Shot blasting machine inefficiency wastes time and increases costs; 3 simple tricks quickly boost shot blasting efficiency.

This guide shares 3 practical tricks to quickly improve shot blasting machine efficiency, optimizing machine shot use and shot blasting processes for cost savings.

Learn these easy-to-operate tricks to solve your shot blasting inefficiency problem.

Trick 1: Optimize Machine Shot Selection and Management for Better Shot Blasting Efficiency

The quality and management of machine shot are key factors affecting shot blasting machine efficiency—many inefficiencies stem from improper machine shot use.

- Select the right machine shot: choose spherical steel shot with uniform particle size (1.0-1.5mm) matching your shot blasting machine model and workpiece requirements. Oversized machine shot increases equipment load and reduces shot blasting speed, while undersized machine shot requires longer processing time to achieve the desired effect.

- Maintain machine shot cleanliness and dryness: damp or contaminated machine shot agglomerates easily, blocking the shot blasting machine’s pipelines and nozzles, leading to frequent downtime for cleaning. Regularly filter machine shot to remove impurities and moisture, and store it in a dry warehouse.

- Recycle and replenish machine shot timely: a shot blasting machine with insufficient machine shot cannot achieve full coverage, requiring repeated shot blasting; recover usable machine shot through the equipment’s recycling system and replenish new shot regularly to maintain the optimal shot amount. Proper machine shot management can improve shot blasting efficiency by 30% and reduce material waste.

Trick 2: Adjust Shot Blasting Machine Parameters to Maximize Operational Efficiency

Incorrect parameter settings are a common cause of low shot blasting machine efficiency—many users keep default parameters unchanged regardless of workpiece type, wasting energy and time.

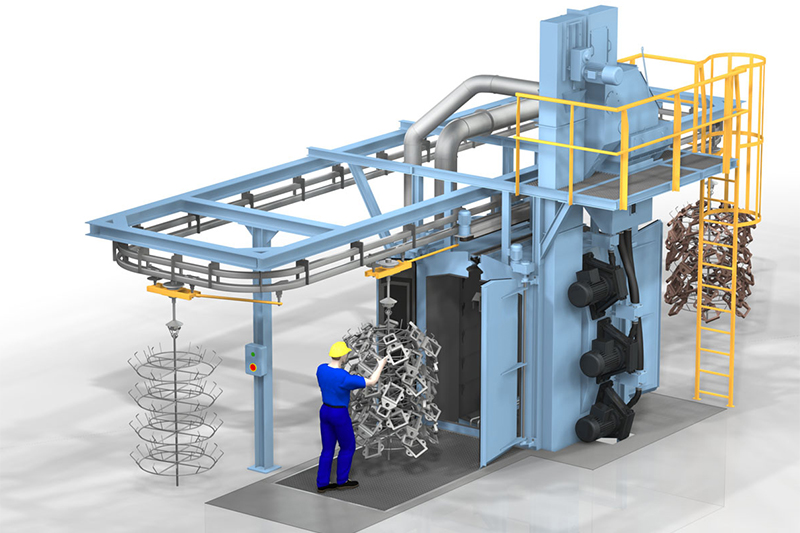

- Adjust the shot blasting intensity and impeller speed: for different workpiece materials and surface requirements, set the appropriate impeller speed (1500-1800rpm) and shot blast pressure (0.6-0.8MPa). For example, thinner workpieces require lower intensity to avoid damage, while thicker workpieces need higher intensity to ensure thorough shot blasting.

- Optimize the nozzle angle and distance: adjust the nozzle to a 45-60° angle relative to the workpiece surface, and keep the distance at 200-300mm—this ensures uniform shot blasting coverage and reduces redundant operations.

- Adjust the feeding speed: match the workpiece feeding speed to the shot blasting machine’s processing capacity; too-fast feeding leads to incomplete shot blasting (requiring rework), while too-slow feeding wastes equipment capacity. Fine-tuning these parameters can significantly improve shot blasting machine efficiency without additional equipment investment.

Trick 3: Conduct Regular Maintenance to Keep the Shot Blasting Machine in Optimal Condition

Neglecting regular maintenance leads to gradual wear of the shot blasting machine’s components, reducing efficiency and increasing fault rates.

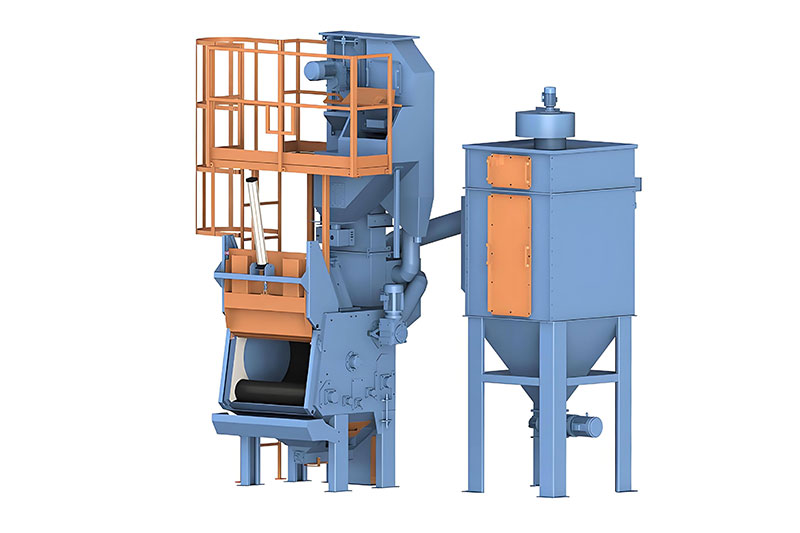

- Inspect and replace worn parts timely: components such as nozzles, impellers, and conveyor belts wear quickly during shot blasting—worn nozzles reduce machine shot output, while worn impellers affect shot acceleration. Check these parts weekly and replace them when wear exceeds 10% to ensure stable performance.

- Clean and lubricate the shot blasting machine regularly: after daily operation, clean the machine’s inner cavity, pipelines, and nozzles to remove residual machine shot and debris; lubricate the impeller bearings, conveyor chains, and other moving parts with anti-wear lubricating oil every 2 weeks to reduce friction and energy consumption.

- Check the electrical and pneumatic systems: loose wires or insufficient air pressure can cause the shot blasting machine to run unstable or shut down unexpectedly. Regularly inspect the power supply, cables, and air compressor to ensure they work normally. Regular maintenance not only improves shot blasting efficiency but also extends the service life of the shot blasting machine.

Conclusion

Optimize machine shot, adjust parameters and maintain regularly to boost efficiency quickly.

For more advice on shot blasting machine optimization,

contact us via email:[email protected]