Oversight of sand blast rooms core configs causes inefficiency; mastering key points ensures value for money.

This guide highlights core configurations to ignore when purchasing sand blast rooms, ensuring stable blast sand operations and long-term usability.

Explore key unignorable configurations for high-quality sand blast rooms below.

Why Is the Dust Removal System a Core Configuration for Sand Blast Rooms?

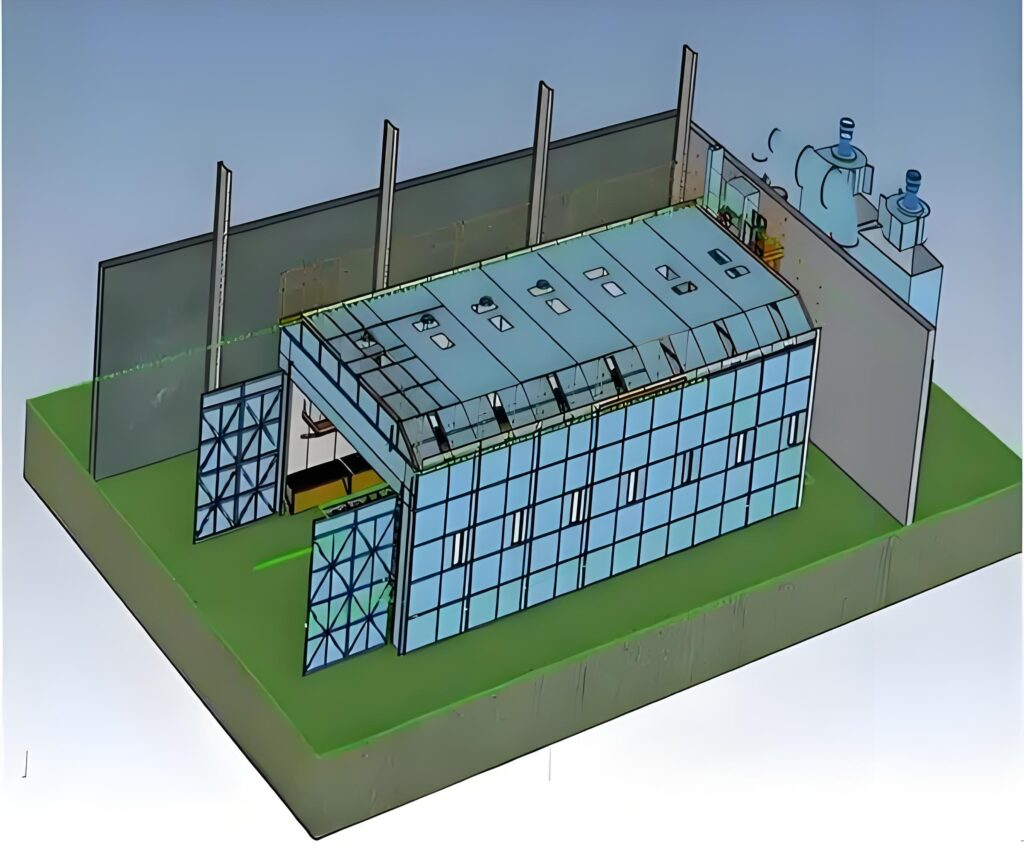

The dust removal system is an indispensable core configuration for sand blast rooms, directly affecting operation safety and environmental compliance. During blast sand operations, a large amount of dust is generated, which not only endangers workers’ respiratory health but also pollutes the surrounding environment and corrodes equipment components. High-quality sand blast rooms must be equipped with a two-stage dust removal system: cyclone separators first capture large blast sand particles for recycling, while HEPA filters trap fine dust (PM2.5 and below), achieving over 99% dust removal efficiency. A reliable dust removal system also prevents dust accumulation in the room, avoiding blockages in blast sand pipelines and extending the service life of the equipment. Ignoring this configuration will lead to frequent shutdowns for dust cleaning, increased operational costs, and even failure to meet environmental emission standards.

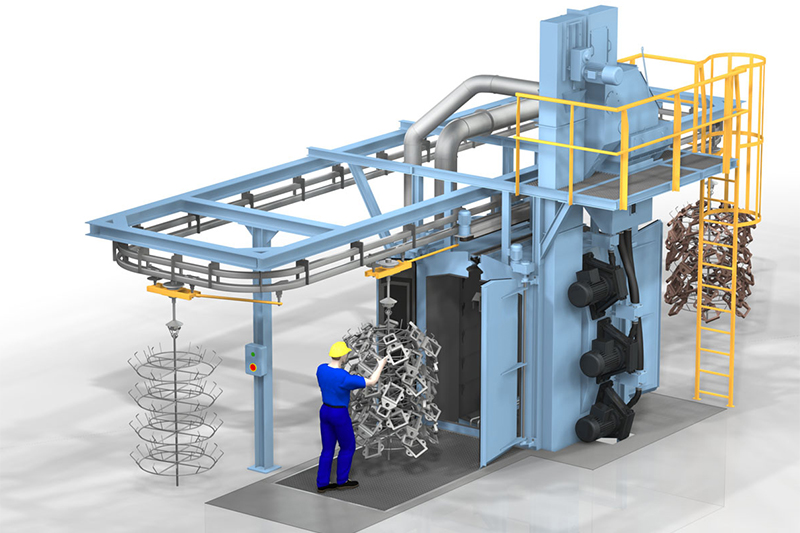

What Are the Requirements for the Abrasive Recovery System in Sand Blast Rooms?

The abrasive recovery system is another core configuration that cannot be ignored when purchasing sand blast rooms, as it directly affects operational efficiency and cost control. During blast sand operations, a large amount of abrasive is used, and an efficient recovery system can recycle 80-90% of the usable blast sand, significantly reducing abrasive procurement costs. High-quality sand blast rooms adopt a closed-loop recovery structure: the floor is designed with a slope to guide blast sand to the recovery port, and a screw conveyor or vacuum suction device transports the abrasive to the screening device, filtering out debris and worn particles before reuse. A well-designed recovery system also reduces manual labor for abrasive cleaning and refilling, improving the continuous operation capacity of the sand blast rooms and ensuring stable blast sand intensity during operations.

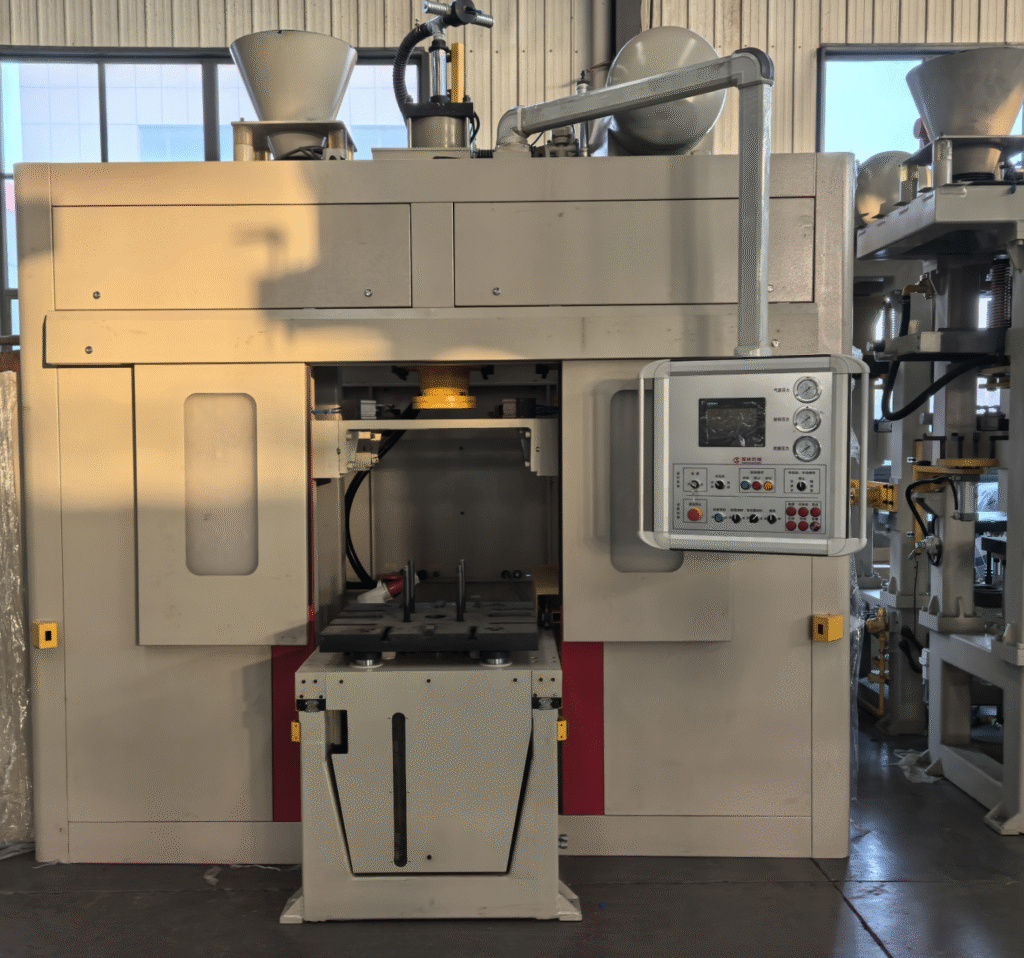

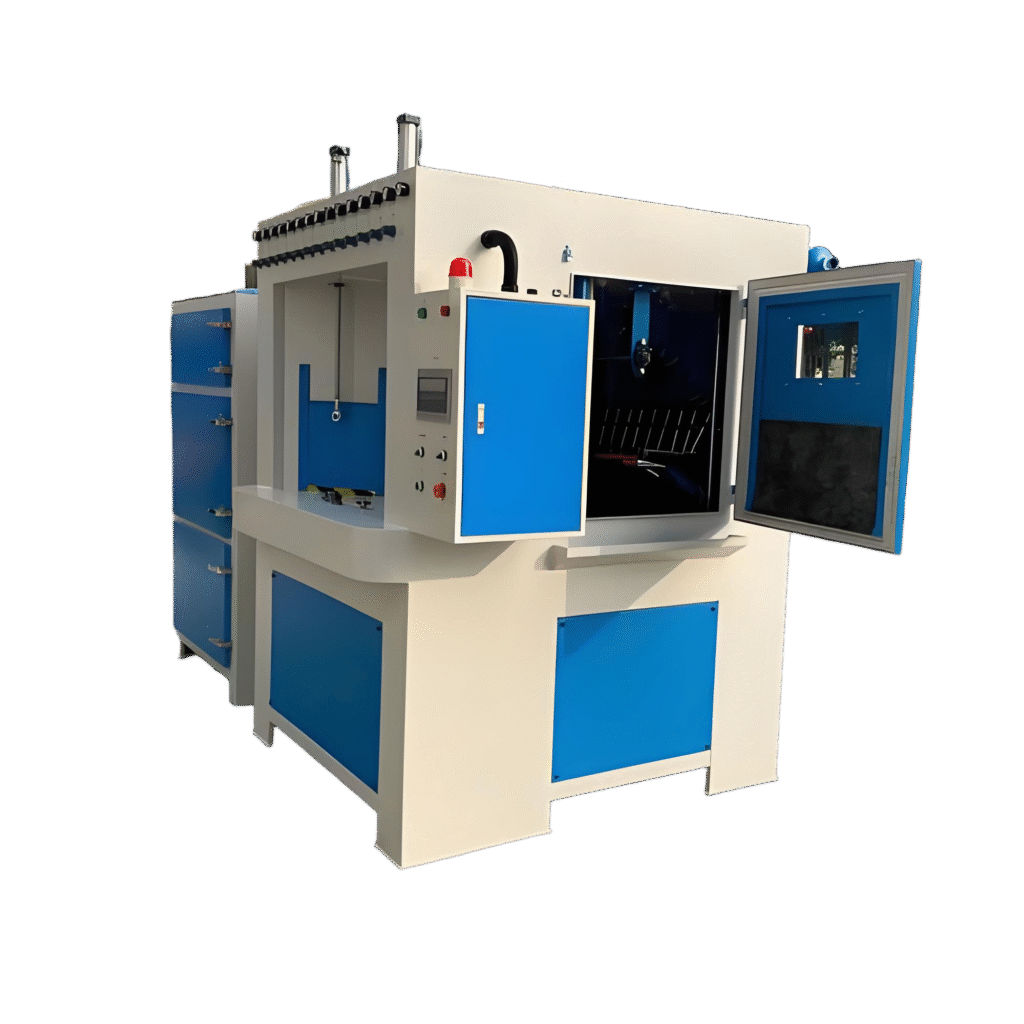

Why Is the Room Body Sealing and Wear Resistance Configuration Important?

Room body sealing and wear resistance are core configurations that determine the service life and operational stability of sand blast rooms. During blast sand operations, high-speed blast sand particles will impact the inner wall of the room, and poor wear resistance will lead to rapid damage to the room body, requiring frequent maintenance or replacement. High-quality sand blast rooms use wear-resistant polyurethane or rubber lining plates on the inner wall, which can effectively resist the impact of blast sand and extend the service life of the room body. Good sealing performance is also crucial: the door seams, pipeline connections, and observation windows of the sand blast rooms must be tightly sealed to prevent blast sand leakage and dust overflow. Poor sealing will not only waste abrasive but also pollute the workshop environment and affect the health of workers outside the room.

Conclusion

Dust removal, abrasive recovery and sealing are unignorable for sand blast rooms.

For professional advice on sand blast rooms purchase and core configuration selection,

contact us via email: [email protected]