- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

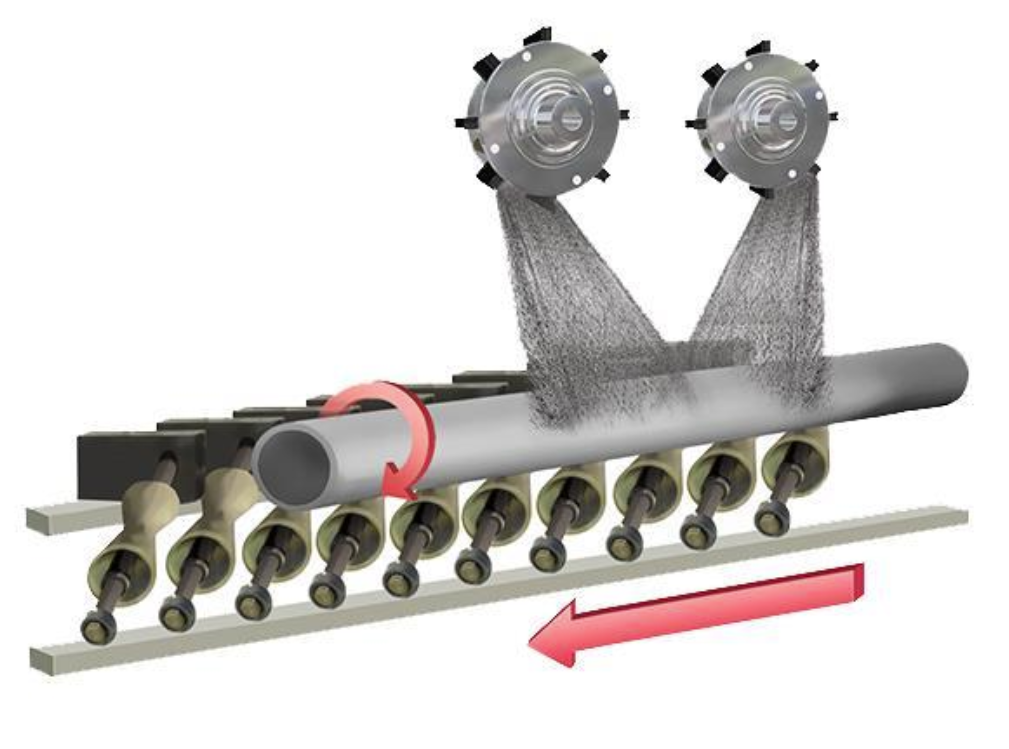

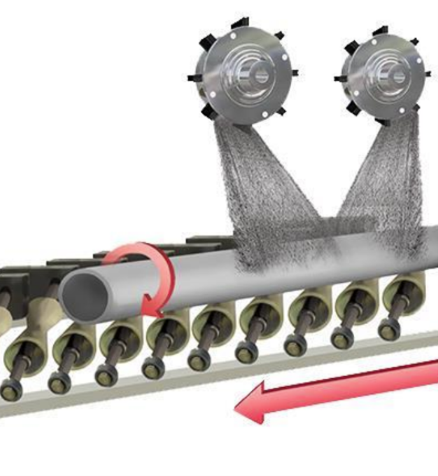

Diabolo roller conveyor type shot blasting machine

Diabolo roller conveyor type shot blasting machine

- High cleaning capacity, short blasting time

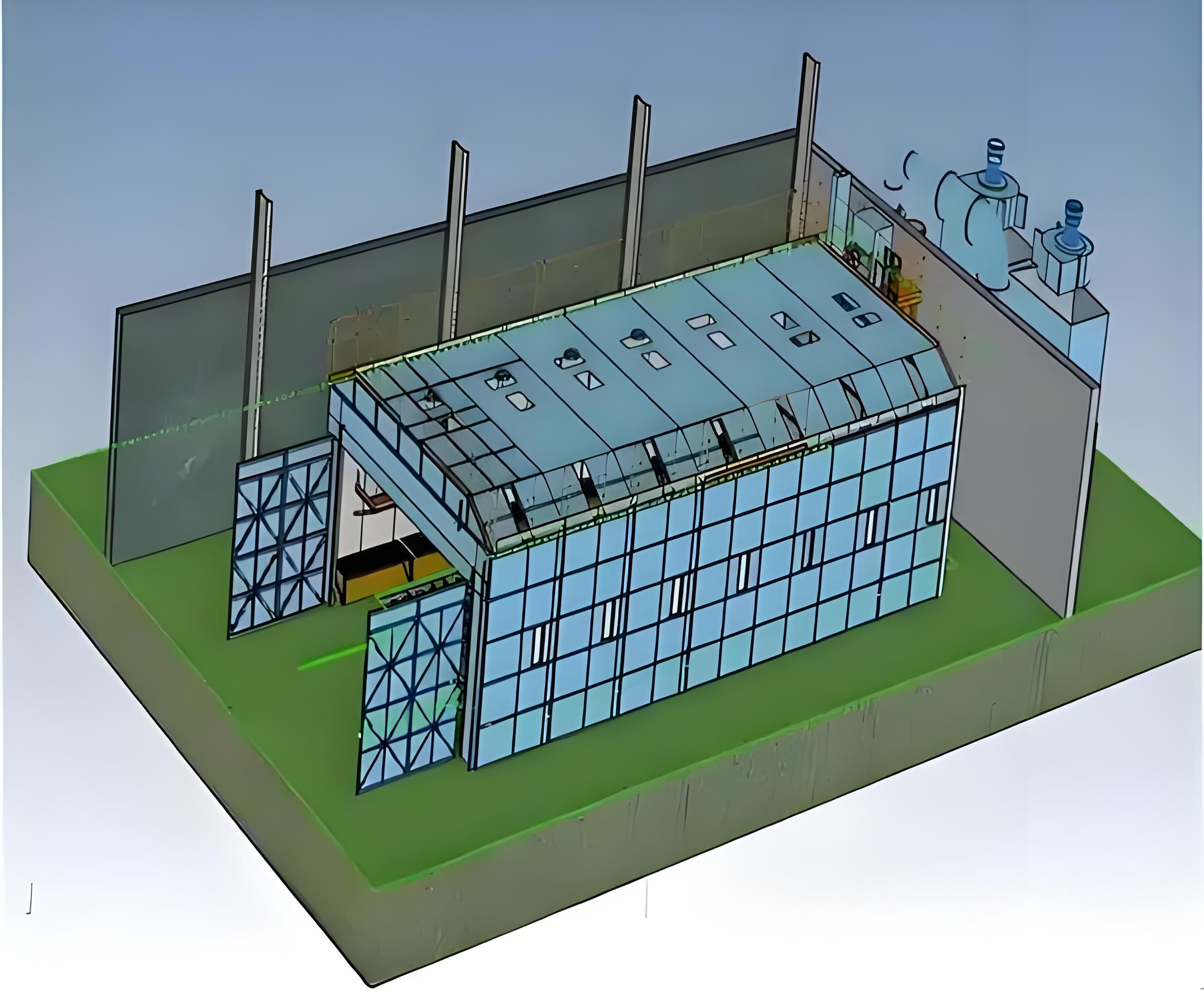

- Entirely automated continuous production work flow

- Integration into existing production line

- Leading technology, outstanding performance

- Available with one, two or more blast wheels, depending on the application and cleaning rate

- Variable speed skew roll conveyor

Quote Now

Product Parameters

Applications

Diabolo blast machines are used in order to scale and to derust tubes, poles, steel cylinders and other round components. Combined with correspondent transversal conveyors several segment such as blasting, conserving, welding and drilling can be linked together. Therefore, a flexible production process and a high material output are ensured.

The part is conveyed through the blast machine on a specially designed skew roll type material handling system.

Main Benefits

- High cleaning capacity, short blasting time

- Entirely automated continuous production work flow

- Integration into existing production line

- Leading technology, outstanding performance

- Available with one, two or more blast wheels, depending on the application and cleaning rate

- Variable speed skew roll conveyor

Model & Specification

| Type | QGW20 | QGW60 | QGW60+ |

| Maxi. Pipes diameter (mm) | 200 | 600 | 600 |

| Work speed (m/min) | 0.5-2 | 0.5-4 | 2-8 |

| Number of blast wheels | 2/3 | 3/4 | 3/4/5/6 |

| Power per blast wheel (kW) | 7.5/11/15/18.5 | 7.5/11/15/18.5 | 7.5/11/15/18.5/22 |

| Alternative pitch (mm) | No | No | No |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

Skew roller conveyor

- The part is conveyed through the blast machine on a specially designed skew roll type material handling system.

- An extensive range of high production blast cabinets are available to handle a wide variety of work sizes at variable cleaning speeds.

High speed blast wheel

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

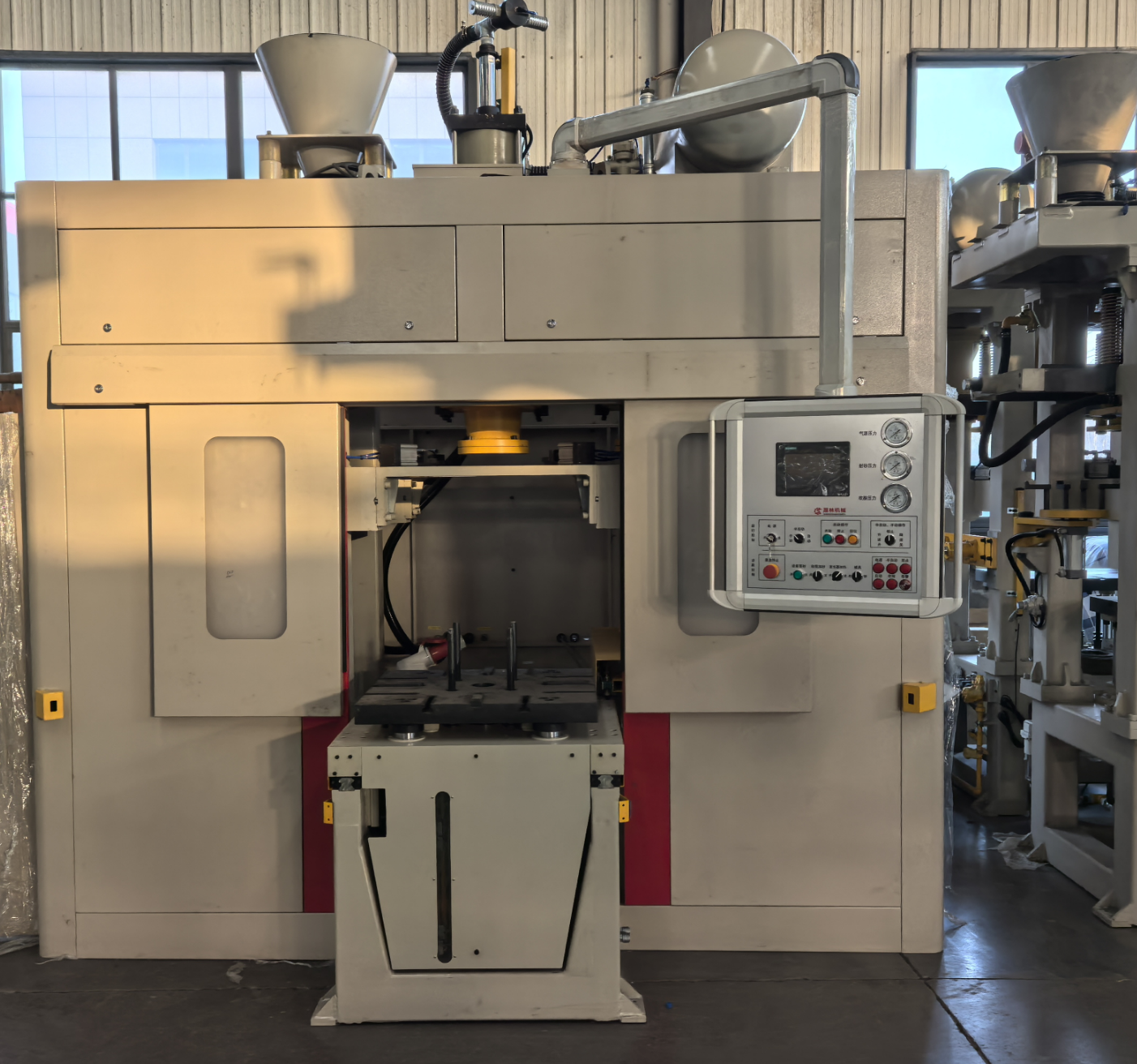

Automatic loading device

- To combine with automatic production line, the automatic loading device is available.