- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Vacuum Molding (V-process molding)

Vacuum Molding (V-process molding)

- High quality of casting surface.

- Low cost of manufactured castings.

- Excellent dimensional accuracy.

- Environmental friendliness (mold without a binder and under constant vacuum venting of gases).

- Simple maintenance, stability and repeatability of castings quality (no flaws of the green sand).

- The density of castings (another metal structure and unprecedented reduction in gas inclusions)

- Superb mold filling rate.

- No need for taking into consideration the patter draft – less time-consuming and ineffective post-casting machining

- Molding process noise elimination

Product Parameters

Applications

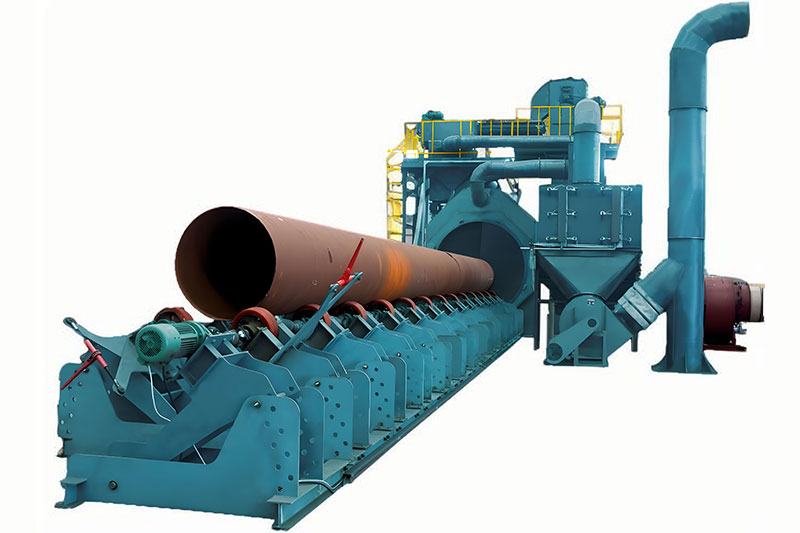

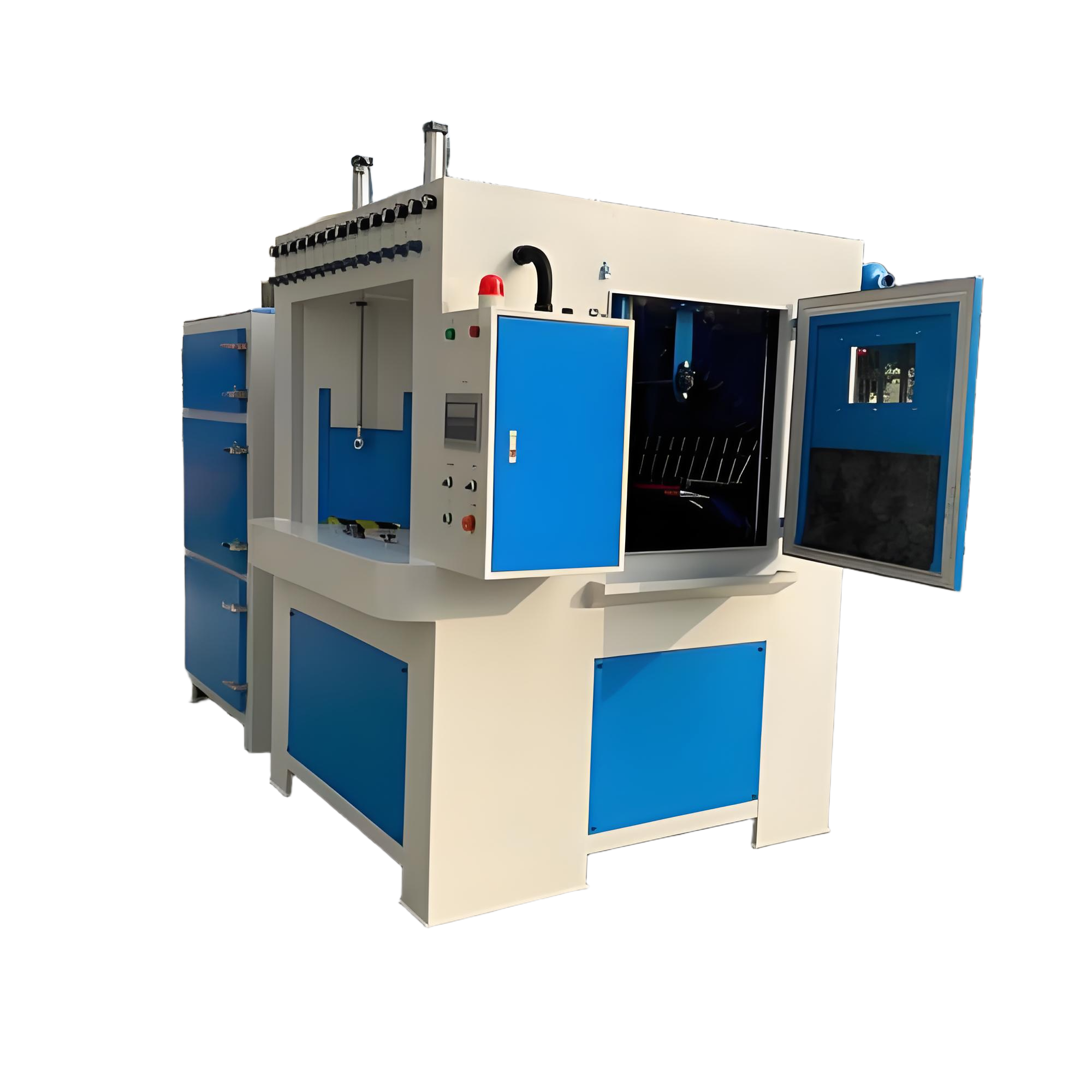

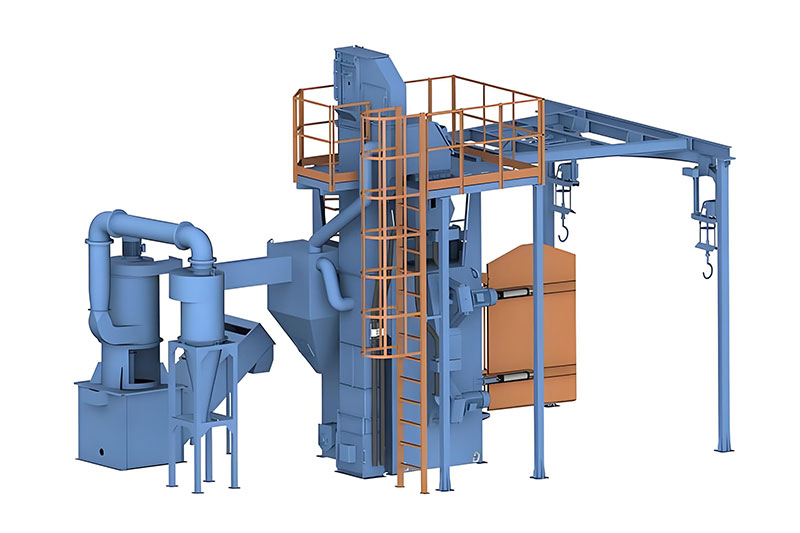

V-Process Casting System is a dry sand cast molding machine that uses no adhesives and is based on pressure generated by a vacuum pump to create vacuum-sealed conditions. It has the advantages of being environmentally friendly, energy efficient and efficient.It is the best choice for rapid prototyping, mainly suitable for the production of cast iron, cast steel, non-ferrous metal castings. So far, V process has been successfully applied in the construction machinery counter weight, petroleum machinery(including crank, reduction case, counterweight), sanitation ware,belt pulley, swing bolster, axle, brake drum, piano plane, manhole cover, high manganese steel lining board.

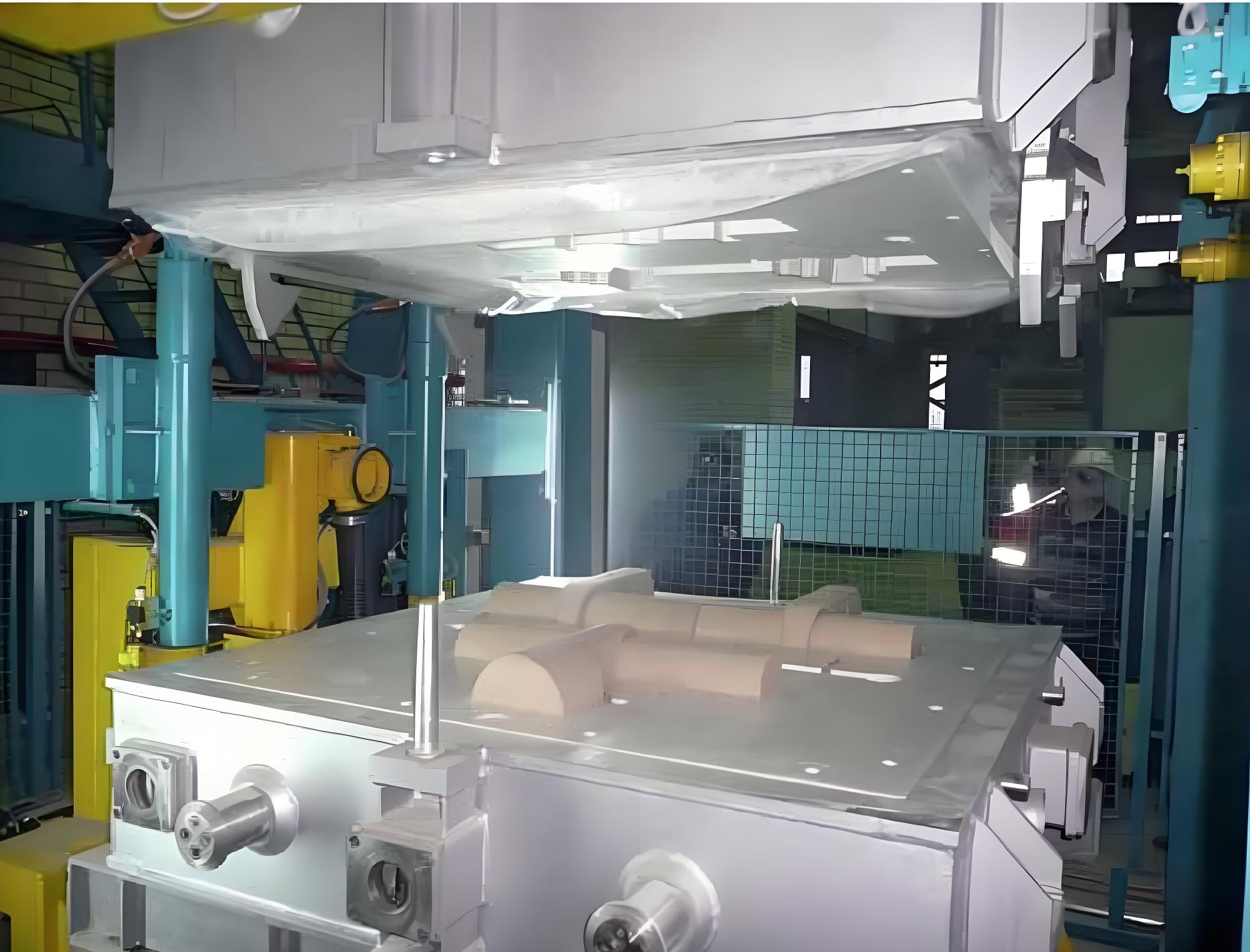

For high-quality castings, the V-Process vacuum molding Machine uses clean, dry binder-free sand between two plastic films to create a dimensionally accurate casting. With this process, there is no need for mullers, mixers, or reclamation and reconditioning equipment.

The V-Process is based on generating a vacuum when a thermo-plastic contour foil is deep drawn over an appropriately prepared pattern, in order to maintain the mold shape in sand without binding material, right through the stages of pouring, cooling and emptying.

Main Benefits

- High quality of casting surface.

- Low cost of manufactured castings.

- Excellent dimensional accuracy.

- Environmental friendliness (mold without a binder and under constant vacuum venting of gases).

- Simple maintenance, stability and repeatability of castings quality (no flaws of the green sand).

- The density of castings (another metal structure and unprecedented reduction in gas inclusions)

- Superb mold filling rate.

- No need for taking into consideration the patter draft – less time-consuming and ineffective post-casting machining

- Molding process noise elimination

Model & Specification

| Internal size of molding box (mm) | Molding efficiency (mold/h) | Annual output | Sand processing capacity(t/h) | Products |

| 2000*1400*320/360mm | 8-10 | 1000 | 5 | Rear axde,brake drum,counter weight |

| 1200*1200*250/300mm 1200*1200*400/450mm 1200*1200*600/600mm | 5-7 | 1000 | 5 | Wear resistant seel castings, steel gratings |

| 1600*1250*500/300mm 2800*2000*350/350mm | 6 | 1000 | 5-10 | Single piece and small batch of castings |

| 1750*1600*650/450mm | 5-10 | 1000 | 5-10 | Gray iron castings, counter weight for forklifts, loaders etc |

| 1000*630*150/150mm 1000*800*150/150mm | 10-15 | 600-1000 | 5 | Stainless steel castings, such as acid resist pump impeller |

| 2000*1600*360/310mm | 10 | 30000 | 35-40 | Rear axde for trucks |

| 3100*1900*450/450mm 3100*1900*350/550mm | 20 | 50000 | 50 | Steel castings for railway parts, bottom bolster, side frame |

Note: Above parameters are just for reference,

We make tailor made and turnkey project for vacuum molding line, you can contact and get the design for your particular needs.

Feature

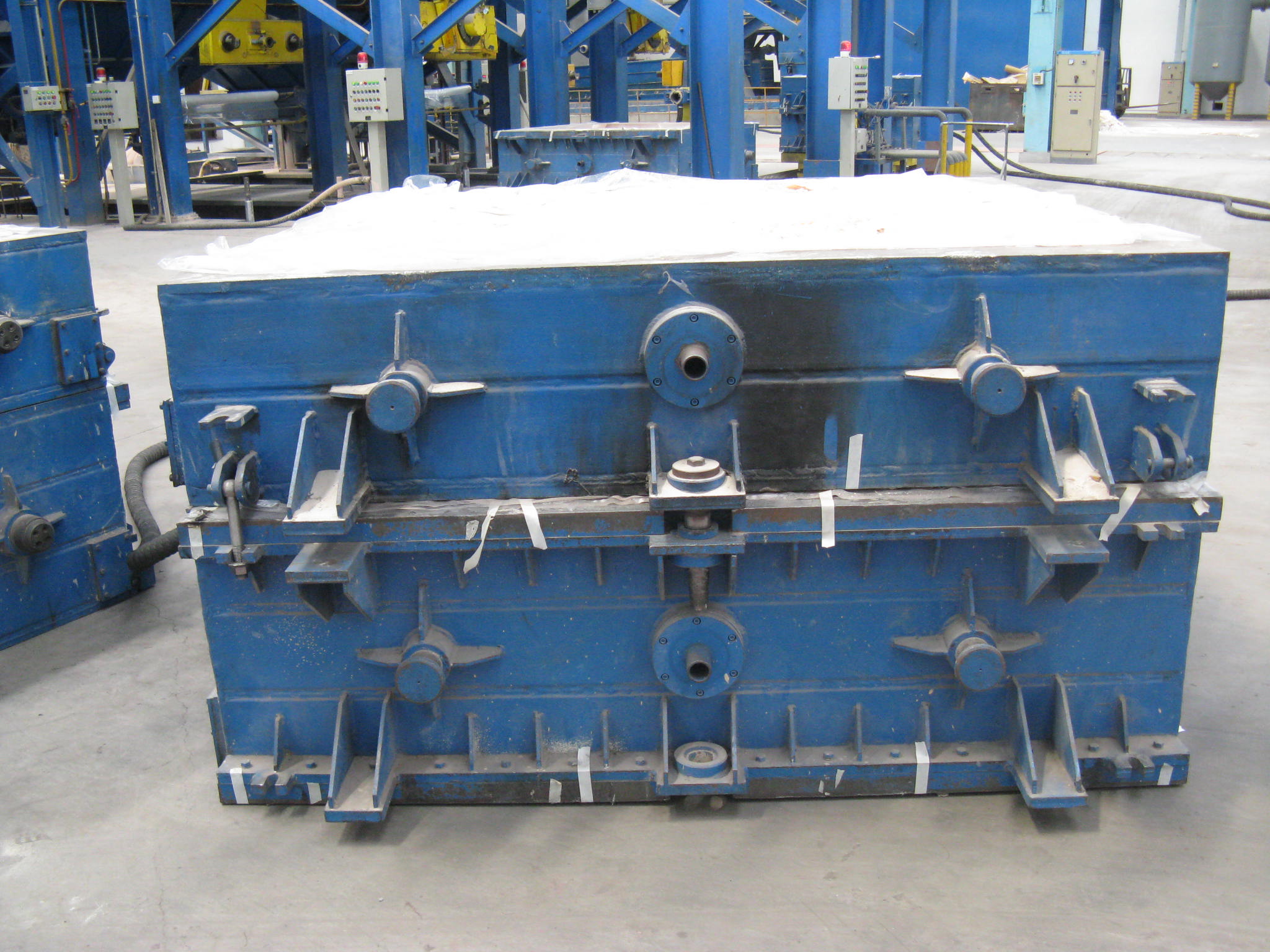

- Due to no high pressure squeezing, Vacuum molding can use wood mould, which is low cost.

- Automatic film cutter

- For better forming, the film need to be heated before cover on the wood mould.

- Due to no high pressure squeezing, Vacuum molding can use wood mould, which is low cost.

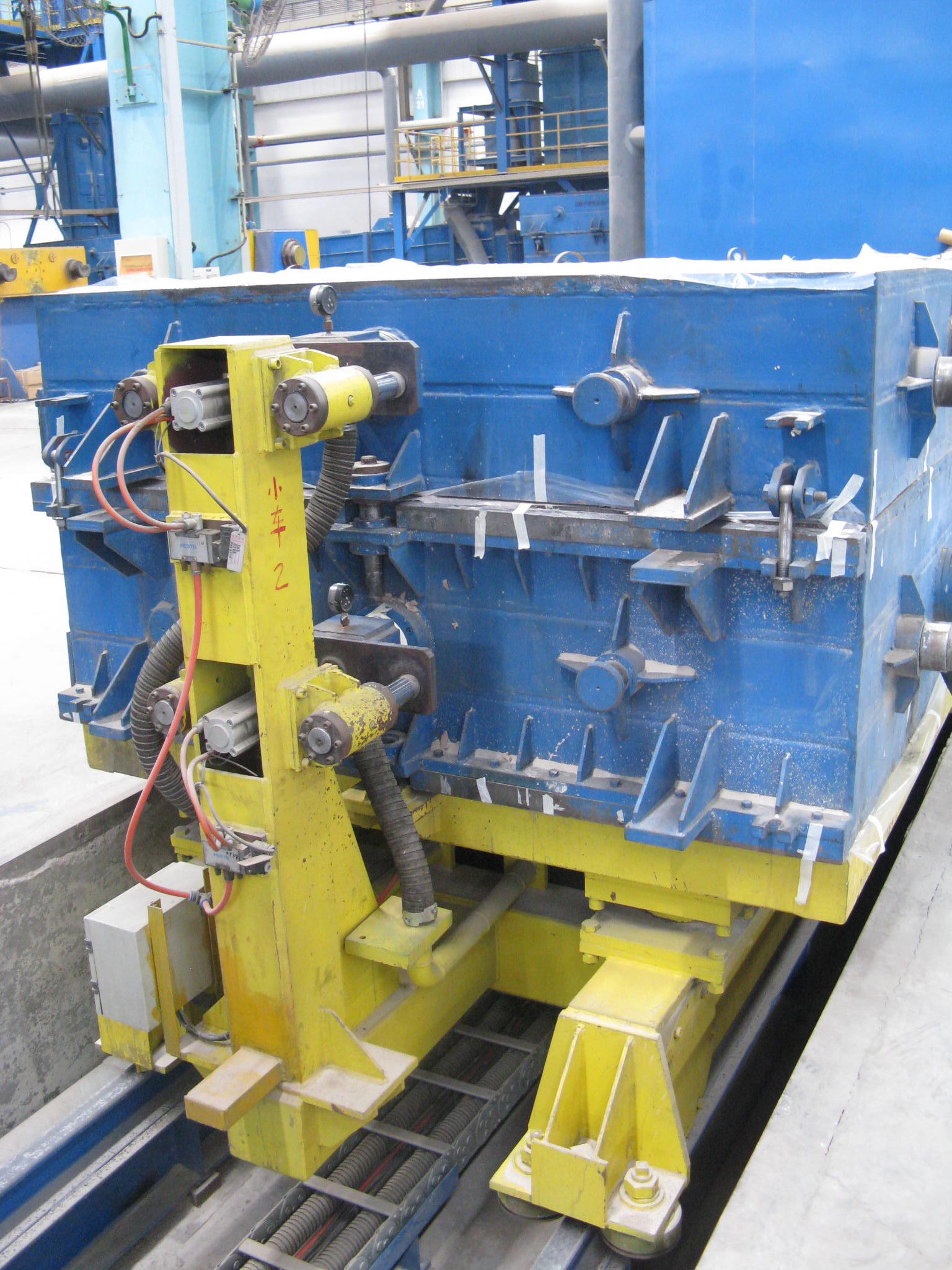

- Carbon steel welded flask with high precision machining

- For high automation, transfer carts are needed