Traditional shot blasting causes high pollution and energy waste; green shot blasting machines solve these issues to meet strict environmental standards.

This article explores key development trends (policy-driven, energy-saving, intelligent) and core technological breakthroughs of green shot blasting machines, guiding industry transformation.

Dive into the following sections to grasp the future of shot blasting and green equipment innovation.

What Are the Core Development Trends of Green Shot Blasting Machines?

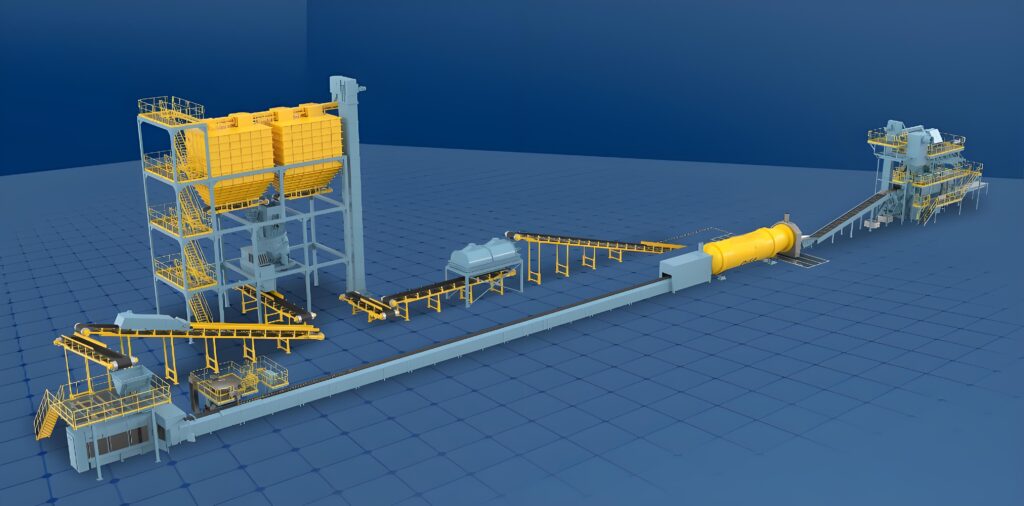

Green shot blasting machines are evolving around three core trends driven by policy, market demand and technological progress. First, policy-mandated environmental compliance: global standards like China’s GB 30254-2026 now require particulate emissions ≤10 mg/m³, steel shot recovery ≥98% and noise ≤75 dB(A), forcing the phase-out of high-pollution models. Regions like the Beijing-Tianjin-Hebei region have even stricter local limits, accelerating the upgrade of existing shot blasting equipment. Second, energy-saving and resource-circulating design: the industry is shifting from high-energy consumption to low-power operation, with first-class energy efficiency motors reducing power consumption by 10-15% compared to traditional models. Resource recycling has become a priority, with closed-loop abrasive recovery systems minimizing waste and cutting material costs by 20% annually. Third, integration of intelligence and environmental protection: modern shot blasting machines adopt PLC control systems and real-time monitoring platforms to optimize energy use and emissions. The market for such green equipment is booming, with an expected annual growth rate of 12.3% from 2026 to 2030, reaching a market size of 8.64 billion yuan by 2030. These trends reflect the industry’s shift toward sustainable development, making green shot blasting machines the mainstream choice for manufacturing.

What Technological Breakthroughs Have Been Achieved in Pollution Control for Shot Blasting?

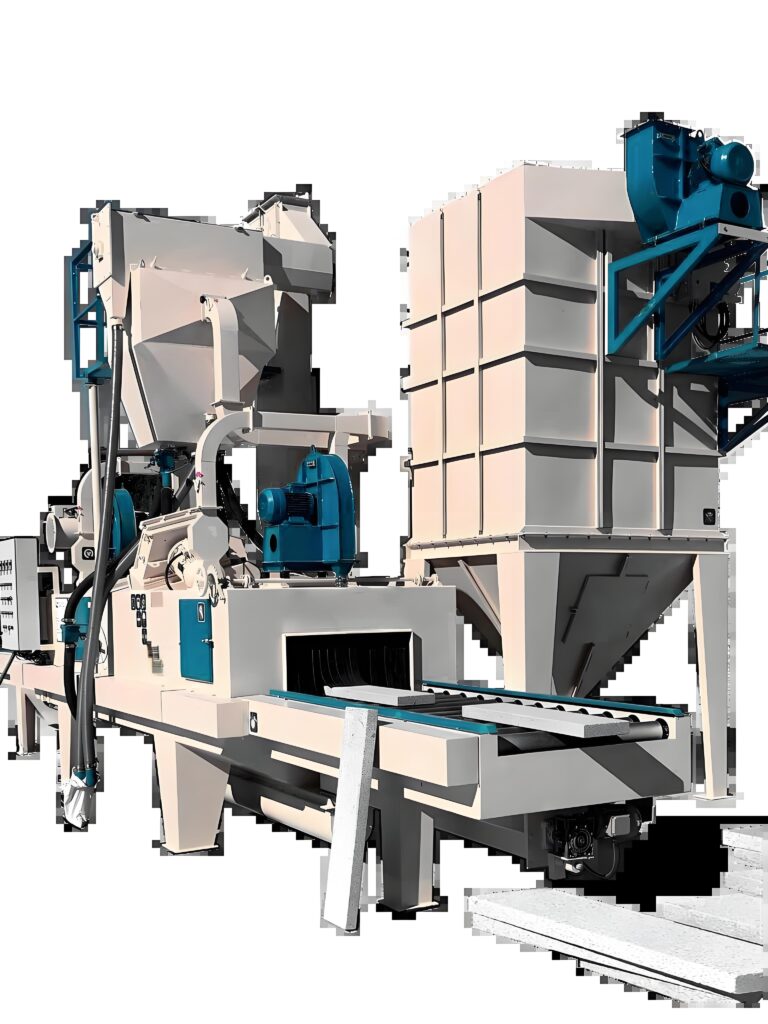

Pollution control is a key technological breakthrough area for green shot blasting machines, with innovations focusing on dust, noise and waste reduction. For dust treatment, advanced combined systems like “cyclone + bag filtration + cartridge dust removal” have raised dust collection efficiency to over 99.9%, as seen in Chongqing Iron and Steel’s upgraded shot blasting machine which reduced on-site dust concentration to below 10 mg/m³. Some enterprises have further adopted “secondary spray + filter cartridge purification” technology to capture fine dust escaping primary filtration. Noise reduction technologies include enclosed sound insulation structures, damping materials and low-noise motors, lowering operating noise to ≤65 dB(A) for sensitive applications. Waste reduction is achieved through high-precision abrasive sorting systems that separate worn and usable steel shot, boosting recovery rates to 98% or higher. Additionally, non-toxic, inert abrasives like recycled glass grit are replacing traditional materials, eliminating heavy metal contamination and enabling safe use in environmentally sensitive areas. These breakthroughs have transformed shot blasting from a high-pollution process to an eco-friendly one, meeting both regulatory requirements and corporate sustainability goals.

How Have Energy-Saving and Intelligent Technologies Advanced Green Shot Blasting Machines?

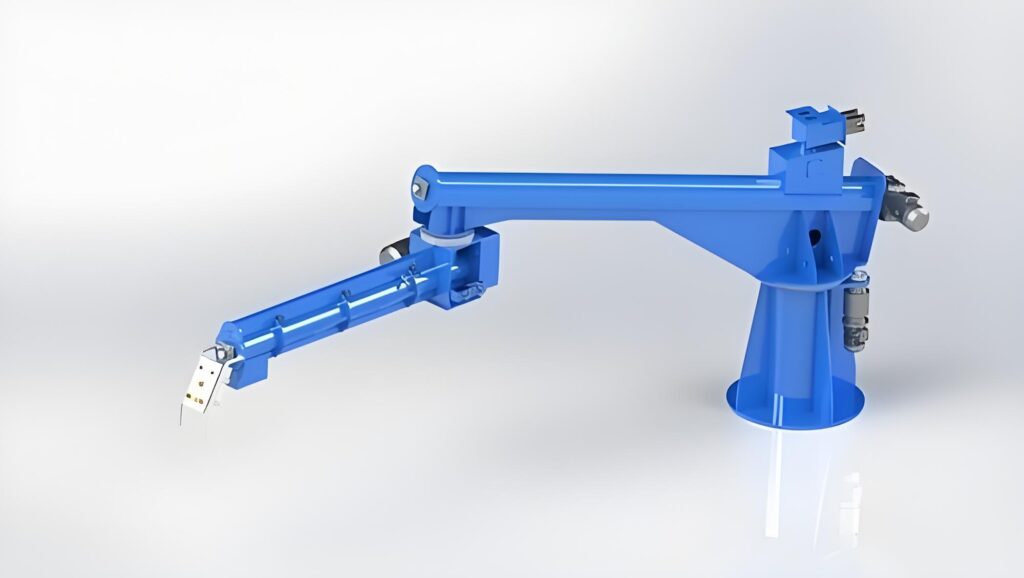

Energy-saving and intelligent technologies are revolutionizing the performance of green shot blasting machines. Energy-saving innovations start with component optimization: lightweight wear-resistant parts reduce equipment load, while variable frequency drives adjust operation speed based on workpiece requirements, avoiding “high-power low-efficiency” waste. Heat recovery systems capture waste heat from operation to meet 20-30% of workshop heating needs, further cutting energy consumption. On the intelligent front, modern shot blasting machines integrate laser thickness sensors and AI visual inspection to achieve adaptive shot blasting. For example, Honglin Intelligent’s smart frequency conversion technology automatically adjusts shot intensity and angle based on workpiece surface conditions, improving efficiency by 40% while preventing over-processing. Remote monitoring and predictive maintenance platforms enable real-time tracking of energy use, emissions and equipment status, reducing downtime by 15-20%. These technologies not only lower energy consumption by 15-25% but also enhance processing precision and stability. The integration of energy-saving and intelligent features has become a key competitive advantage, driving the widespread adoption of green shot blasting machines in automotive, wind power and construction machinery industries.

What Is the Application Prospect of Green Shot Blasting Machines in Key Industries?

Green shot blasting machines have broad application prospects across key industries, supported by stricter environmental requirements and industrial upgrading. In the steel and construction sectors, large-scale projects like bridge and ship manufacturing now mandate low-emission shot blasting equipment for surface treatment, with single project purchases reaching hundreds of millions of yuan. The automotive industry, especially new energy vehicle manufacturing, relies on green shot blasting for precision cleaning of engine components and body structures, requiring both environmental friendliness and high surface finish. Infrastructure projects such as urban renewal and high-speed rail construction favor closed-type low-noise models, with their market share in municipal applications rising to 58.3%. Export potential is also growing, as international green trade standards like EU EPD and ISO 14044 recognize high-performance green shot blasting machines, enabling export premiums of up to 8.5%. Small and medium-sized enterprises are adopting these machines through innovative business models like leasing, further expanding market penetration. As industries prioritize sustainability, the demand for green shot blasting will continue to surge, making it an indispensable part of modern manufacturing’s green transformation.

Conclusion

Green shot blasting machines lead the industry with environmental, energy-saving and intelligent advancements.