Poor shot blasting machine selection causes flawed processing. It leads to high costs and delayed production. This article offers a professional guide for scientific choices.

This Shot Blasting Machine Selection Guide covers mainstream models, core performance comparison, industrial scenario adaptation, key parameters, pitfalls, and cost – compliance balance for informed decisions.

Below is a detailed analysis of each key aspect to support your practical selection.

What are the mainstream types of shot blasting machines and their structural features?

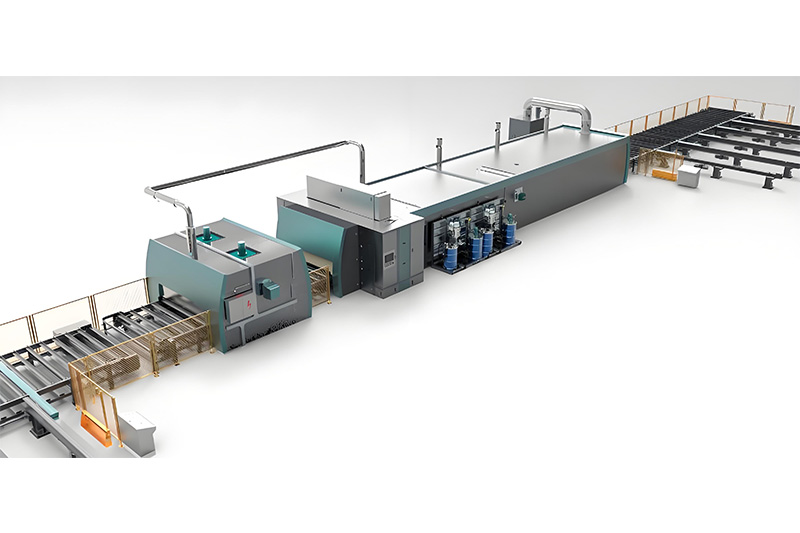

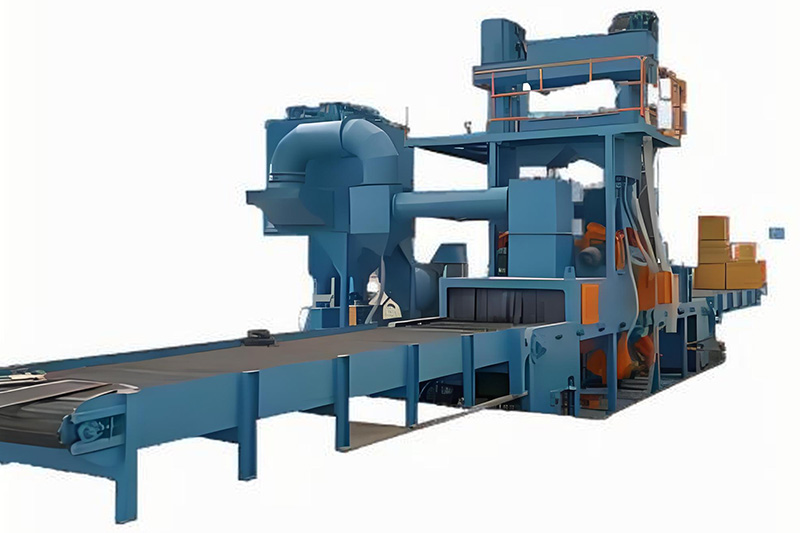

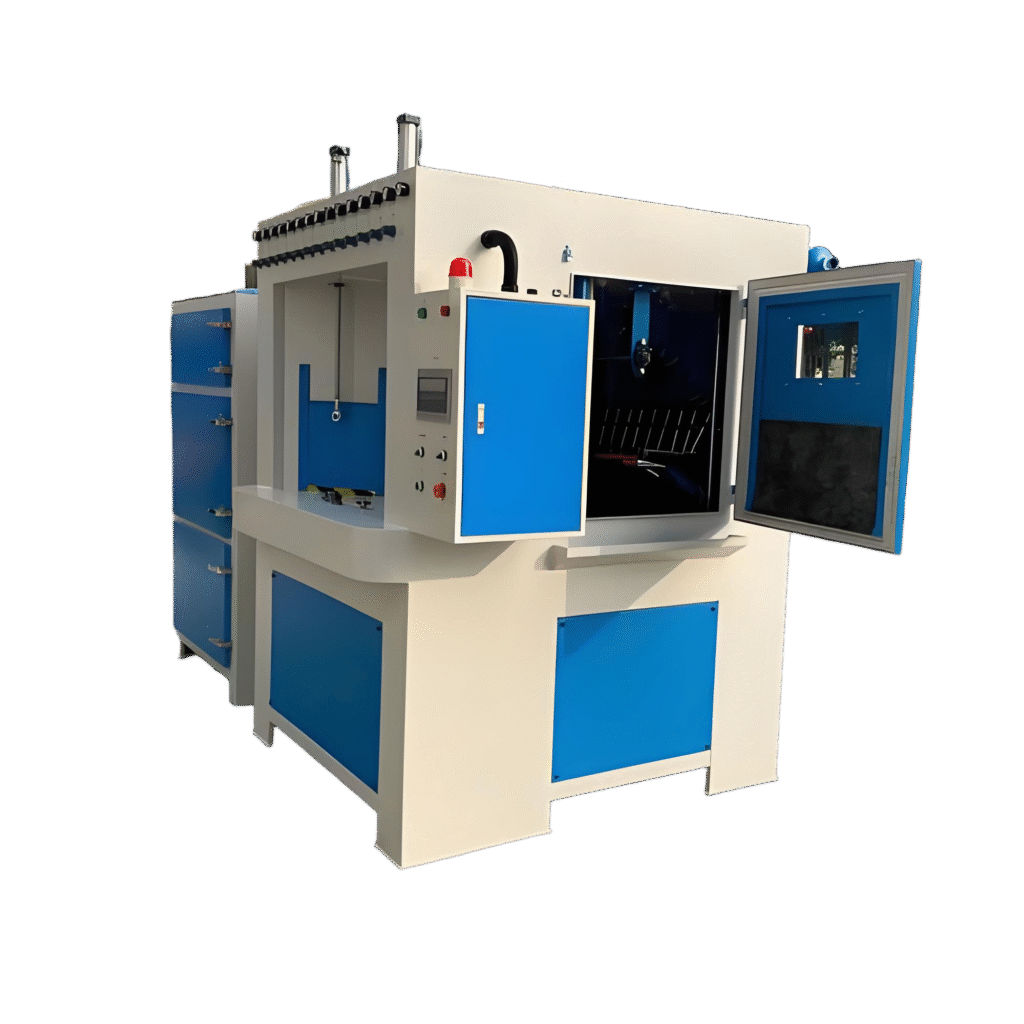

Mainstream shot blasting machines include tumblast, track – type, hook – type, and through – type, each with unique structural features tailored to specific processing needs. Tumblast machines feature a closed cylindrical drum as the core structure. The drum rotates to tumble small workpieces, ensuring every surface makes full contact with abrasive materials. They are equipped with a built – in simple abrasive recycling system, boasting a compact overall design that saves workshop space. Track – type shot blasting machines adopt rubber or steel track conveying structures, which have stronger load – bearing capacity than tumblast machines. The track stably transports medium – sized workpieces, and internal multi – angle shot blasters work together to achieve continuous and efficient processing. Hook – type shot blasting machines are fitted with lifting and rotating hooks. These hooks can suspend large and heavy workpieces and rotate 360 degrees, eliminating dead ends in the shot blasting process. Through – type shot blasting machines are designed with a roller conveyor structure, allowing long workpieces such as plates and profiles to pass through the shot blasting area at a constant speed, making them highly compatible with assembly line operations. These structural designs lay a solid foundation for their respective functional advantages in different application scenarios, which is a key part of Mainstream Models & Structural Features.

How to compare the core performance indicators of different shot blasting machines?

Comparing the core performance indicators of shot blasting machines mainly focuses on shot blasting efficiency, cleaning precision, energy consumption, and durability, which is the core of Core Performance Indicators Comparison. In terms of shot blasting efficiency, track – type shot blasting machines can process 0.2 – 1.5 tons per batch, with a single processing cycle of 3 – 15 minutes, suitable for mass production. Through – type shot blasting machines have the highest efficiency, realizing continuous processing of long workpieces to meet the needs of large – scale production lines. For cleaning precision, hook – type shot blasting machines can precisely control the shot blasting angle and intensity, enabling the surface cleanliness of large workpieces to reach Sa3 level, widely used in high – precision fields like automotive engines. Tumblast machines ensure uniform cleaning of small workpieces through tumbling, but their precision is slightly lower than that of hook – type machines. In terms of energy consumption, tumblast machines have a simple structure and low power, with hourly energy consumption much lower than that of hook – type and through – type machines. Through – type machines, despite high output, have hourly electricity costs ranging from 150 to 300 yuan. Regarding durability, hook – type machines have a robust structure and a long service life, but their hooks and rotating mechanisms require regular lubrication. The tracks of track – type machines are wearing parts, and rubber tracks need periodic replacement to maintain performance.

Which shot blasting machine is suitable for different industrial application scenarios?

Industrial Scenarios Adaptive Selection is crucial for maximizing the effectiveness of shot blasting machines. Tumblast machines are ideal for the hardware and standard parts industry, especially for processing small workpieces such as screws, gears, and stampings. Their closed structure prevents abrasive splashing, making them suitable for small workshops with limited space. Track – type shot blasting machines are widely used in the casting and automotive parts industries, efficiently processing medium – sized castings, forgings, and auto parts like brake discs and crankshafts, balancing efficiency and processing quality. Hook – type shot blasting machines are the first choice in the steel structure and shipbuilding industries, capable of handling large workpieces such as steel beams, engine blocks, and hull segments. The 360 – degree rotating hook ensures thorough cleaning of welding seams and complex structures. Through – type shot blasting machines are mainly applied in the construction steel and plate processing industries, realizing continuous processing of profiles and plates, and integrating perfectly into the assembly line production of prefabricated buildings and steel structure factories. In the precision machinery industry, customized small hook – type shot blasting machines are often used to meet the surface strengthening needs of precision parts.

What key parameters must be considered when selecting a shot blasting machine?

Selecting a shot blasting machine requires a firm grasp of key parameters related to workpiece characteristics, production capacity, and equipment configuration. In terms of workpiece characteristics, size and weight determine the machine model: workpieces over 3 meters long are suitable for through – type machines, while heavy workpieces require hook – type machines with a hook load exceeding 20% of the workpiece weight. Material is also a key factor: high – chromium alloy blade shot blasters are suitable for hard materials like cast iron, while soft materials such as aluminum require machines with adjustable shot speed. For production capacity, small – batch production can choose tumblast machines with a daily output of less than 10 tons, while large – scale production requires track – type or through – type machines with a daily output of over 100 tons. Equipment configuration parameters are equally important: shot blaster power should match processing needs, with small production lines choosing 5.5 – 11kW models and large workshops opting for 15 – 30kW ones. The separation accuracy of the abrasive recycling system should exceed 99% to reduce equipment wear, and the indoor lining should use 8 – 12mm wear – resistant manganese steel plates to extend service life.

What common misunderstandings and pitfalls should be avoided in shot blasting machine selection?

Avoiding common misunderstandings and pitfalls in shot blasting machine selection is essential to reduce long – term operational costs. One major pitfall is blindly pursuing low prices while ignoring quality. Some low – cost machines use inferior materials, resulting in frequent replacement of wearing parts and increased maintenance costs. Another pitfall is neglecting environmental compliance; equipment without efficient dust removal systems will have excessive dust concentration, leading to regulatory penalties. Ignoring site constraints is also a mistake: hook – type machines require workshops at least 5 meters high, and forced installation in low spaces will hinder operation. Additionally, overestimating production capacity leads to equipment idleness, while underestimating it causes production bottlenecks. Ignoring after – sales service is another common error; manufacturers lacking sound after – sales support will result in prolonged production downtime when equipment malfunctions.

How to balance cost, maintenance, and environmental compliance in selection?

Balancing cost, maintenance, and environmental compliance is a key consideration for enterprises during selection. In terms of cost, it is necessary to conduct a comprehensive cost – benefit analysis, not just focusing on the initial purchase price but also considering long – term costs such as energy consumption, abrasive replacement, and maintenance. Choosing energy – efficient models can reduce daily operating costs, and selecting machines with universal wearing parts can lower maintenance costs. For maintenance, prioritize manufacturers with a sound after – sales service system and sufficient spare parts supply to ensure timely maintenance and minimize downtime. Environmental compliance cannot be ignored. Select machines equipped with high – efficiency dust removal and noise reduction devices to meet national environmental protection standards and avoid fines and production suspension risks. Enterprises can also choose energy – saving and environmentally friendly models that qualify for relevant policy subsidies, achieving a win – win situation of economic and environmental benefits.

Conclusion

This guide helps you select the right shot blasting machine with comprehensive professional insights.