needs.

- A shot blasting machine primarily uses metal abrasives, with spherical steel shot being the most common—its round shape ensures uniform impact, avoiding excessive damage to the workpiece surface while achieving surface strengthening. Other common abrasives for shot blasting machines include steel grit (for heavy-duty cleaning) and stainless steel shot (for rust-free finishing).

- These abrasives are reusable, which aligns with the shot blasting machine’s automatic recycling system, reducing waste. On the other hand, sand blasting (and sand blasting machines) mainly uses non-metallic abrasives, such as quartz sand, river sand, and corundum. These abrasives are harder and more angular, making them ideal for removing heavy rust, thick oxide scales, or old coatings, but they are usually single-use and generate more dust. The abrasive difference also means a shot blasting machine is more suitable for surface strengthening, while sand blasting excels at aggressive cleaning.

How to Choose Between a Shot Blasting Machine and Sand Blasting for Different Scenarios?

Choosing between a shot blasting machine and sand blasting depends on your processing needs, workpiece characteristics, and production scale, and clarifying these factors avoids wrong selection.

- For large-scale mass production (such as automotive parts, steel structures), a shot blasting machine is the better choice—it is efficient, automated, and ensures consistent processing quality, while its abrasive recycling system reduces long-term costs. It is also ideal for workpieces requiring surface strengthening (such as gears, springs), as the metal abrasive’s impact forms a compressive stress layer.

- For small-batch processing, precision parts (such as electronic components, medical devices), or on-site operations (such as ship maintenance), sand blasting (with a sand blasting machine) is more suitable—its flexibility allows for targeted processing, and non-metallic abrasives avoid surface damage.

Additionally, if you need aggressive cleaning (such as removing thick rust from old steel structures), sand blasting is more effective; if you prioritize efficiency, automation, and surface quality consistency, a shot blasting machine is the optimal option.

Conclusion

Distinguish them by principle, abrasive and scenario; choose the right one.

For advice on shot blasting machines, sand blasting machines and selection,

contact us via email: [email protected]