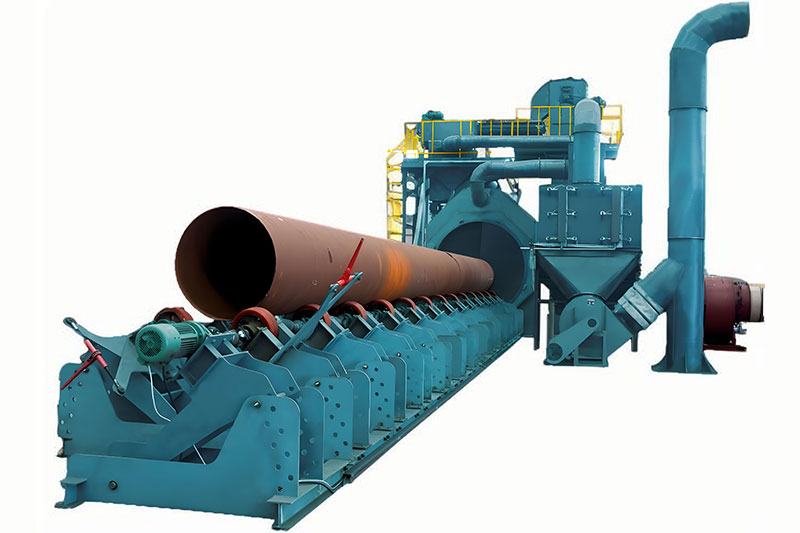

- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

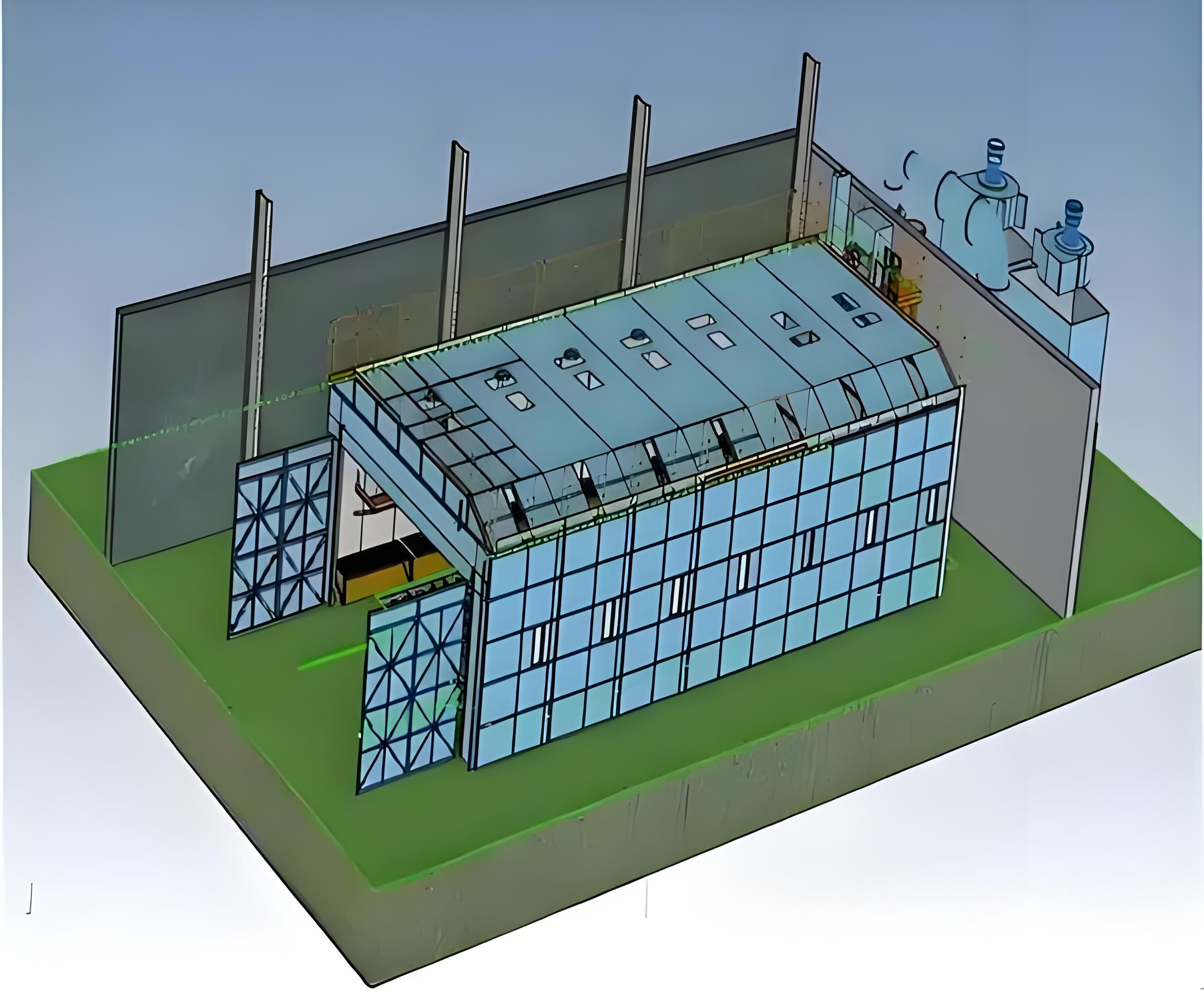

Green Sand Flask Molding Machine

Green Sand Flask Molding Machine

- Automotive Parts: Engine blocks, cylinder heads, brake drums.

- Industrial Components: Manhole covers, pipe fittings, pump housings.

- Agriculture and Construction: Plowshares, gear housings, machinery parts.

- Art and Decorative Castings: Statues, ornamental pieces.

- Prototyping and Low-Volume Production: Ideal for custom or small-batch orders.

Product Parameters

Applications

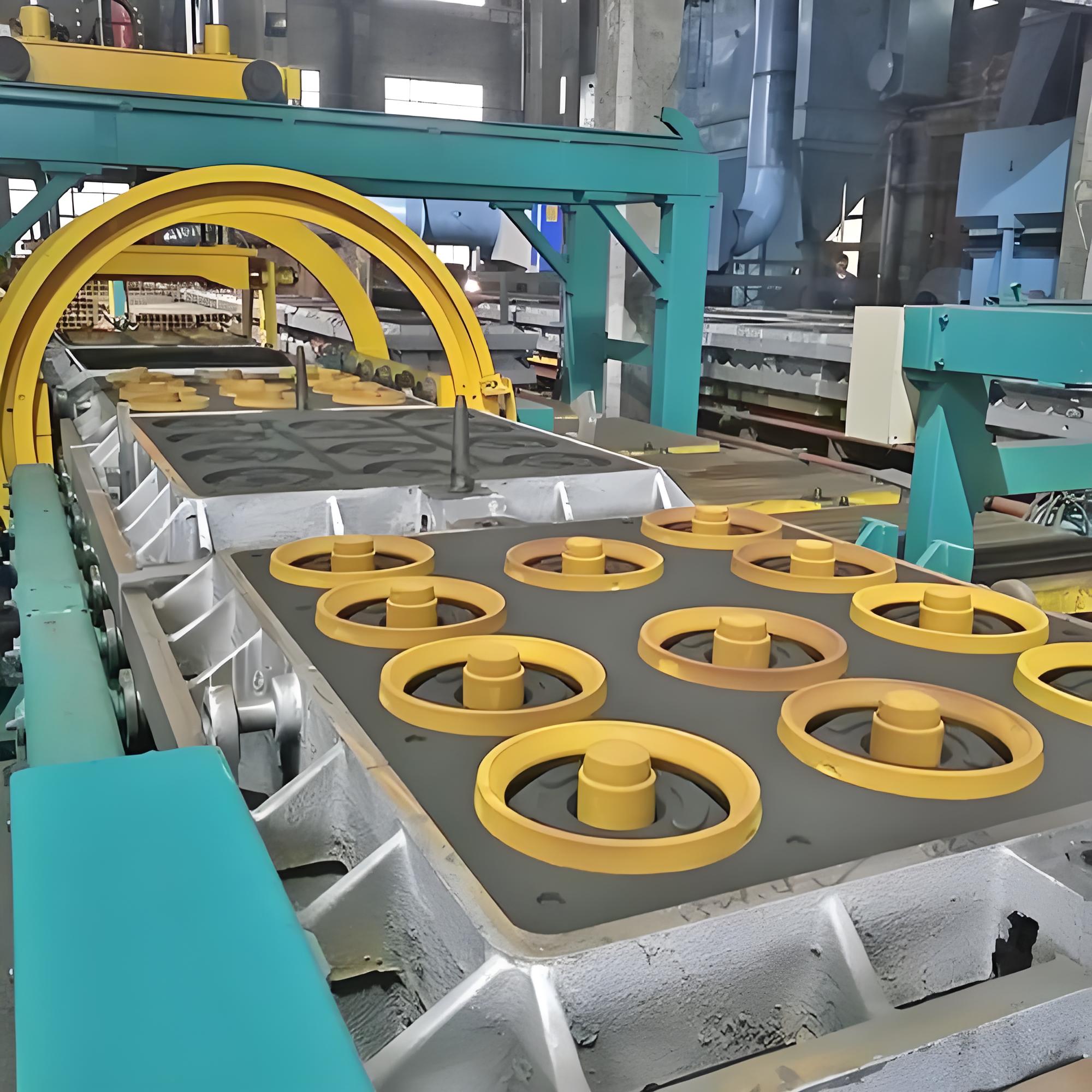

Green Sand Flask Molding is a traditional casting method where molds are created using a mixture of sand, clay, water, and additives (called “green sand”), contained within flasks (metal frames). The term “green” refers to the uncured, moist state of the sand. This process is widely used for its simplicity and versatility, particularly in small to medium-scale foundries.

How It Works:

- Pattern Setup: A reusable pattern (wood, metal, or plastic) is placed in a flask (split into cope and drag halves).

- Sand Compaction: Green sand is packed around the pattern manually or via machines (e.g., jolt-squeeze or vibrating equipment).

- Mold Assembly: The flask is separated, the pattern is removed, and cores (if needed) are inserted. The cope and drag are reassembled to form a complete mold cavity.

- Pouring: Molten metal is poured into the mold.

- Cooling and Shakeout: After solidification, the flask is disassembled, and the casting is removed. The sand is reclaimed and reused.

Applications:

- Automotive Parts: Engine blocks, cylinder heads, brake drums.

- Industrial Components: Manhole covers, pipe fittings, pump housings.

- Agriculture and Construction: Plowshares, gear housings, machinery parts.

- Art and Decorative Castings: Statues, ornamental pieces.

- Prototyping and Low-Volume Production: Ideal for custom or small-batch orders.

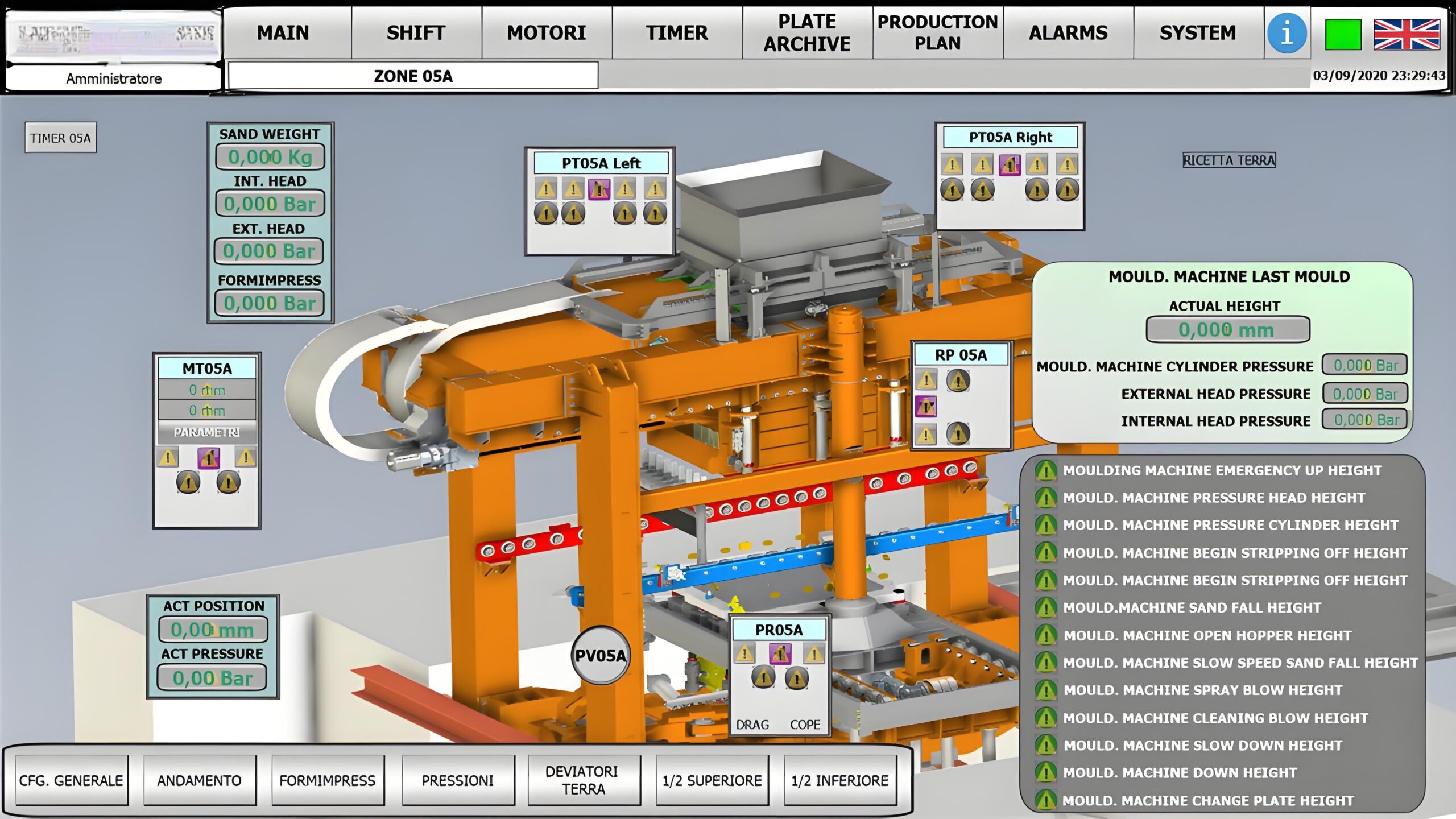

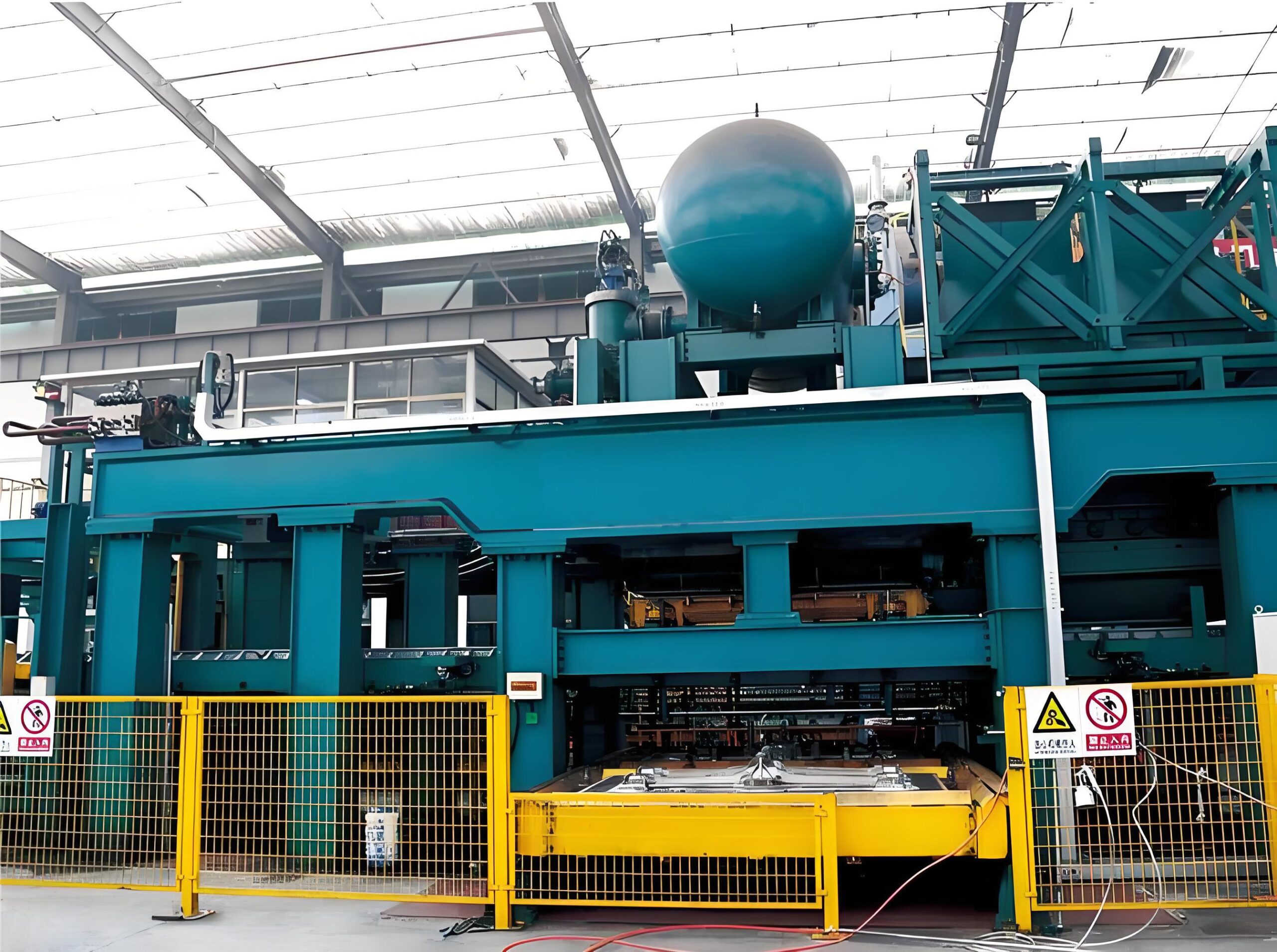

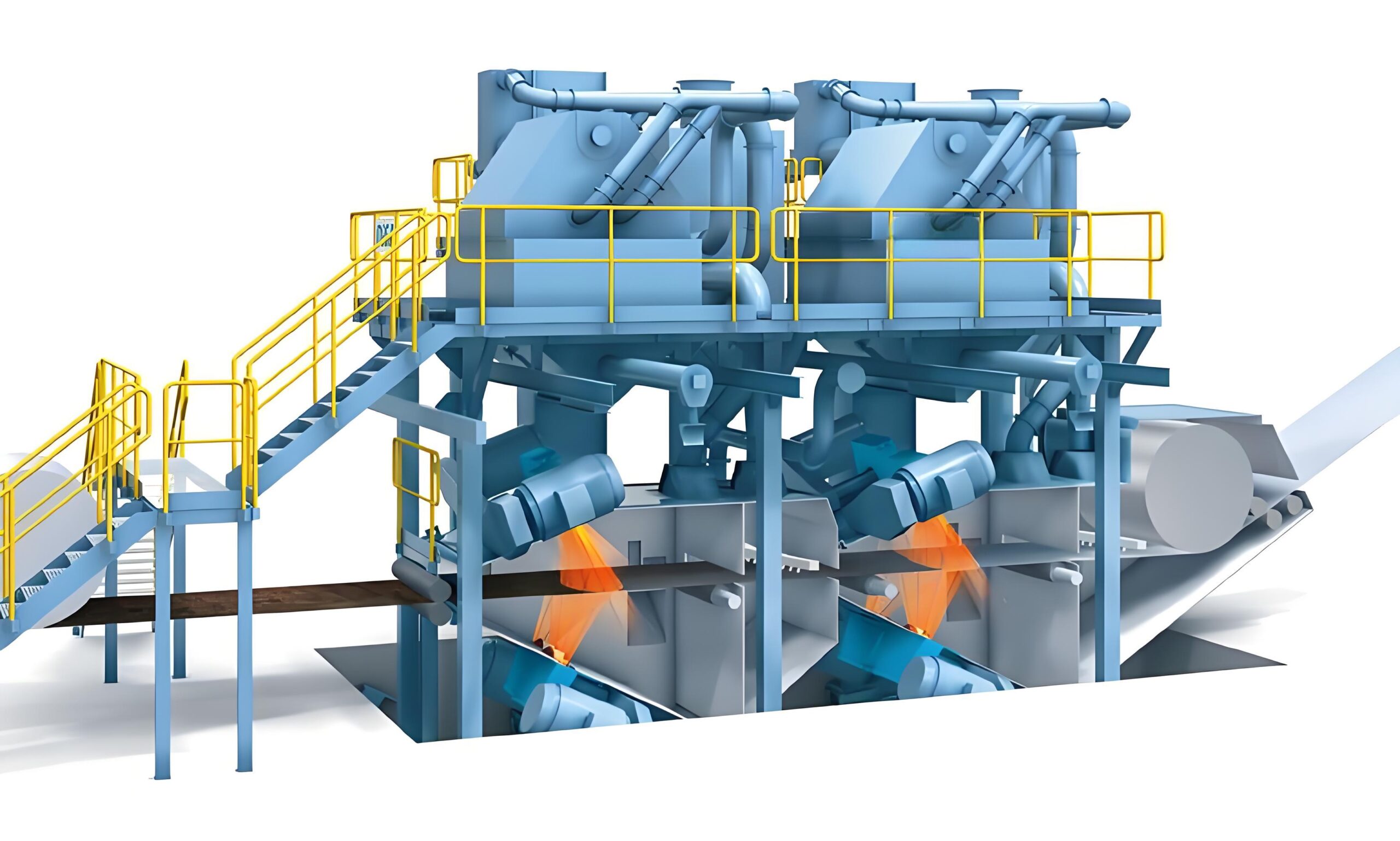

Using air blowing precompaction and multi-contact high-pressure compaction molding technology, high sand mold hardness, compactness uniformity, high box closure precision, high casting precision, high yield. The average hardness of sand mold is 90-95. Hydraulic multi-contact compaction, the compaction ratio can be adjusted in different zones, up to 1.5 Mpa.

The whole line adopts the principle of combining electric, hydraulic and pneumatic transmission, and the key components adopt international brand products to ensure the smooth and reliable operation of the production line.

Main Benefits

Full-line automatic high-efficiency, high casting precision, clean working environment, is the most advanced molding production line. Has been widely used in automotive castings and other gray iron, ductile iron, cast steel and other high-grade casting mass production

Model & Specification

| Parameter/model | FM66 | FMZ77 | FM97 | FM98 | FM108 | FM1010 |

| Flask inner size(mm) | 680x580x200/220 | 700x700x350/250 | 900x700x250/250 | 900x800x350/300 | 1000x800x350/320 | 1000x1000x350/250 |

| productivity(box/h) | 120 | 110 | 100 | 100 | 100 | 100 |

| Parameter/model | FM128 | FM129 | FM138 | FM139 | FM188 | FM19515 |

| Flask inner size(mm) | 1200x800x350/250 | 1200x900x350/350 | 1300X800x300/300 | 1300x900x350/300 | 1850x800X380/320 | 1950x1500x550/450 |

| productivity(box/h) | 100 | 100 | 90 | 90 | 40 | 40 |

We have more models and types of automatic flask molding machine, you can contact and get the Contact Professional Engineer.

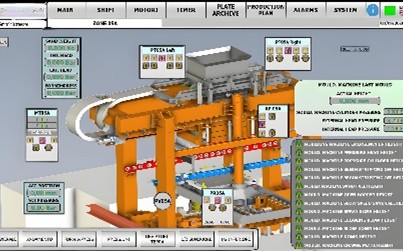

Static molding machine

Tailor made flask size

Flask manipulator

Flask manipulator to handle and close cope and drag

Flask rotate machine

Rotate the flask to make it upside down

Automatic core setting machine

Whole use automatic PLC control and has touch screen for easy operation

Automatic pouring machine

Automatic pouring machine to reduce labor strength and danger.