- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

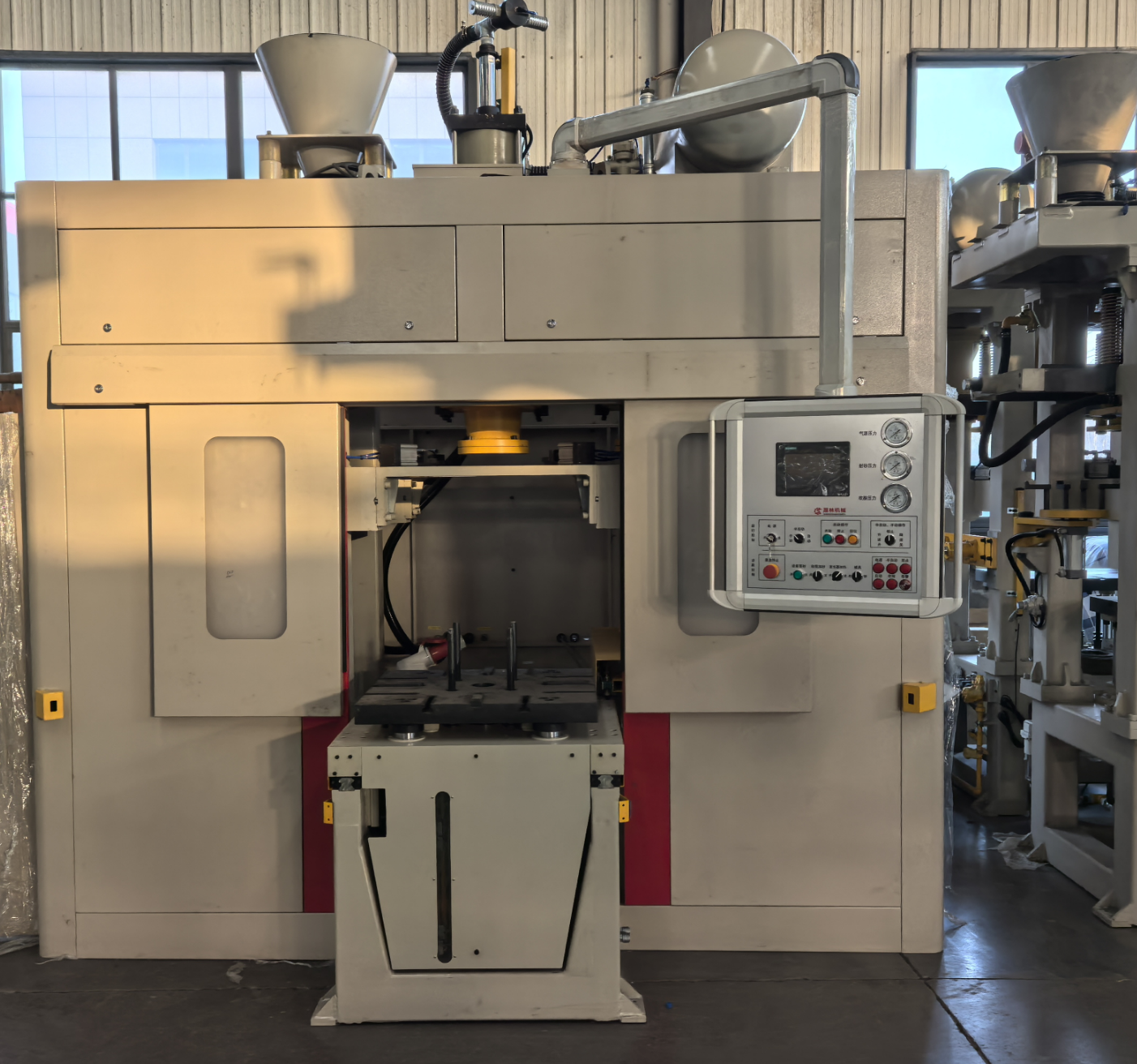

Pass through automatic sand blasting machine

Pass through automatic sand blasting machine

- Higher Efficiency

- Precise Results

- Safer Working Conditions

- Lower Costs in the Long Run

- Broad Range of Uses

Quote Now

Product Parameters

Applications

Automatic sand blasting machine is advanced systems designed to clean, smooth, or texture surfaces using high-pressure streams of abrasive materials. These machines are programmed to handle repetitive tasks with precision, minimizing human intervention.

Automatic sand blasting machines can finish rough surfaces, descaling, and remove remaining salt, and burrs from forging and casting components, welded parts, heat-treated parts, stamping parts, and machining parts.

Automatic sand blasting allows a batch of workparts pass thru the working chamber for process, which realizes a required big output with uniform quality.

Main Benefits

- Higher Efficiency

- Precise Results

- Safer Working Conditions

- Lower Costs in the Long Run

- Broad Range of Uses

The automatic blasting machine is configured with a high efficiency cartridge type dust collector.

Feature

Adjustable blast guns

- Each blast gun is individually controlled for working or not, as well as allowed to adjust oscillating speed and angle.

- The blast gun group can be set for fixing blasting or oscillating blasting, which depends on the shaped of the being finished objects.

Continuous conveyor

- Pass through type sand blasting machine has several conveyor options:

- Roller conveyor;

- Mesh belt conveyor;

- Rubber belt conveyor;

High efficiency dust collector

- The automatic blasting machine is configured with a high efficiency cartridge type dust collector.