- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

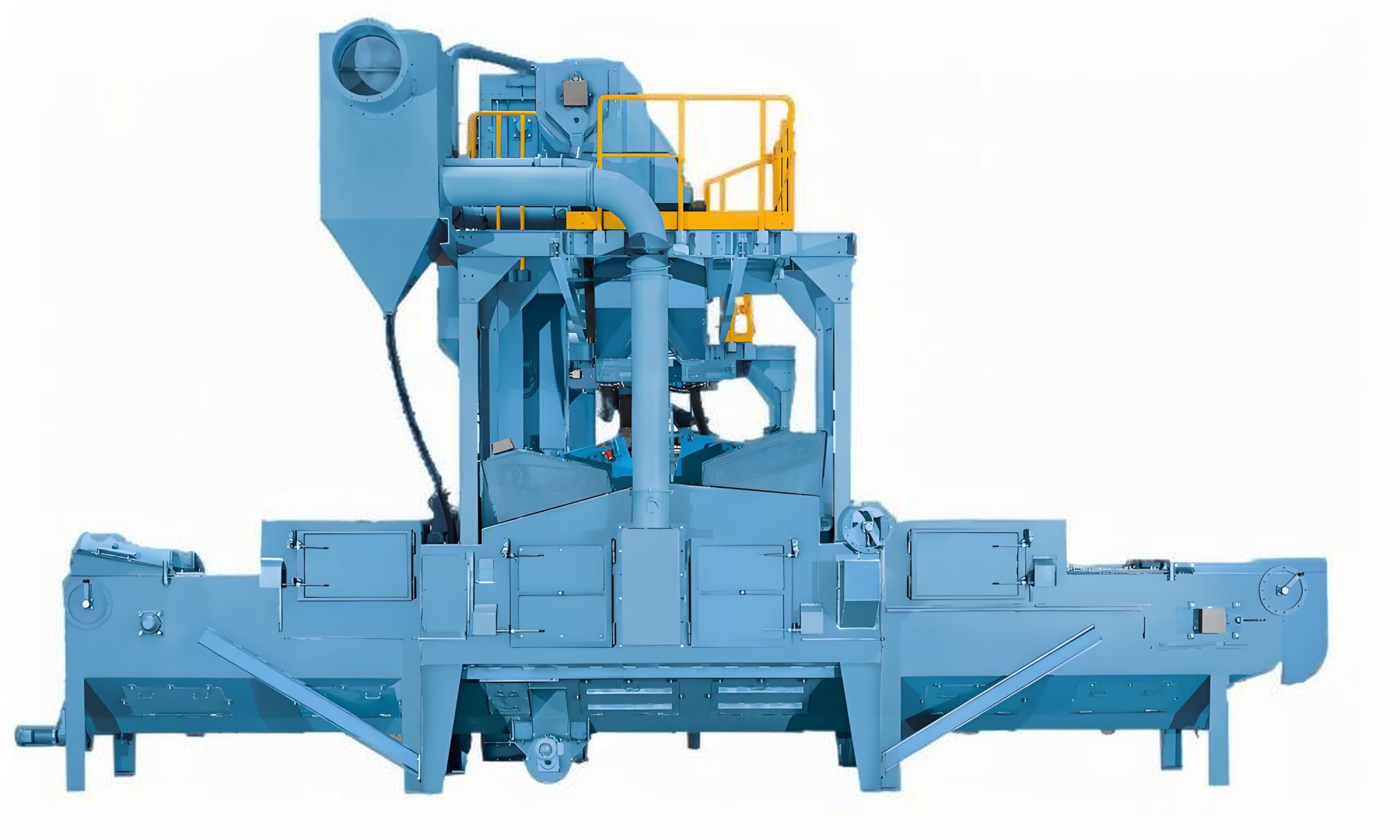

Spring peening machine

Spring peening machine

- Lower production costs due to automatic operation, high output and uniform quality

- High specific blast performance: parts are always shot peened in the hot spot of the blast stream where the effect is best

- High energy efficiency, high economy: blast wheels fully exploit the energy applied and transform it to blast effect

- Continuous throughfeed operation is simple, safe and ideally suited for fully automatic production

- No intermediate stocking of workpieces, parts tracking is possible

Product Parameters

Applications

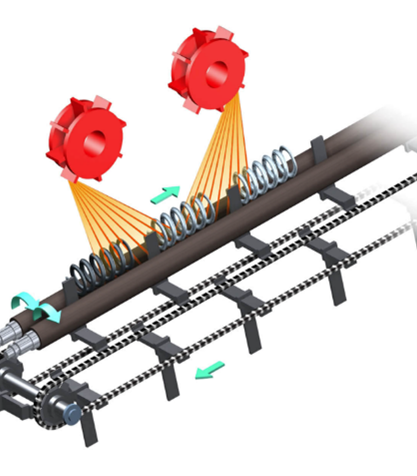

Shot peening is a well-established process that ensures greater strength of the material and extends its service life. Springs, which are used in rail or automotive industry are constantly exposed to torsion and compressive loading, which causes material fatigue and consequently springs breakage.

Shot peening is mainly used for parts from the aviation and space industry as well as the automotive industry. For example, these include springs, drive shafts, crankshafts, gear wheels, connecting rods, steering and gear parts, turbine blades etc. By carrying out this process, the component weight can be reduced whereas the mechanical strength remains the same. Among other things, this leads to weight advantages which cause savings on fuel consumption.

Main Benefits

- Lower production costs due to automatic operation, high output and uniform quality

- High specific blast performance: parts are always shot peened in the hot spot of the blast stream where the effect is best

- High energy efficiency, high economy: blast wheels fully exploit the energy applied and transform it to blast effect

- Continuous throughfeed operation is simple, safe and ideally suited for fully automatic production

- No intermediate stocking of workpieces, parts tracking is possible

Model & Specification

| Type | SP-2 | SP-4 |

| Exterior diameter of workpieces (mm) | 80-250 | 80-250 |

| Workpiece length max. (mm) | 600 | 600 |

| Number of blast wheels | 2 | 4 |

| Power per blast wheel (kW) | 45 | 45 |

| Blast wheel speed max. (rpm) | 2600 | 2600 |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

- The part is conveyed through the blast machine on a specially designed roll type material handling system.

- An extensive range of high production blast cabinets are available to handle a wide variety of work sizes at variable cleaning speeds.

- 3D simulation for wheel arrangement

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

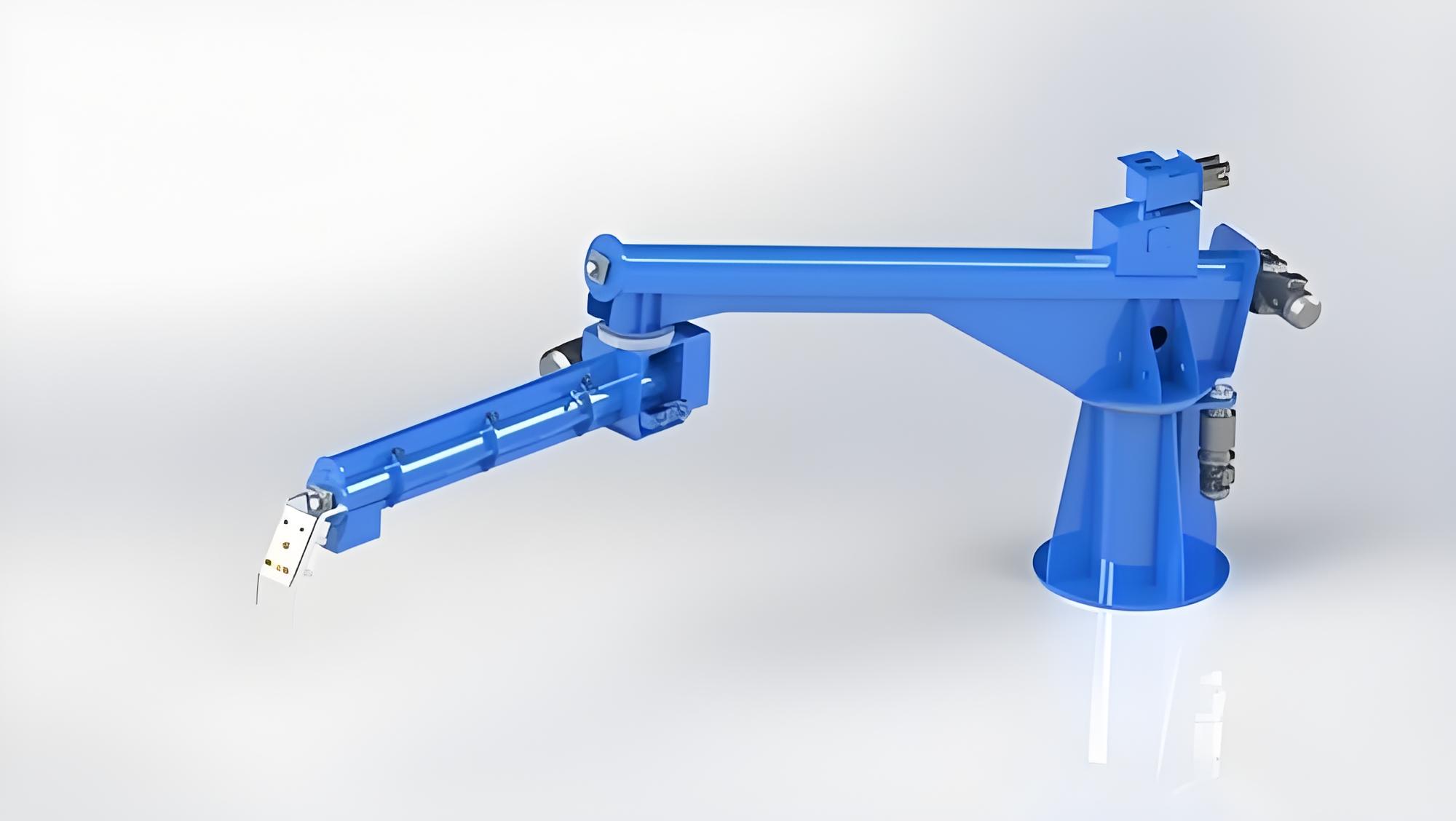

- To combine with automatic production line, the automatic loading device is available.