- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Lost Foam Molding

Lost Foam Molding

- The process requires no additives or binders, simplifying production and reducing chemical usage.

- LFC provides exceptional design flexibility, allowing for the creation of complex shapes that would be difficult to achieve with conventional casting methods.

- Traditional cores are not required, further streamlining the manufacturing process.

Product Parameters

Applications

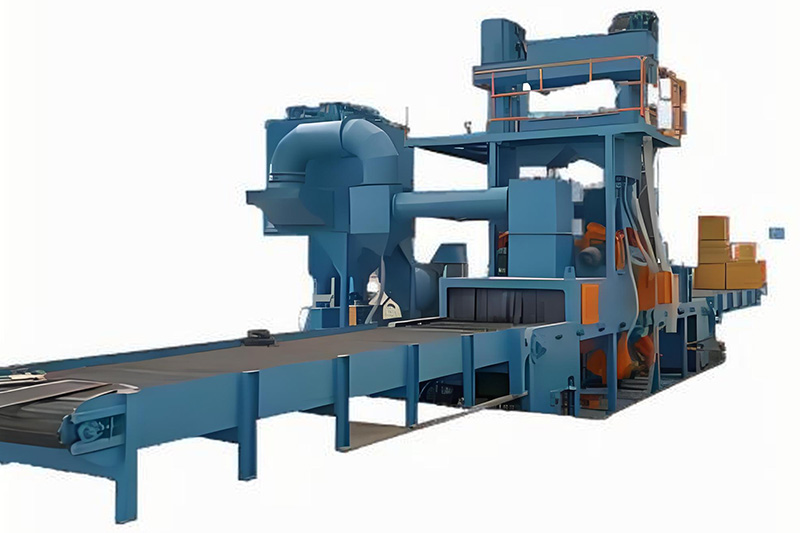

Lost Foam Casting (LFC), also known as Evaporative Pattern Casting, represents a significant advancement in metal manufacturing technology, particularly in the automotive industry. This process uses polystyrene foam patterns that evaporate when molten metal is introduced, creating precise, solid metal components with reduced production costs compared to conventional casting methods. LFC has gained prominence in automotive manufacturing due to its ability to produce lightweight aluminum engine components, contributing to improved fuel efficiency and reduced vehicle weight.

It does not need to close the box to take the mould and uses binder-free dry sand to reduce pollution. The application range includes the Automotive industry, Construction Machinery, Machine tool industry, Mining machinery, cement machinery, Petroleum Machinery, Sanitary ware, etc.

Main Benefits

The LFC process offers numerous advantages that make it increasingly attractive for modern manufacturing:

- The process requires no additives or binders, simplifying production and reducing chemical usage.

- LFC provides exceptional design flexibility, allowing for the creation of complex shapes that would be difficult to achieve with conventional casting methods.

- Traditional cores are not required, further streamlining the manufacturing process.

Model & Specification

| Internal size of moulding box (mm) | Moulding efficiency (mold/h) | Annual output | Sand processing capacity (t/h) | Products |

| 2000×1400×320/360mm | 8~10 | 10,000 | 5 | rear axle, brake drum, counterweight |

| 1200×1200×250/300mm 1200×1200×400/450mm 1200×1200×600/600mm | 5~7 | 10,000 | 5 | wear-resistant steel castings, steel gratings |

| 1600×1250×500/300mm 2800×2000×350/350mm | 6 | 10,000 | 5~10 | single piece and a small batch of castings |

| 1750×1600×650/450mm | 5~10 | 10,000 | 5~10 | grey iron castings, counterweight for forklifts, loaders |

| 1000×630×150/150mm 1000×800×150/150mm | 10~15 | 600~1,000 | 5 | stainless steel castings, such as acid-resistant pump impeller |

| 2000×1600×360/310mm | 10 | 30,000 | 35~40 | rear axle for trucks |

| 3100×1900×450/450mm 3100×1900×350/550mm | 20 | 50,000 | 50 | steel castings for railway parts, bottom bolster, side frame |

We make tailor made and turnkey project for lost foam casting, you can contact and get the design for your particular needs.

Feature

- High quality carbon steel welded flask

- Pouring platform easy pass to each flask

- Dust sucking hood to reduce heavy smoke in workshop

- Automatic transfer cart to improve the flow process

- Vacuum system makes the sand mould easy to form.