- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

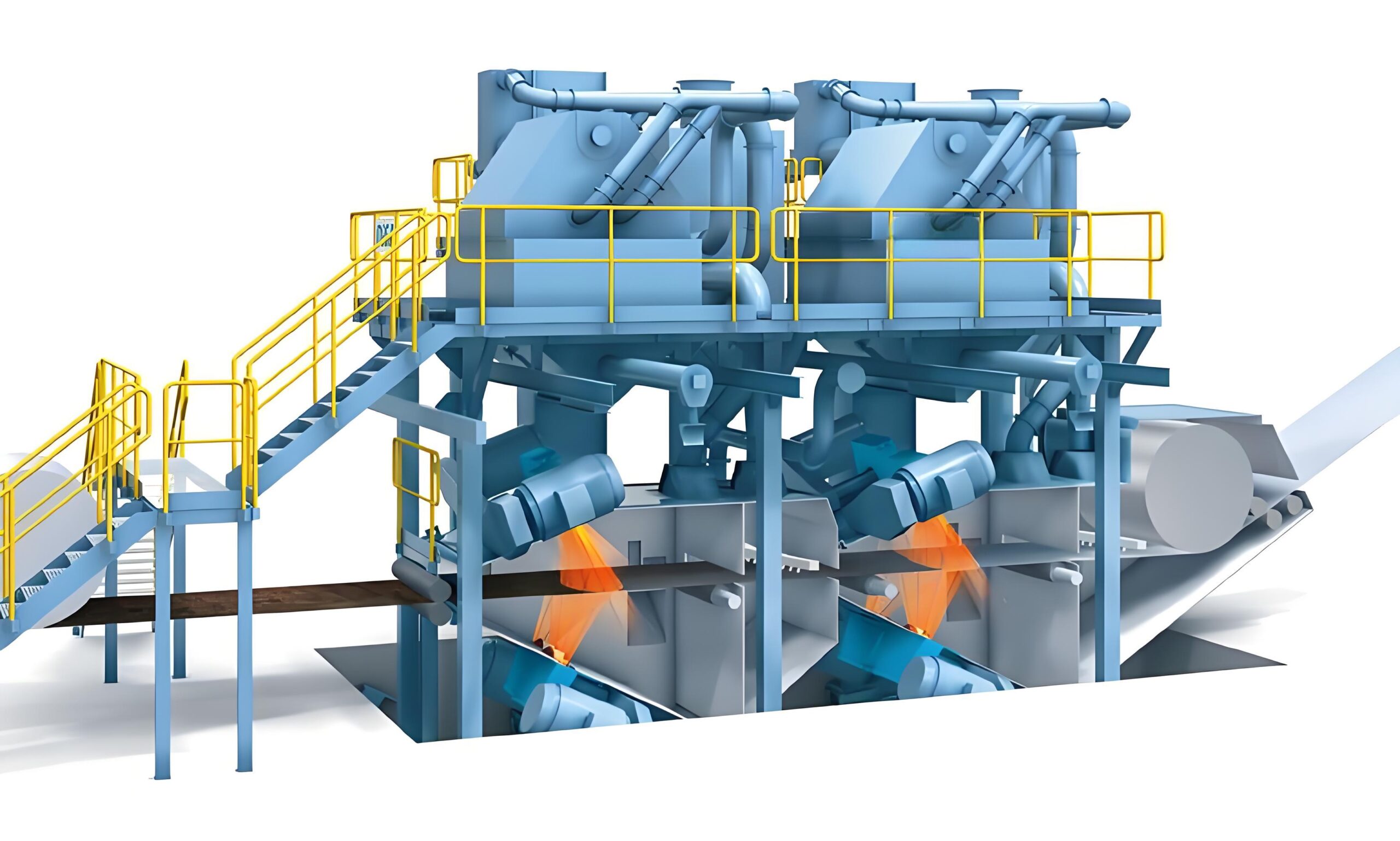

Steel strip descaling machine

Steel strip descaling machine

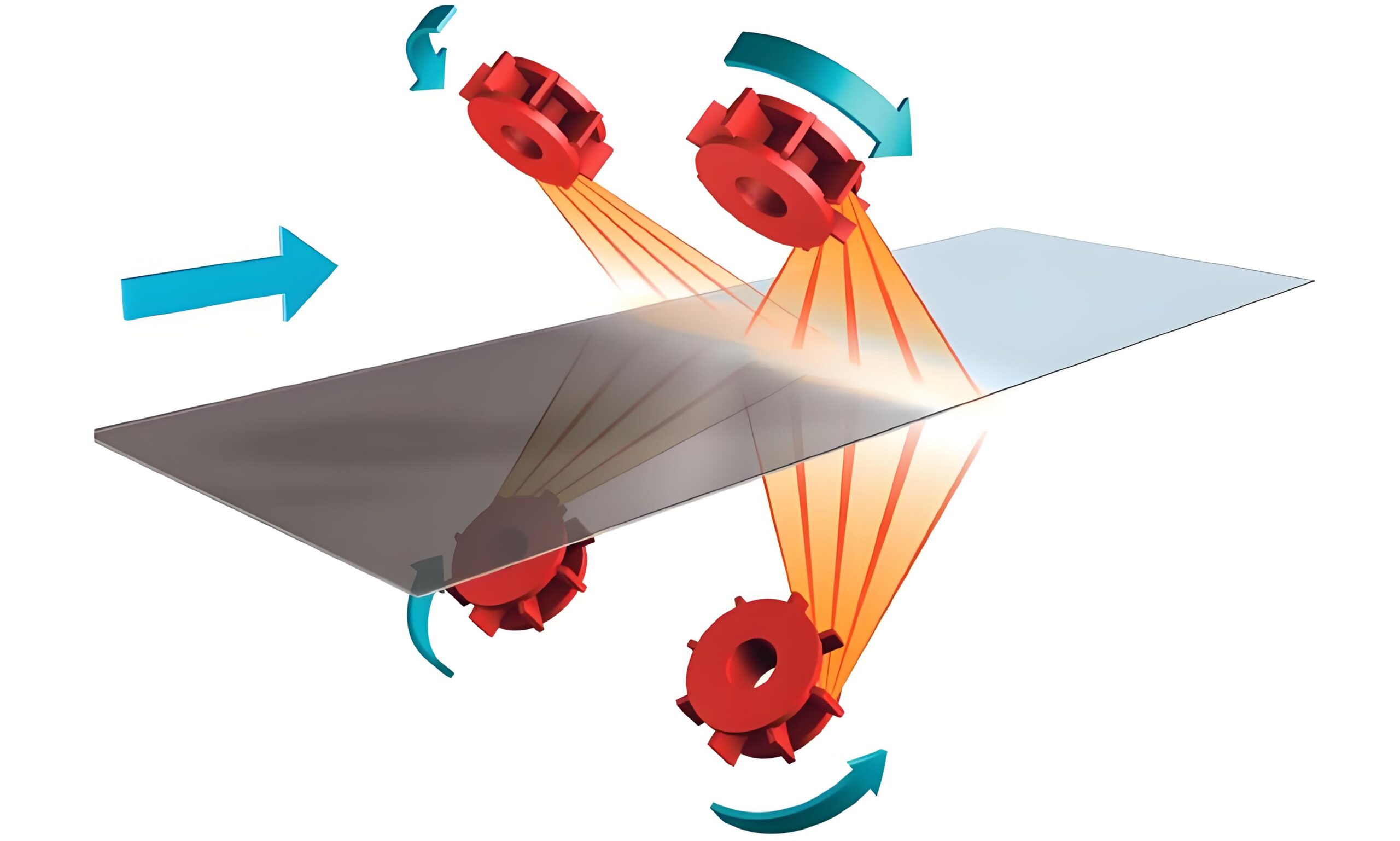

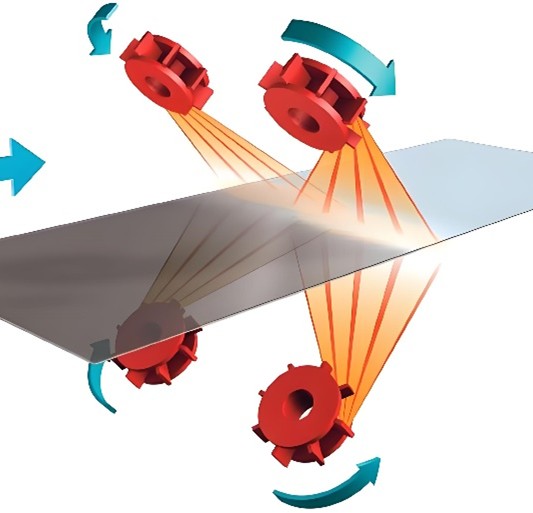

- Blast wheel arrangement and concept ensures maximum exploitation of blasting energy and intensity and prevents from blasting interferences

- Efficient abrasive blow-off, maximum abrasive cleaning and recovery, efficient dust collection

- High wear-resistant execution of parts subject to wear

- Continuous further development ensures application of latest technology

Quote Now

Product Parameters

Applications

- High performance mechanical descaling of steel strip (stainless and silicon steel, low carbon, titanium) integrated in highly sophisticated continuous production lines

- Type series ranging up to strip widths of 600 mm / 1650 mm / 2100 mm

- Modular concept meeting production requirements

Main Benefits

- Blast wheel arrangement and concept ensures maximum exploitation of blasting energy and intensity and prevents from blasting interferences

- Efficient abrasive blow-off, maximum abrasive cleaning and recovery, efficient dust collection

- High wear-resistant execution of parts subject to wear

- Continuous further development ensures application of latest technology

Feature

Blasting cabinet

- Highly wear resistant manganese liner plate

- Long lifetime up to 15000 hours

3D simulation

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Motor power up to 90 kw

- High chrome wear resistant parts

Multi blasting station

- Multi blasting station for high speed processing