- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Green Sand Preparation Line

Green Sand Preparation Line

- Consistent Mixing: Blends sand (silica, olivine, chromite), clay (bentonite), water, and additives (coal dust, cereals) to ensure uniform strength, permeability, and moisture.

- Sand Reclamation: Recycles used sand by removing binders/debris, reducing waste and material costs.

- Conditioning: Adjusts properties like compactability and flowability for optimal mold formation.

- Automation and Scalability: Handles high-volume production in large foundries or smaller batches for specialized shops.

Quote Now

Product Parameters

Applications

Industries Served:

- Automotive: Engine blocks, cylinder heads, brake components.

- Heavy Machinery: Construction equipment, agricultural machinery parts.

- Pipe and Valve Manufacturing: Fittings, pumps, valves.

- Art and Sculpture: Custom metal artworks.

- Process Support: Creates molds for ferrous (iron, steel) and non-ferrous (aluminum, brass) alloys, adjusting sand properties for different metals.

Key Function of the preparation line

- Consistent Mixing: Blends sand (silica, olivine, chromite), clay (bentonite), water, and additives (coal dust, cereals) to ensure uniform strength, permeability, and moisture.

- Sand Reclamation: Recycles used sand by removing binders/debris, reducing waste and material costs.

- Conditioning: Adjusts properties like compactability and flowability for optimal mold formation.

- Automation and Scalability: Handles high-volume production in large foundries or smaller batches for specialized shops.

Main Benefits

- Higher Efficiency

- Precise Results

- Safer Working Conditions

- Lower Costs in the Long Run

- Broad Range of Uses

Model & Specification

- Defect Prevention: Maintains precise moisture/clay ratios to minimize casting defects (e.g., sand inclusion, porosity).

- Continuous Monitoring: Sensors track moisture, temperature, and strength, enabling real-time adjustments.

- Energy Efficiency: Modern lines optimize power usage during mixing and transportation.

- Waste Reduction: Sand reclamation systems lower disposal needs and raw material costs.

- Dust Control: Integrated filters and containment systems meet regulatory standards for air quality.

The green sand preparation line processing ability from 10T/hr to 200 T/hr, contact our engineer for proposal and design.

Feature

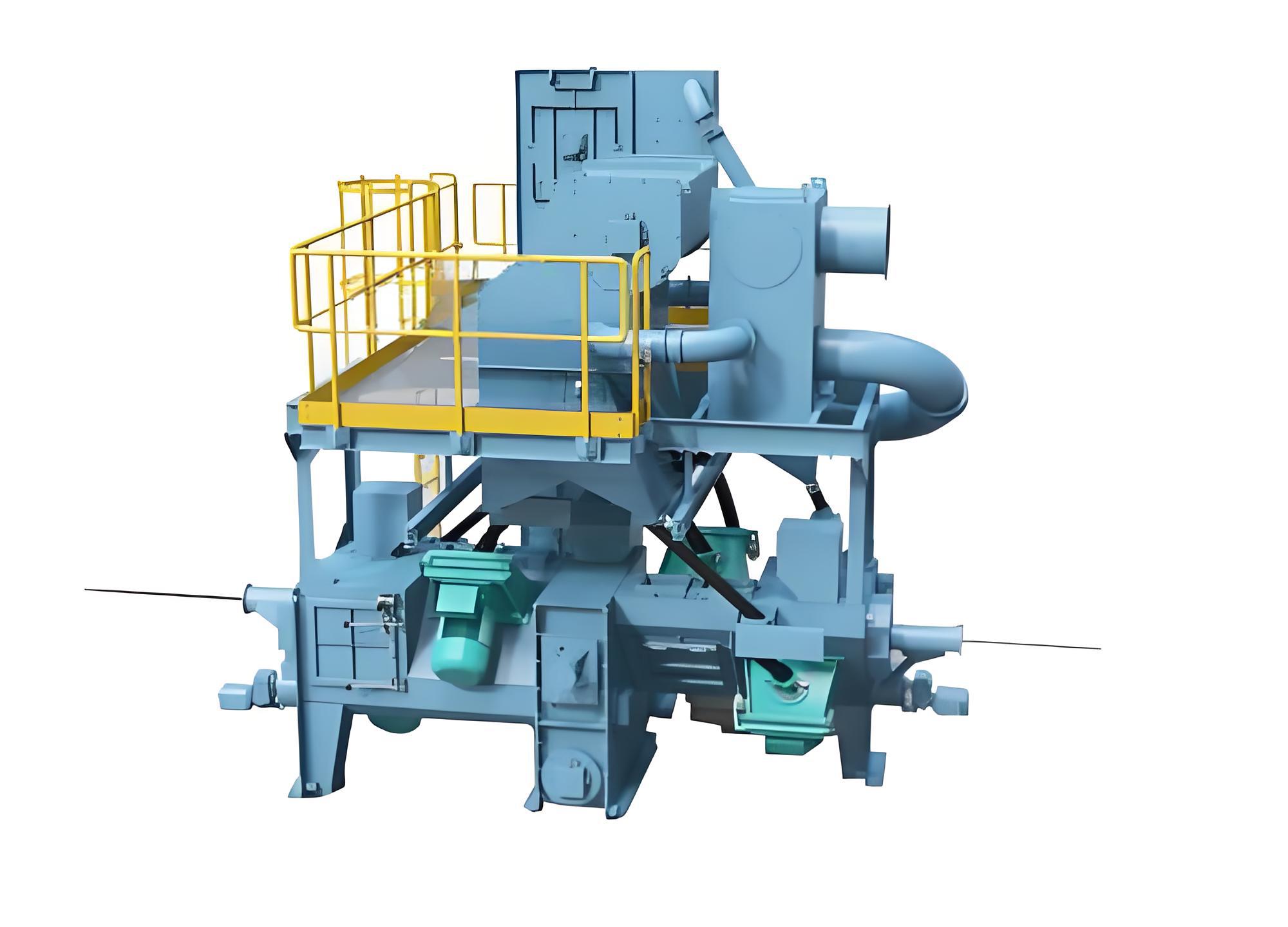

Intensive sand mixer

- two high speed rotator

- bottom lined with durable ceramic

- 10 to 160 ton/h capacity available

On-line automatic sand quality checking system

- Automatic sample sand drawing from sand mixer

- Automatic humidity and tightness testing

- Automatic recording

- Automatic feedback to PLC control

- Automatic control water and sand adding

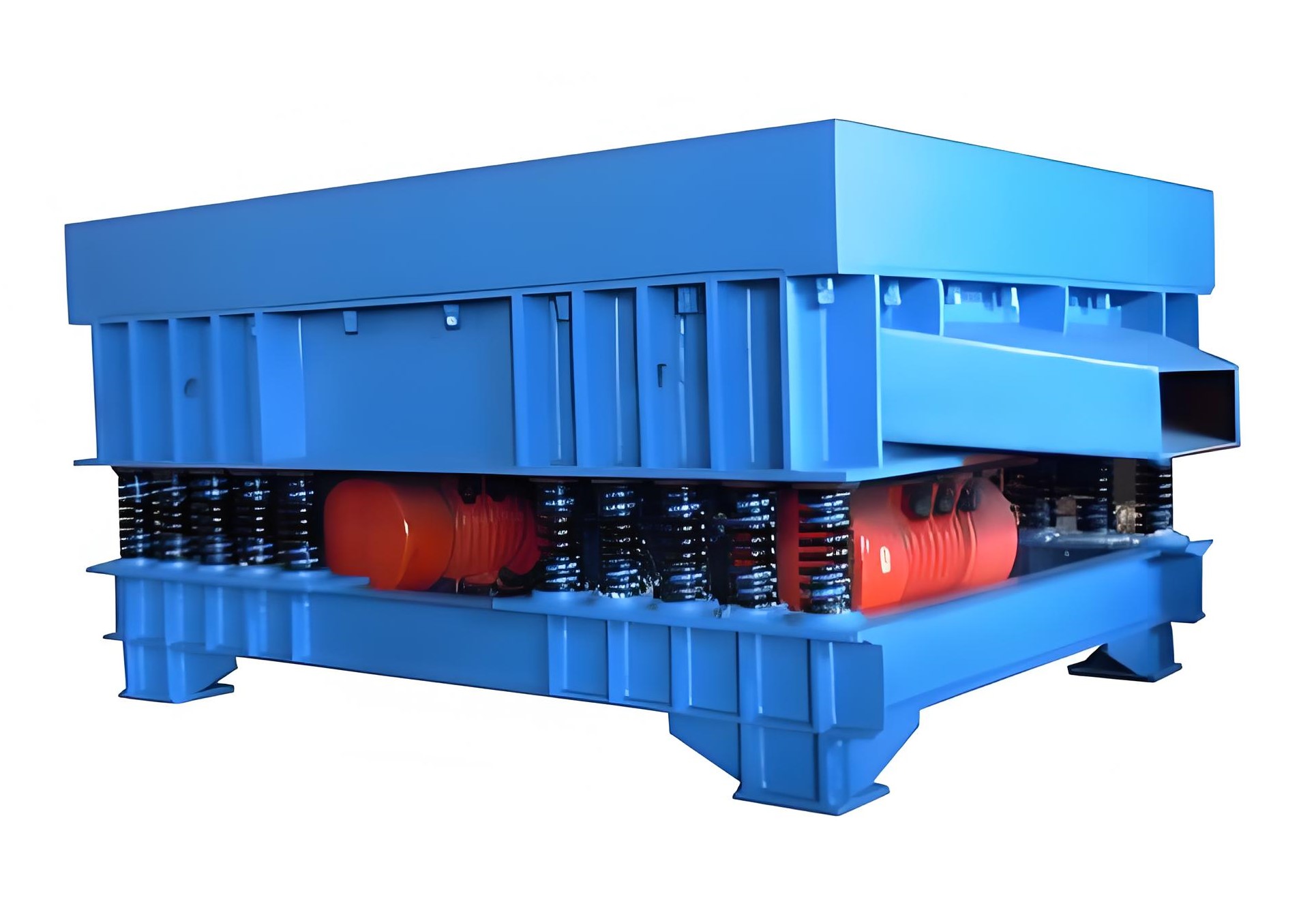

Shakeout machine

- Shakeout table size tailor-made

- Load capacity tailor-made

- Table heat treated after fully welding

- High quality vibration motor

Polygonal sand sieve

- SS304 wire mesh sieve

- 10T – 160T capacity available

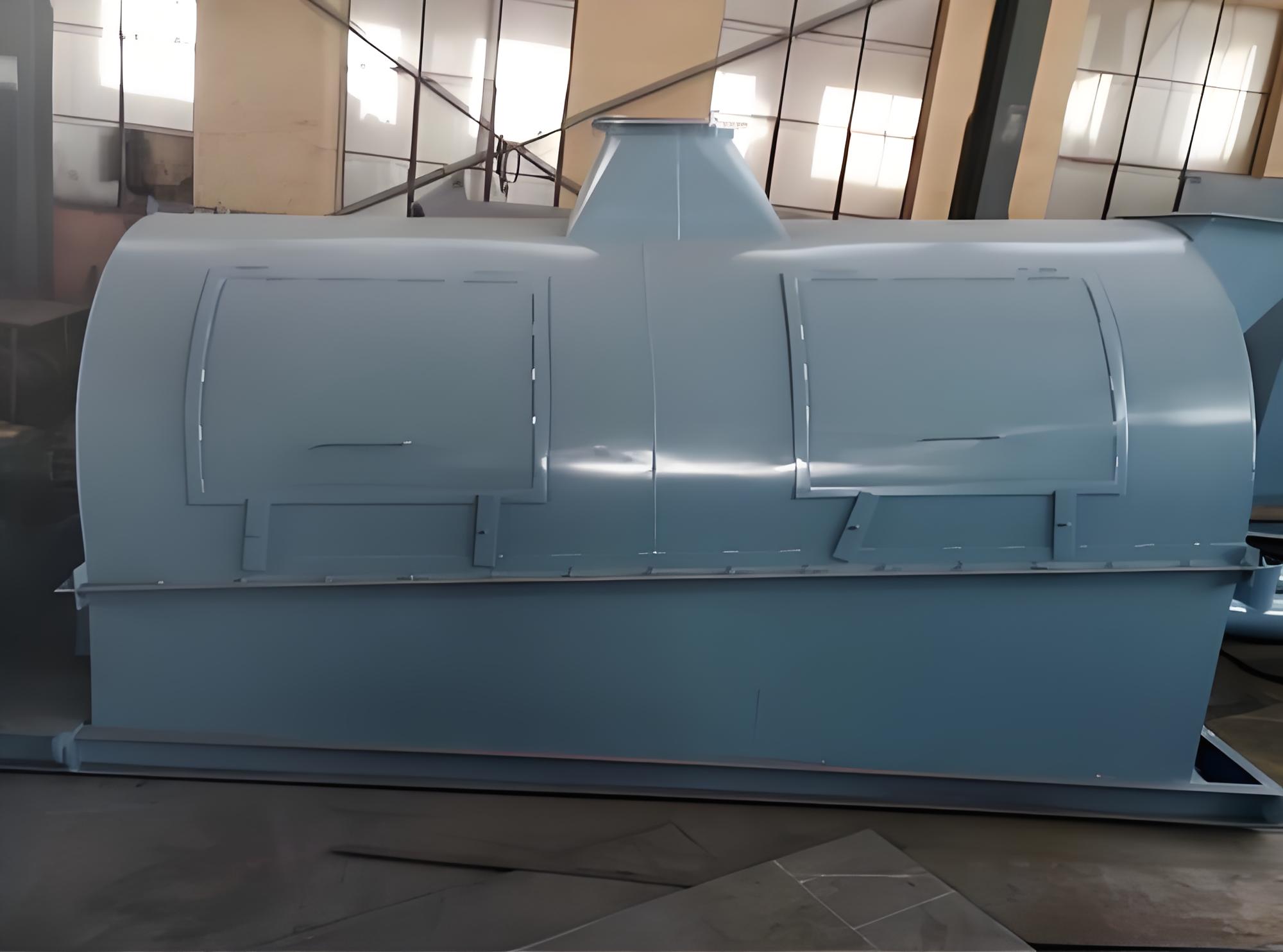

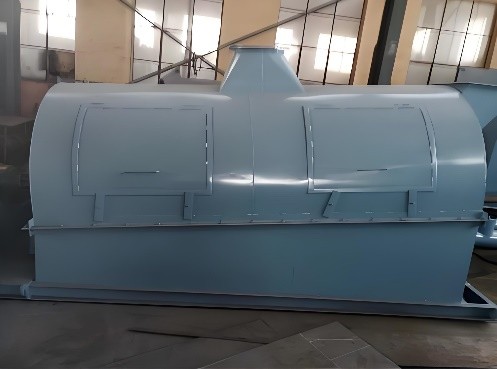

Sand cooler

- High efficiency sand cooling

- 20T/h to 200T/h capacity available

- Can work with online testing system

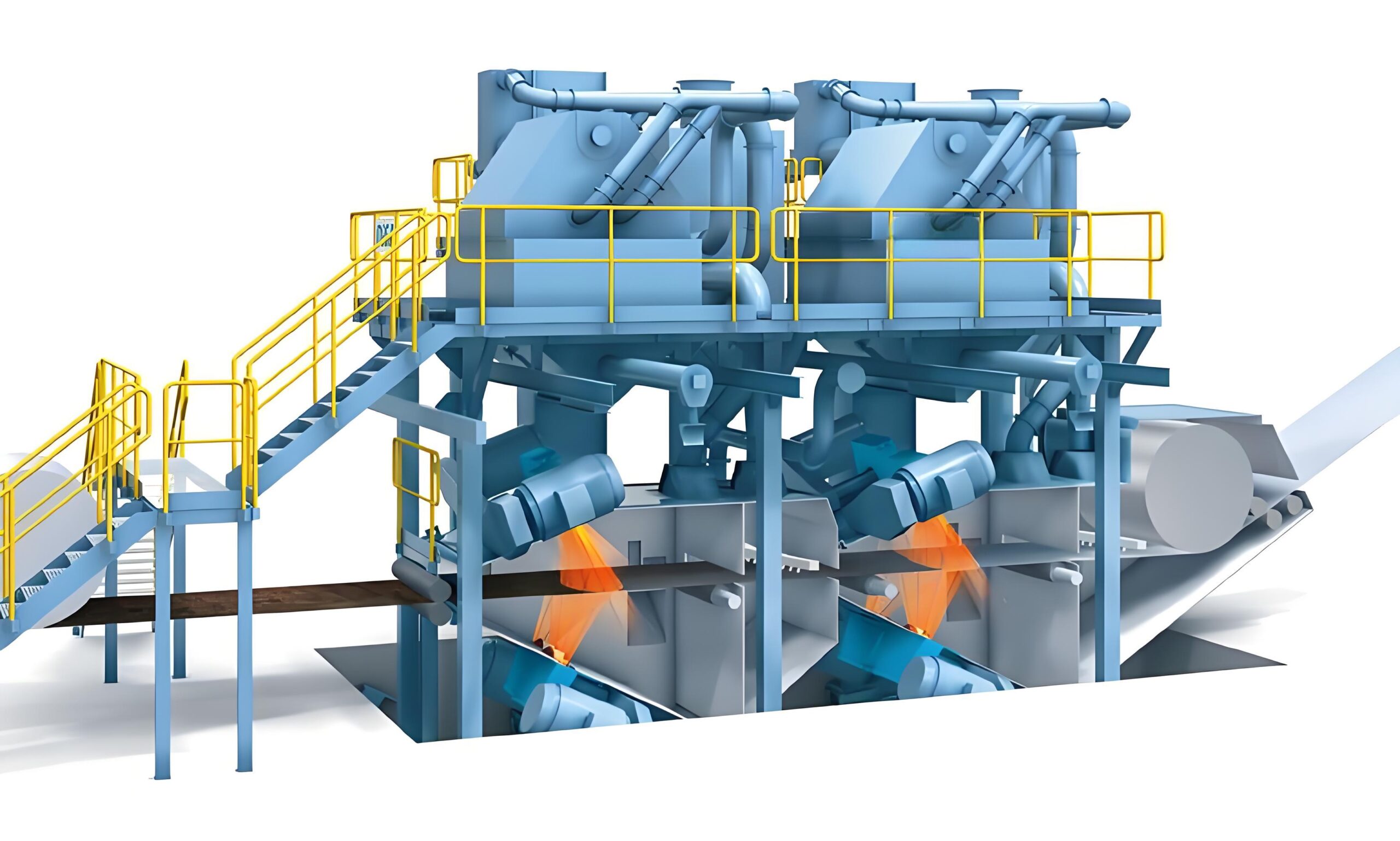

Casting cooling rotary drum

- Normally used for high productivity molding line

- Continuous working

- Casting cooling and sand shaking function