- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

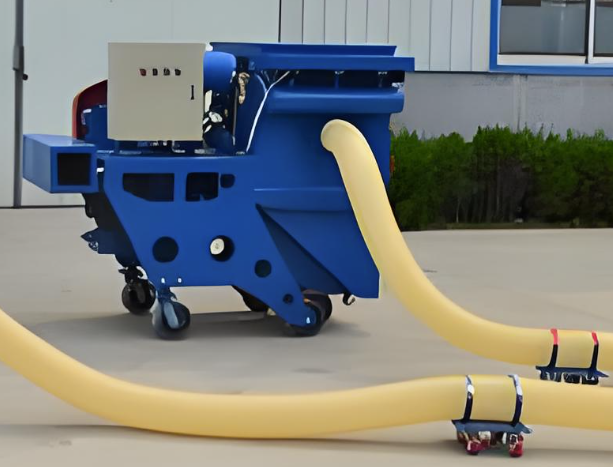

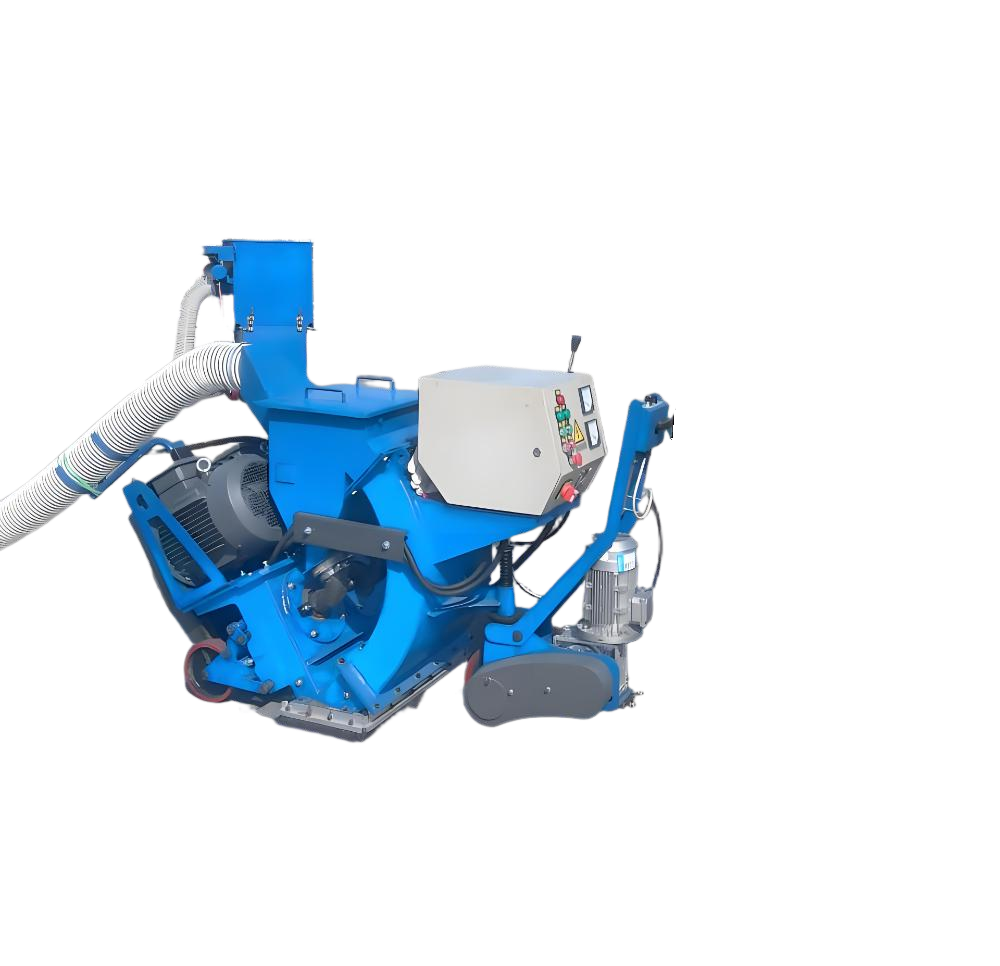

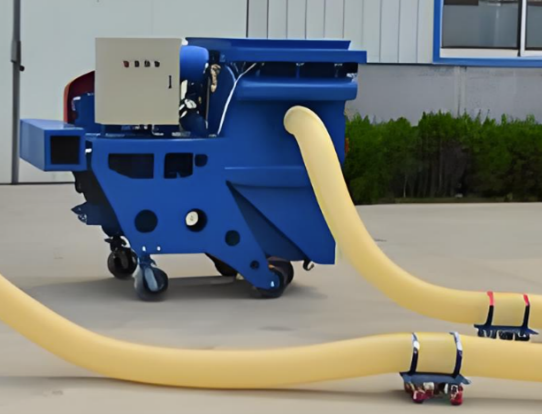

Floor blast machine

Floor blast machine

- High impact, producing exceptional working results

- Simple operation, one person can operate the machine

- The dust collector is connected with chamber by hose to realize dust-free operation

- Long-life filter system

Product Parameters

Applications

The floor shot blasting machine has an AC inverted drive-motor with integrated brake. This improved feature maintain speed on

ramps and inclines, making it the ideal choice for restoring skid resistance and traction in parking garages or on warehouses floors.

This also improves your productivity as it generates a more even and consistent blast pattern and surface profile when preparing for coatings and overlays or when removing line strippings and markings.

The machine transports easily and has highly visible and manageable controls. All electrical components and panels are UL certified as part of our commitment to sound safety practices.

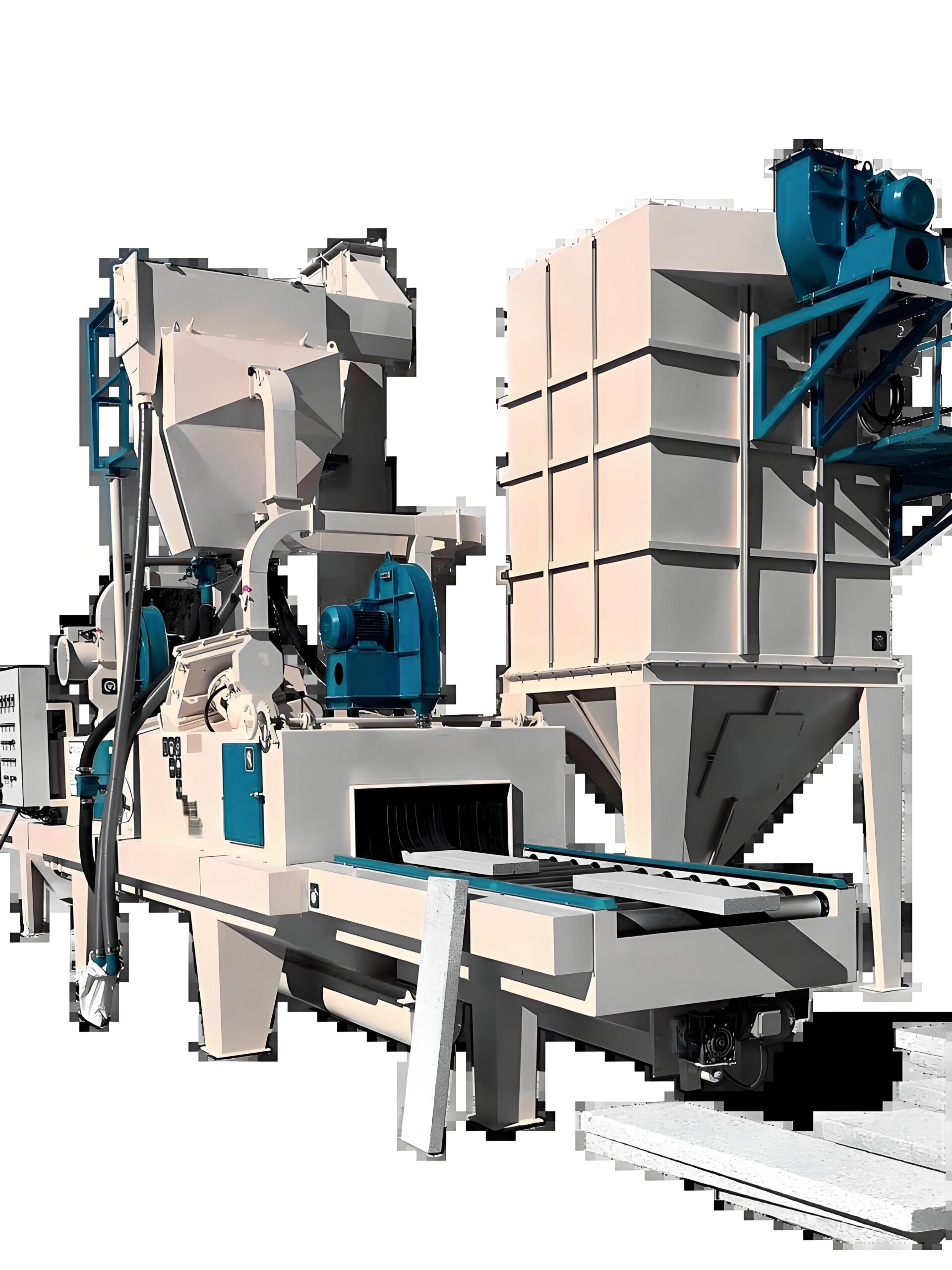

Perfect for industrial floors, warehouses, factory roads and bridges, and supermarkets. It is an environmentally sound choice for any surface preparation contractor. It is also widely used for blast the ship deck and hull in ship building industry. Flat steel sheet can also be blasted on the floor when it moves pass through it.

Main Benefits

- High impact, producing exceptional working results

- Simple operation, one person can operate the machine

- The dust collector is connected with chamber by hose to realize dust-free operation

- Long-life filter system

Model & Specification

| Type | PW-270 | PW-420 | PW-550 | PW-850 |

| Shot blast cleaning range(mm) | 270 | 420 | 550 | 850 |

| Cleaning efficiency(m²/h) | >180 | >200 | >400 | >600 |

| Blast motor power(kw) | 11 | 2*7.5 | 2*11 | 2*15 |

| Machine weight(kg) | 325 | 350 | 560 | 780

|

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

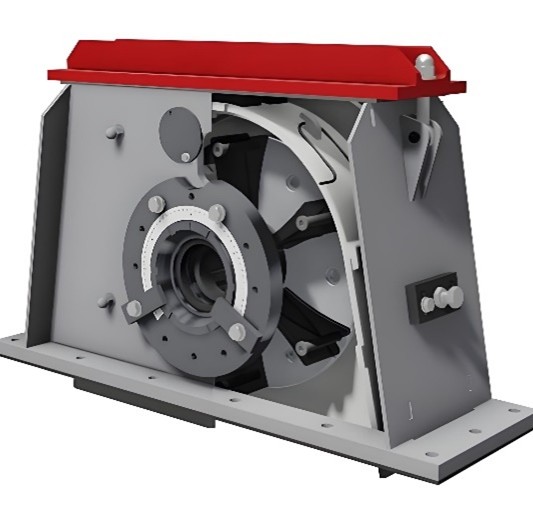

- One or two blast turbine for different blasting width

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

- Vacuum sucking makes the blasting process no dust emission

- Sucking ducting from 10m to 80m