- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

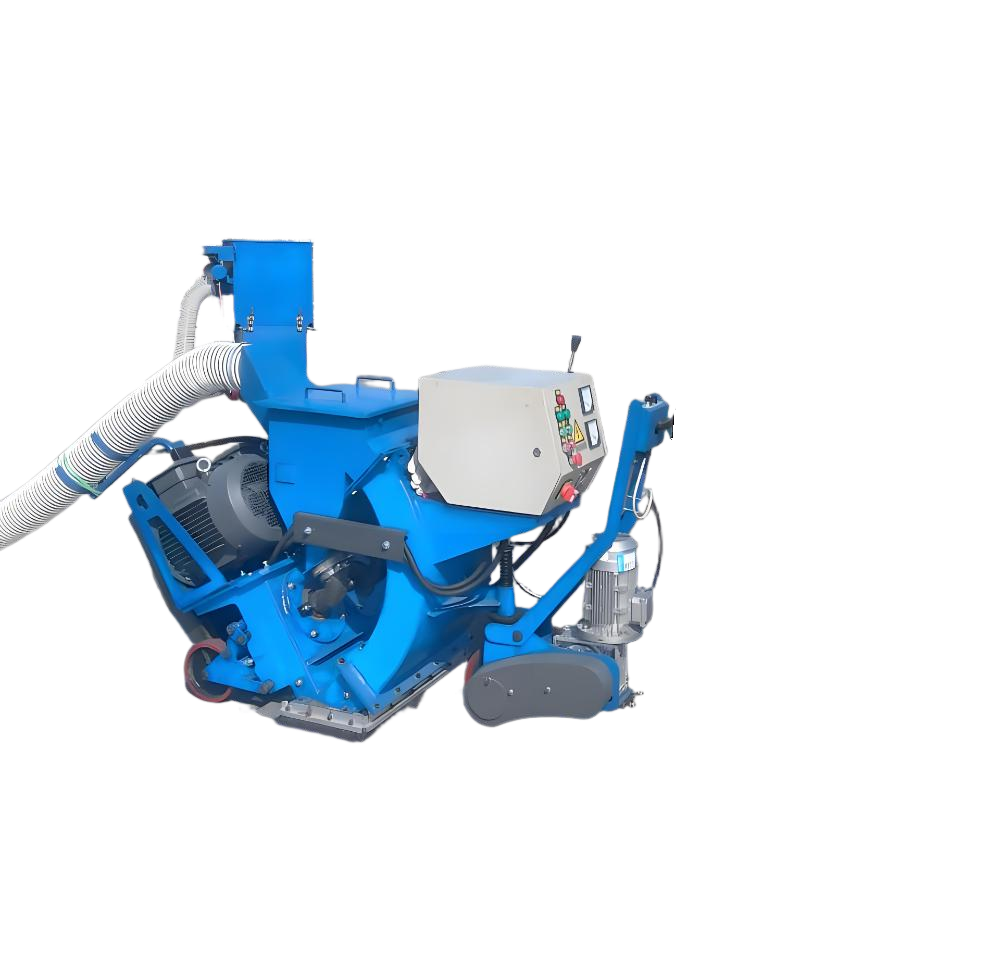

Vacuum blasting machine

Vacuum blasting machine

- 100% dust free operation because of fully automatedblasting & vacuum start/stop sequence

- Clean, abrasive free object surface after blasting;

- Easy disposal of collected dust in plastic bags;

- Unit can be relocated and/or transported easily;

- Wide range of brushes to fit all (flat, cornered,radiused) surfaces;

- Suited for all abrasives, also ‘heavy ones’ like steel shot or chilled iron grit;

Quote Now

Product Parameters

Applications

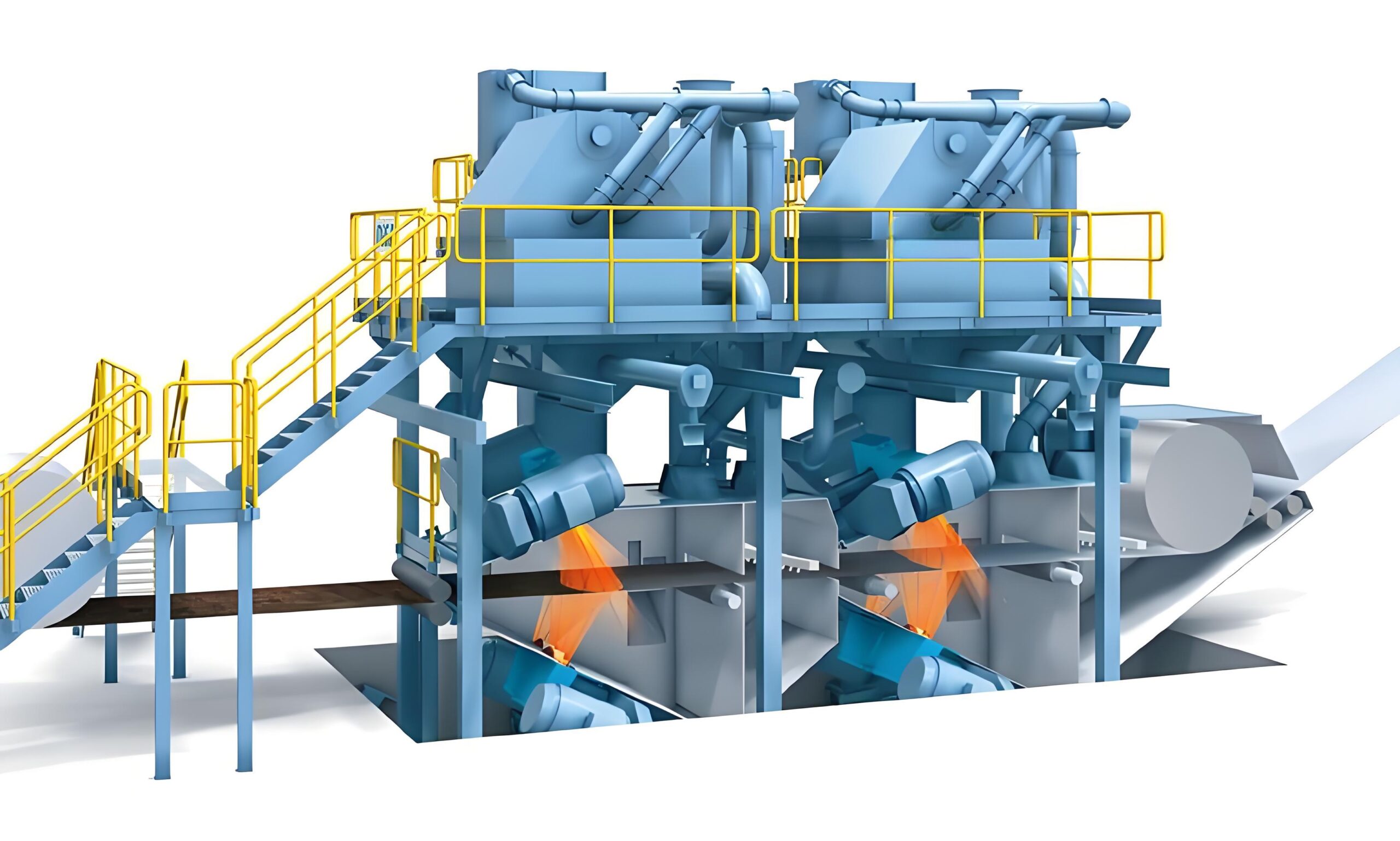

The vacuum blast units combine a blast machine, vacuum pump, and dust collector into a single, compact system, providing a complete dust-free blasting solution.

Vacuum blasting systems shine in scenarios where open-air blasting is restricted due to stricter regulations or where transporting every blast job to a blast chamber isn’t feasible. Here are some ideal situations for using vacuum blasting systems:

- Onsite Blasting with Dust Control: Perfect for jobs that cannot be fully enclosed with a containment system, offering superior dust control.

- Lead-Based Coating Removal: Ideal for removing hazardous coatings, though ensuring HEPA filtration may be necessary.

- Compact Workspaces: Suitable for projects requiring minimal disruption and dust containment in confined or regulated environments.

- High-Precision Jobs: When the surface requires precise blasting with minimal abrasive loss and reduced cleanup times.

Main Benefits

- 100% dust free operation because of fully automatedblasting & vacuum start/stop sequence

- Clean, abrasive free object surface after blasting;

- Easy disposal of collected dust in plastic bags;

- Unit can be relocated and/or transported easily;

- Wide range of brushes to fit all (flat, cornered,radiused) surfaces;

- Suited for all abrasives, also ‘heavy ones’ like steel shot or chilled iron grit;

Model & Specification

| No. | Iteam | VB20 | VB30 |

| 1. | Motor Power | 7.5Kw | 11Kw |

| 2. | Air volume | 600m3/h | 600m3/h |

| 3. | Volume | 200L | 300L |

| 4. | Air pressure | 0.4-0.6 MPa | 0.4-0.7MPa |

| 5. | Consumption Volume | 6.1m3/min | 6.1m3/min |

| 6. | Suction hose | 15m | 50m |

| 7. | Clean speed | 6-15m2/h | 6-15m2/h |

| 8. | Steel shot (DIA) | 0.8-1.0mm | 0.8-1.0mm |

| 9. | Cleaning efficiency | 6-15m2/h | 6-15m2/h |

| 10. | Nozzle size | 6-7.9mm | 6-7.9mm |

| 11. | Equipment Dimension | 1800L*800W*1700H | 1800*1900*2500mm |

| 12. | Equipement Weight | 500 Kg | 1000Kg |

| 13. | Package dimensions | 1900*920*2000 mm | 2000*2000*2300mm |

| 14. | Packed weight | 650 Kg | 1200Kg |

We have more vacuum blasting machine models up to 110kw, contact us for more detail.