- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

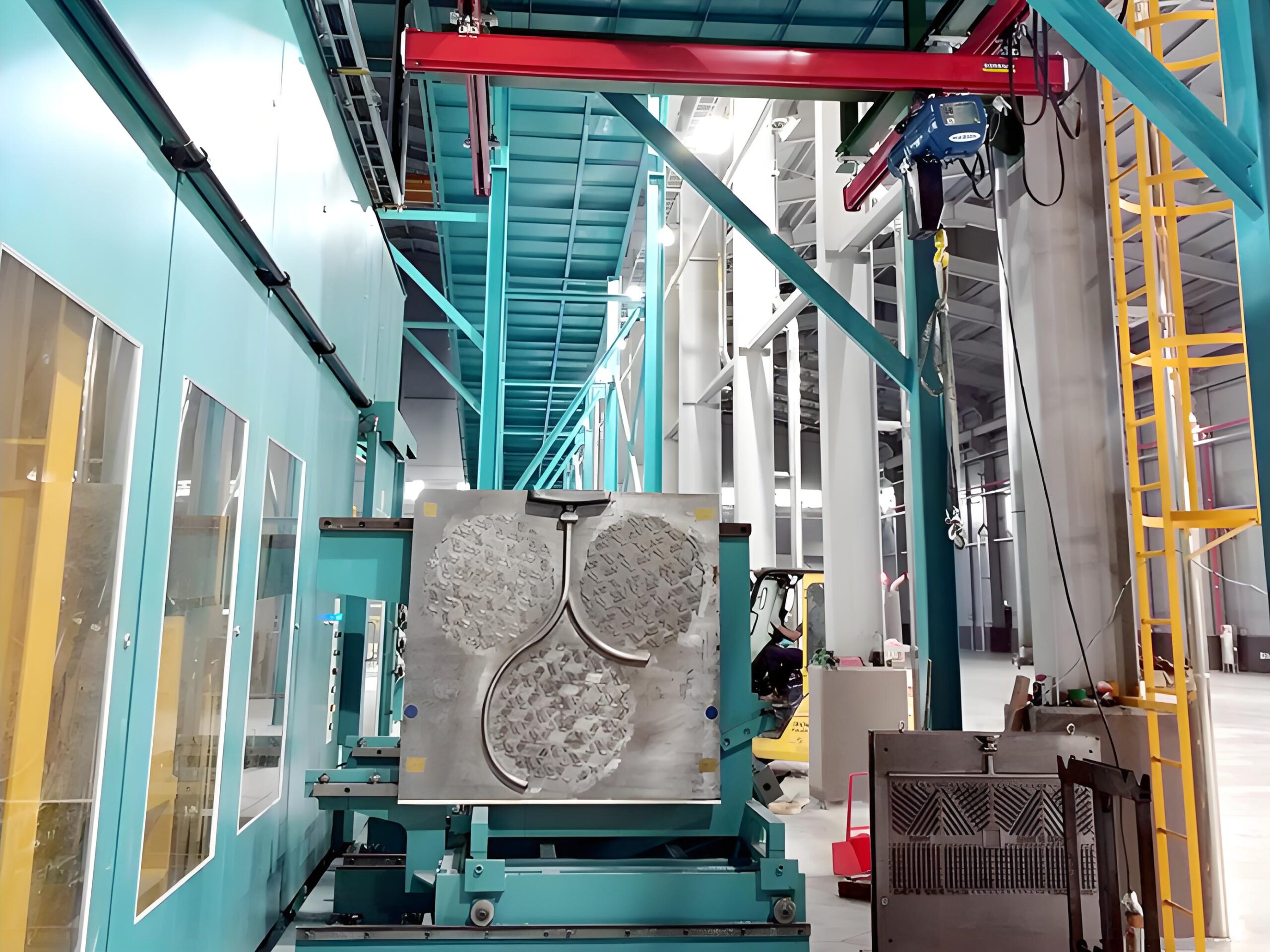

Automatic Vertical Flaskless Molding Machine

Automatic Vertical Flaskless Molding Machine

- Efficiency: Faster cycle times due to automation and vertical stacking.

- Cost Savings: Eliminates flask costs and reduces labor and storage needs.

- Quality: Vertical pouring minimizes turbulence, reducing defects like porosity.

- Sustainability: Less sand waste and energy consumption; recyclable sand.

- Precision: High-pressure compaction ensures consistent mold integrity and surface finish.

Quote Now

Product Parameters

Applications

The vertical flaskless molding Line is a vertical, greensand moulding system capable of producing a wide range of grey iron, ductile iron and other metal castings in various sizes.

How It Works:

- Sand Preparation: Sand mixed with binders is compacted vertically between two patterns using hydraulic or pneumatic pressure.

- Mold Formation: The compacted sand forms a rigid mold without flasks, held together by mechanical force or binders.

- Pouring: Molten metal is poured into the vertical mold, leveraging gravity for efficient filling and solidification.

- Cooling and Extraction: After cooling, the mold is disassembled, and the casting is removed, with sand often recycled.

Applications:

- High-Volume Parts: Ideal for automotive components (brake discs, engine blocks), pump housings, and agricultural machinery parts.

- Symmetrical/Medium-Sized Castings: Suitable for gears, manifolds, and HVAC components.

- Industries: Widely used in automotive, aerospace (certain precision parts), and industrial machinery sectors.

Main Benefits

- Efficiency: Faster cycle times due to automation and vertical stacking.

- Cost Savings: Eliminates flask costs and reduces labor and storage needs.

- Quality: Vertical pouring minimizes turbulence, reducing defects like porosity.

- Sustainability: Less sand waste and energy consumption; recyclable sand.

- Precision: High-pressure compaction ensures consistent mold integrity and surface finish.

Model & Specification

| mold | ZZ416AF | ZZ416BF | ZZ417AF | ZZ417BF | ZZ417CF | ZZ417DF | ZZ418YF | ZZ418AF | ZZ418BF/BD | |

| sand mold size | width(mm) | 600 | 650 | 700 | 750 | 700 | 750 | 800 | 800 | 850 |

| height(mm) | 480 | 535 | 535 | 535 | 600 | 600 | 600 | 600 | 650 | |

| thickness(mm) | 130~390 | 130~390 | 130~390 | 130~390 | 130~390 | 130~390 | 130~380 | 150~500 | 150~500 | |

| mold speed M/H | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 350 | 350 | |

| mold | ZZ419AF | ZZ419BF | ZZ419XF | ZZ419YF | ZZ4110AF | ZZ4110BF | ZZ4111AF | ZZ4112AF | ZZ4113AF | |

| sand mold size | width(mm) | 900 | 900 | 950 | 950 | 1000 | 1000 | 1100 | 1200 | 1300 |

| height(mm) | 650 | 700 | 700 | 800 | 800 | 900 | 1050 | 1100 | 1100 | |

| thickness(mm) | 150~500 | 150~500 | 200~650 | 200~650 | 200~650 | 200~400 | 200~350 | 250~350 | 250~500 | |

| mold speed M/H | 330 | 330 | 280 | 280 | 280 | 200 | 200 | 200 | 200 | |

We have more models and types of automatic flaskless molding machine, you can contact and get the Contact Professional Engineer.

Feature

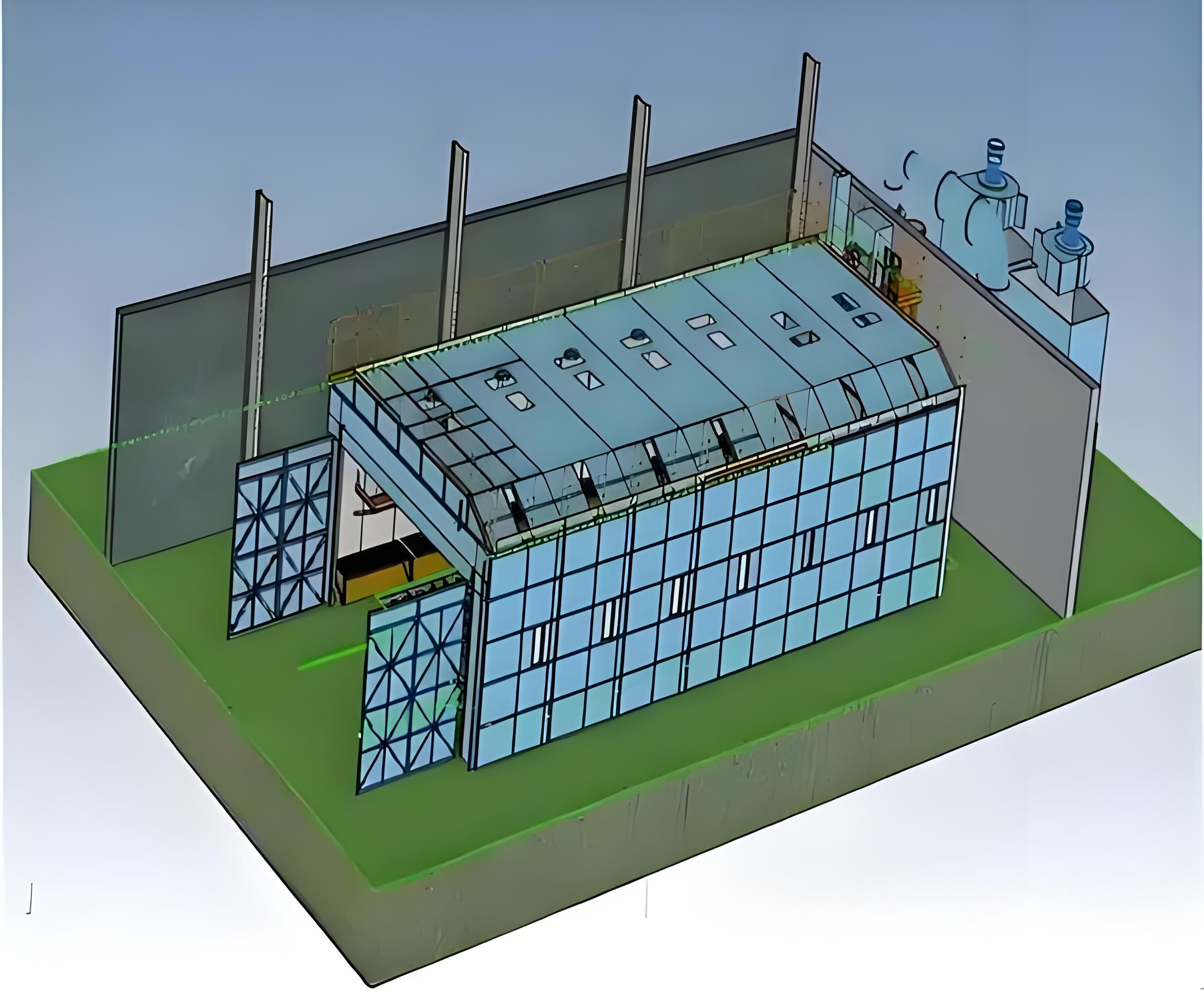

Vertical molding machine

- High speed vertical molding machine

Automatic core setting machine

- For the castings which need cores, an automatic core setting machine is ideal for the line

Sand mould clamping conveyor

- can effectively improve the conveying accuracy of large sand mold and reduce equipment wear.

Quick mold change device

- The line can have quick mold change device to meet high working efficiency.

PLC Control system

- SIEMENS Automatic control

Automatic pouring machine

- Automatic pouring machine to reduce labor strength and danger.