- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Shell mold casting (shell molding)

Shell mold casting (shell molding)

Superior Surface Finish: The use of fine silica sand and a resin binder creates a much smoother mold cavity compared to coarser traditional sand molds.

High Dimensional Accuracy: The rigidity and stability of the cured resin-sand shell contribute to exceptional dimensional accuracy and consistency from one part to another.

Ability to Cast Complex Geometries: The excellent flowability of the sand-resin mixture allows it to capture intricate details and thin sections of the pattern.

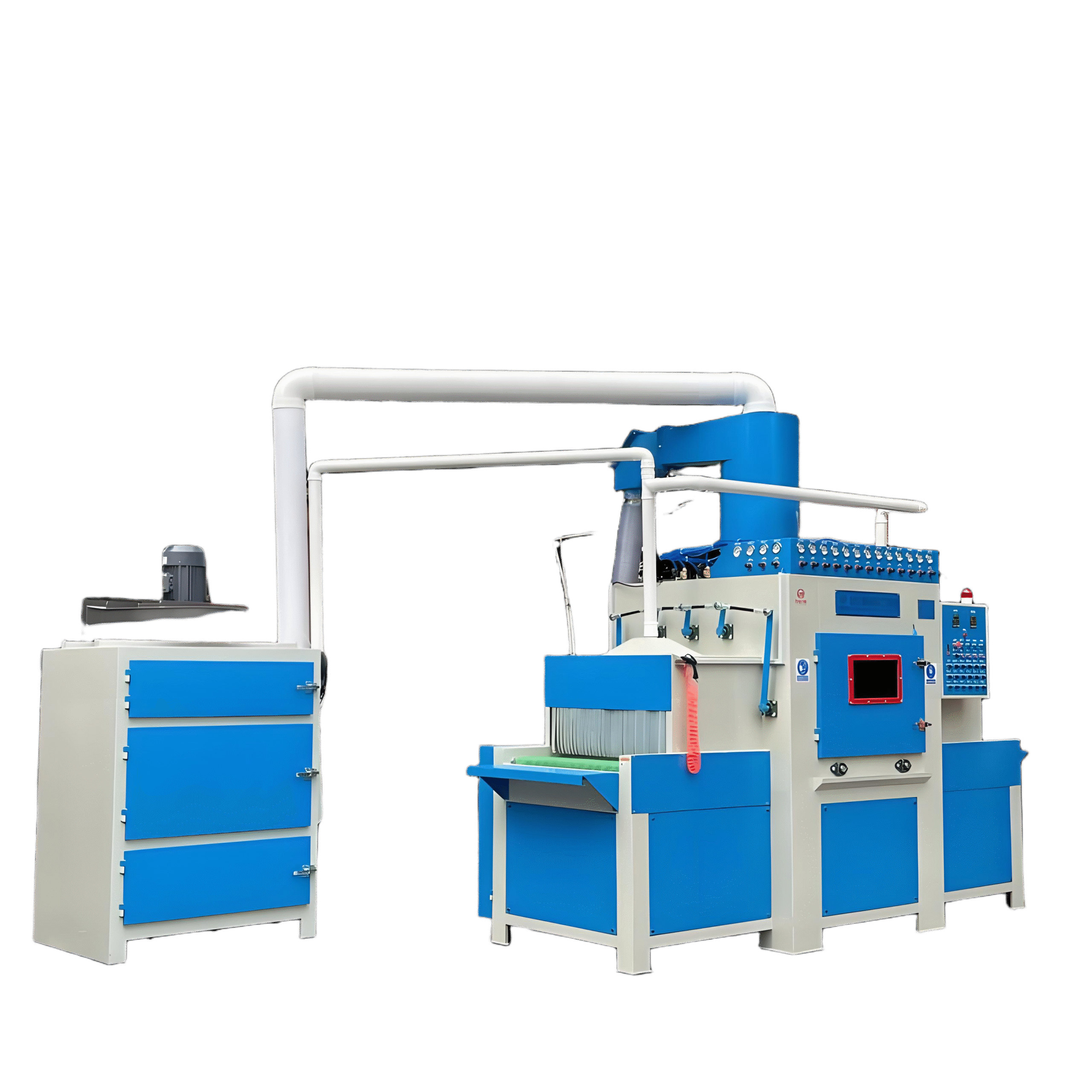

Product Parameters

Applications

Shell molding is also known Croning process. Shell mold casting or shell molding is a metal casting process in manufacturing industry in which the mold is a thin hardened shell of sand and thermosetting resin binder, backed up by some other material.

Typical parts manufactured in industry using the shell mold casting process include cylinder heads, gears, bushings, connecting rods, camshafts and valve bodies.

Main Benefits

Superior Surface Finish: The use of fine silica sand and a resin binder creates a much smoother mold cavity compared to coarser traditional sand molds.

High Dimensional Accuracy: The rigidity and stability of the cured resin-sand shell contribute to exceptional dimensional accuracy and consistency from one part to another.

Ability to Cast Complex Geometries: The excellent flowability of the sand-resin mixture allows it to capture intricate details and thin sections of the pattern.

Material Versatility: Shell molding is highly versatile and can be used with a wide range of ferrous and non-ferrous metals.

Cost-Effectiveness for Mid-to-High Volumes: While the resin-sand mixture is more expensive than conventional molding sand, the reduced need for extensive post-casting machining and the ability to automate the process contribute to overall cost-effectiveness for medium to high production volumes.

Reduced Machining Requirements: The inherent precision and smooth surface of shell-molded parts directly translate to lower machining costs and lead times, as less material needs to be removed.

We make tailor made and turnkey project for shell molding line, you can contact and get the design for your particular needs.

Feature

- Assemble the shell before put into flask.

- Fill the flask with steel ball after shell put into flask.

- Multi pouring station with dust sucking hood

- After shakeout, steel ball is separated from casting, and need cooling properly.