- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Resin Sand Preparation Line

Resin Sand Preparation Line

- Consistent & High-Quality Sand Mixture:

- Uniform Distribution: Ensures every sand grain is evenly coated with the precise amount of resin and catalyst.

- Optimal Properties: Delivers sand with repeatable flowability, compactability, strength (green & cured), and collapsibility.

- Reduced Variability: Eliminates human error inherent in manual or batch mixing processes.

- Result: Higher dimensional accuracy and surface finish of castings, fewer defects (veins, fins, blows, poor surface), lower scrap rates.

- Increased Production Efficiency & Speed:

- Continuous Operation: Produces bonded sand non-stop, feeding molding/core machines seamlessly.

- Fast Mixing: High-speed mixers coat sand in seconds

Quote Now

Product Parameters

Applications

Resin sand molds and cores are essential for producing high-quality, complex metal castings across many industries:

- Automotive: Engine blocks, cylinder heads, transmission cases, brake calipers, turbocharger housings.

- Heavy Machinery/Truck: Axle housings, gearboxes, hydraulic components, pump bodies, valve bodies.

- Industrial Valves & Pumps: Complex impellers, valve bodies, casings requiring high precision.

- Agriculture & Construction: Gearboxes, differential housings, hydraulic components, structural parts.

- Railway: Brake system components, couplers, gear housings.

- Aerospace (High-Performance Alloys): Turbine housings, structural components.

- Pipe Fittings & Plumbing: Complex valve bodies and fittings.

Advantages Driving Application:

- High Dimensional Accuracy & Surface Finish: Enables casting intricate shapes with fine details.

- Good Collapsibility: Allows the sand to break away easily from the cooled casting.

- High Strength: Holds complex shapes and withstands the pressure of molten metal.

- Fast Curing: Increased production speed compared to some other binders.

- Good Core/Mold Stability: Less prone to distortion or damage during handling

Main Benefits

The main benefits of a Resin Sand Preparation Line stem from its automation, precision, and consistency, directly translating to improved casting quality, operational efficiency, and cost savings in a foundry. Here are the key advantages:

- Consistent & High-Quality Sand Mixture:

- Uniform Distribution: Ensures every sand grain is evenly coated with the precise amount of resin and catalyst.

- Optimal Properties: Delivers sand with repeatable flowability, compactability, strength (green & cured), and collapsibility.

- Reduced Variability: Eliminates human error inherent in manual or batch mixing processes.

- Result: Higher dimensional accuracy and surface finish of castings, fewer defects (veins, fins, blows, poor surface), lower scrap rates.

- Increased Production Efficiency & Speed:

- Continuous Operation: Produces bonded sand non-stop, feeding molding/core machines seamlessly.

- Fast Mixing: High-speed mixers coat sand in seconds

- Consistent & High-Quality Sand Mixture:

Feature

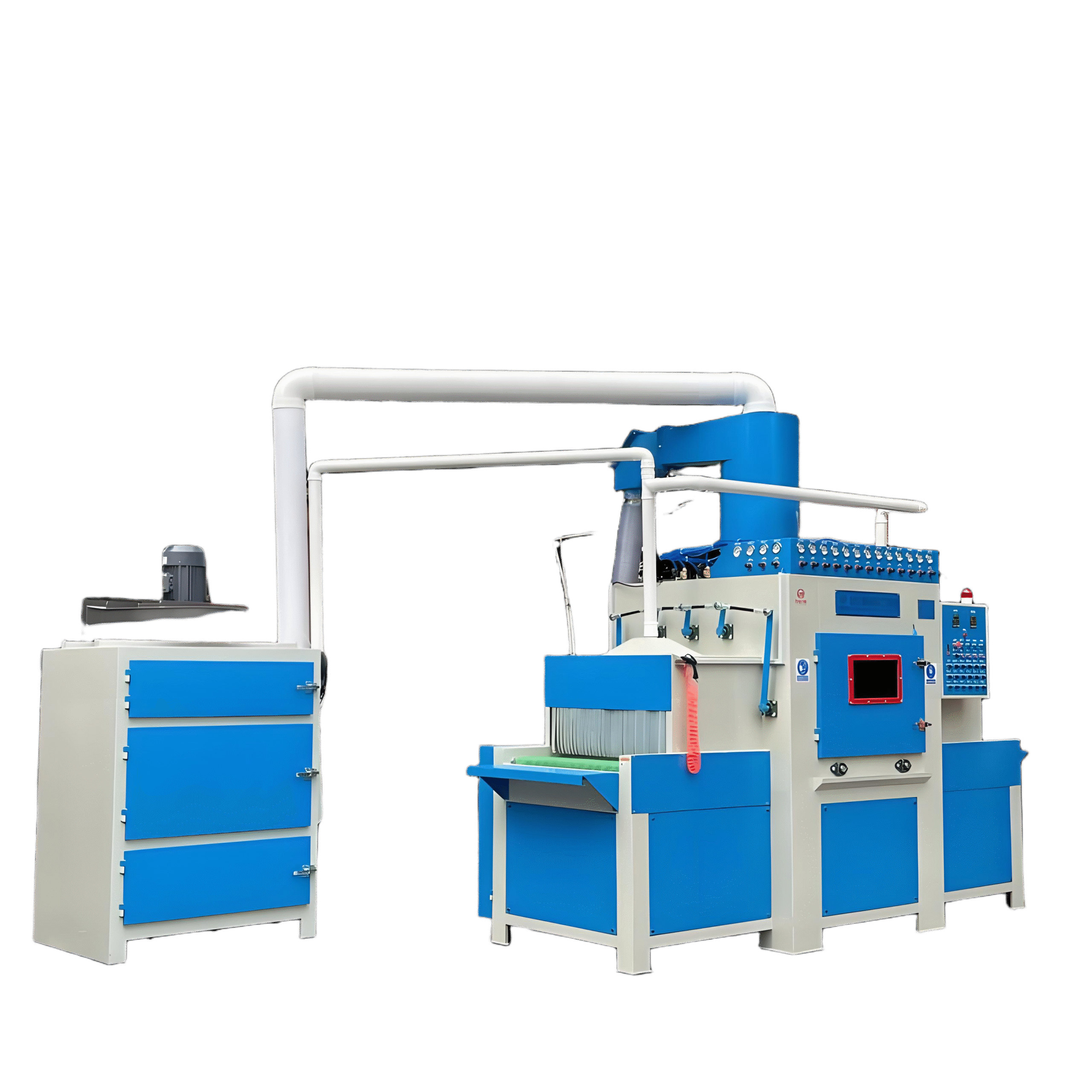

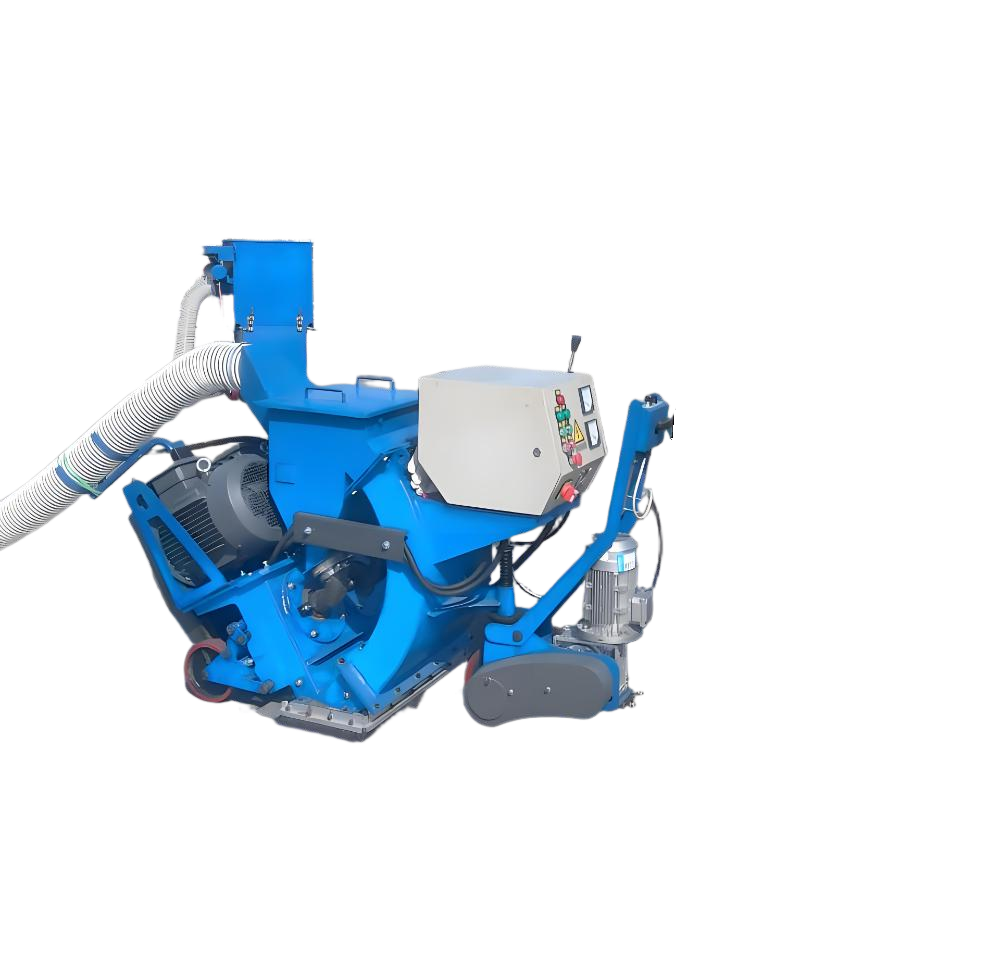

Continuous Sand Mixer

- Capacity from 3T to 30T

- Single arm or Double arm

- Stationary or movable type

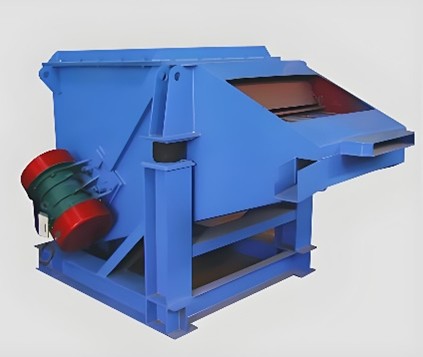

Vibration Molding Table

- Two vibration motor

- Tailor made table size

- Tailor made load capacity

Roller Conveyor

- Heavy duty roller conveyor

- Famous brand bearings

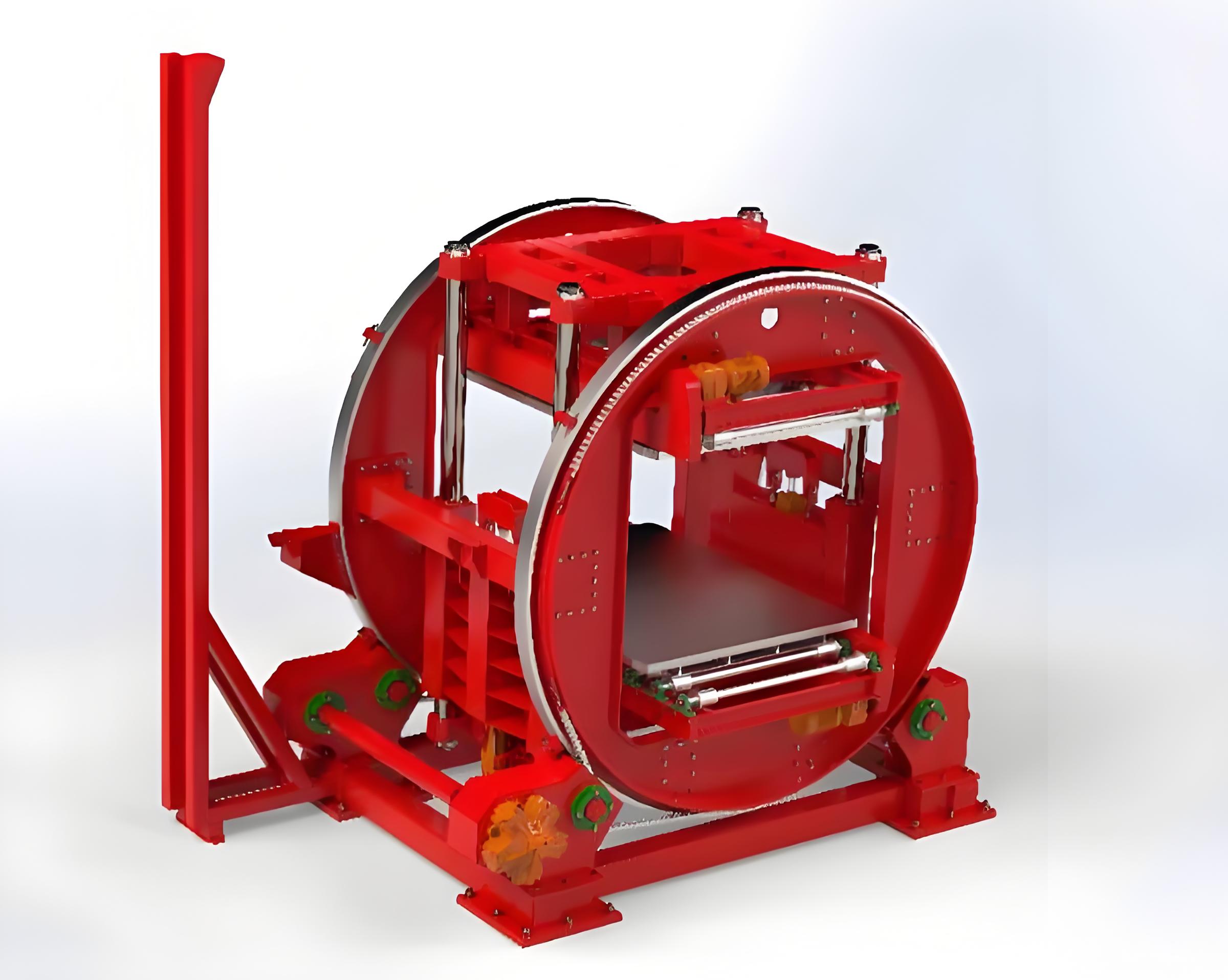

Sand Mould Turnover Machine

- After molding to turn over the mould

- Stable and reliable performance

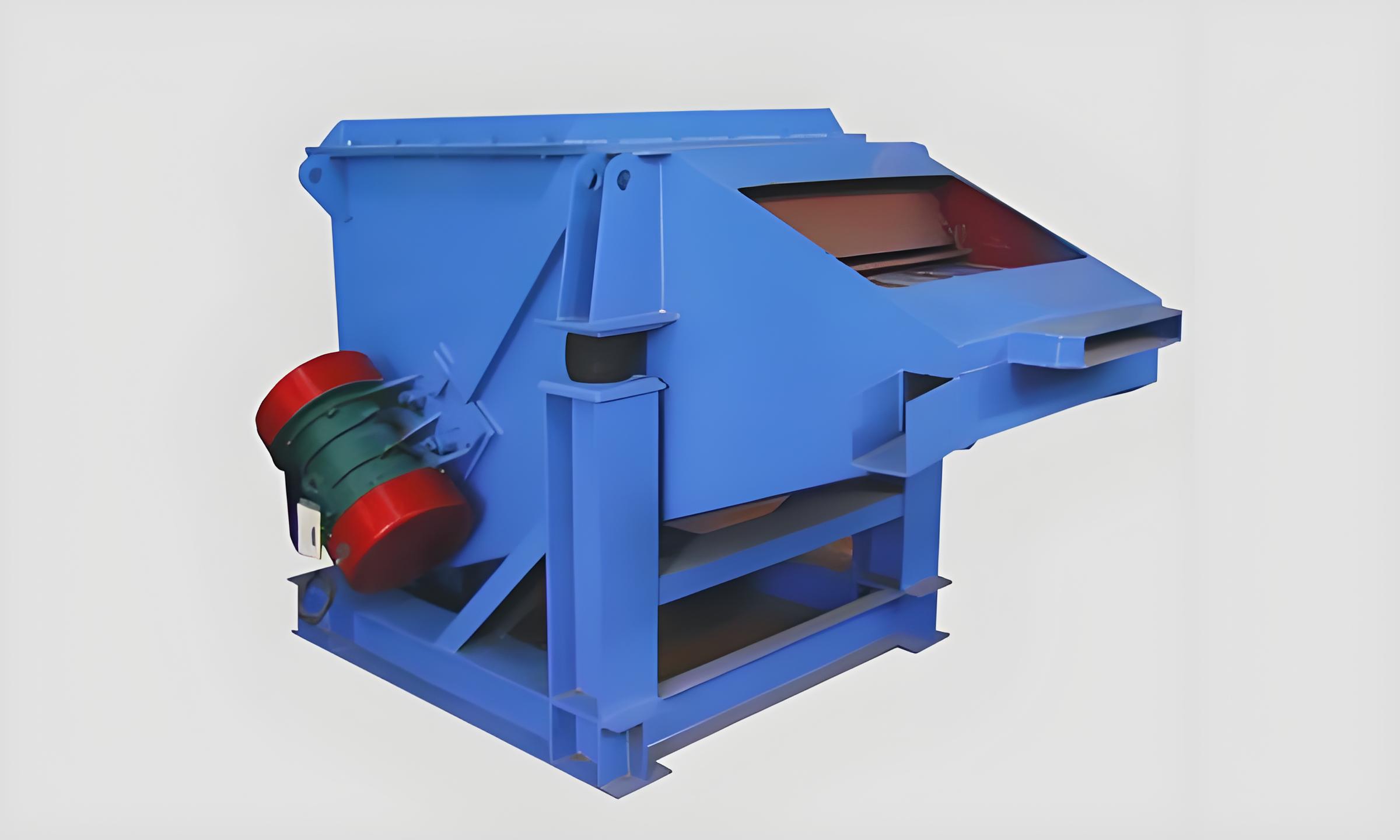

Sand Reclamation Machine

- To regenerate the sand mechanically

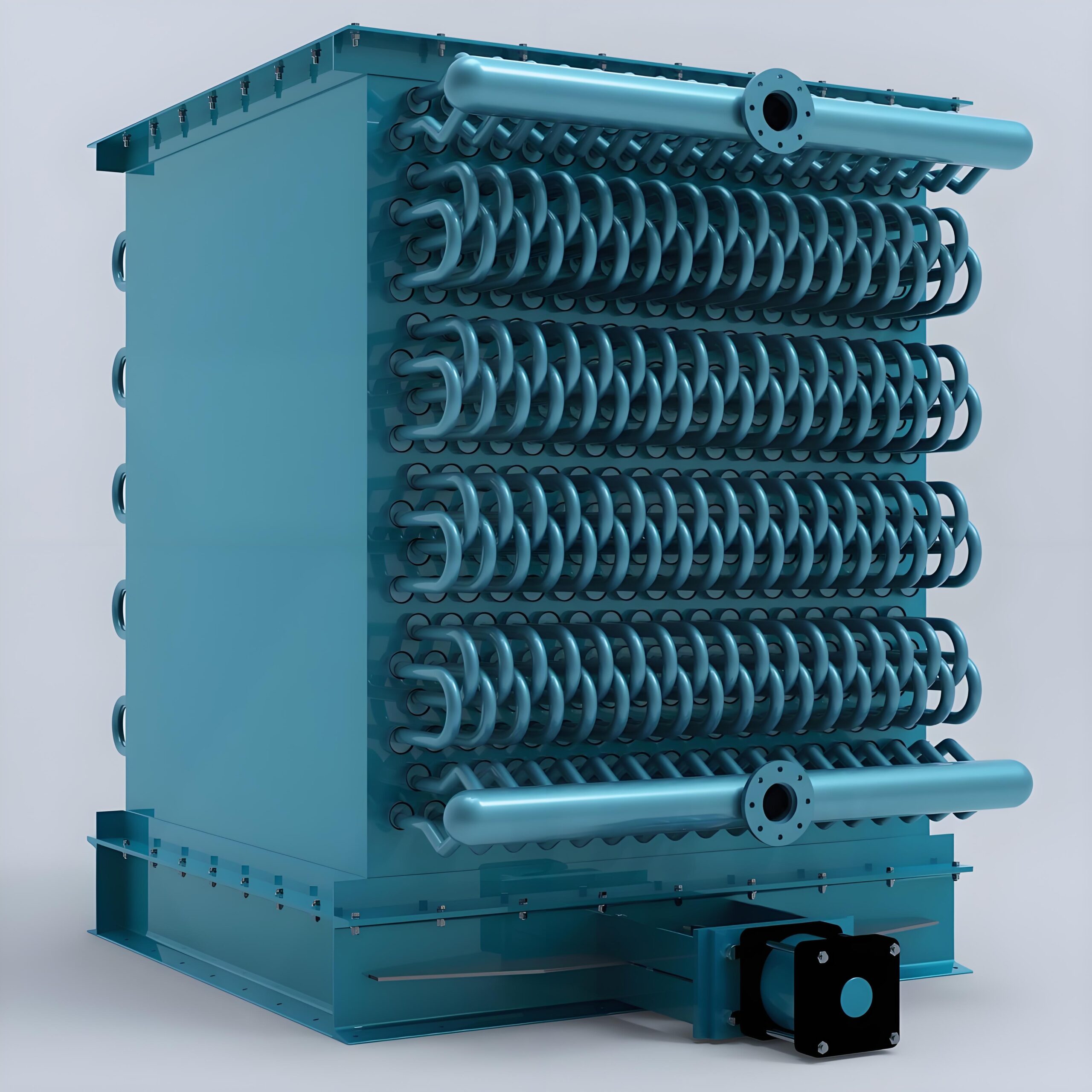

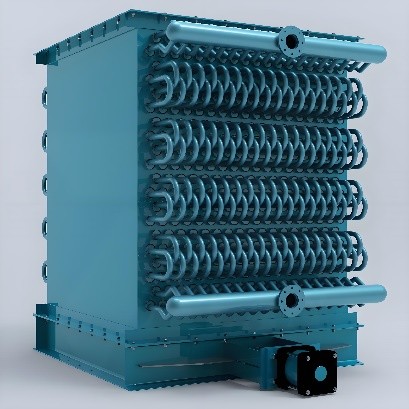

Sand cooler

- Multi water cooling pipe

- to reduce sand temperature