- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

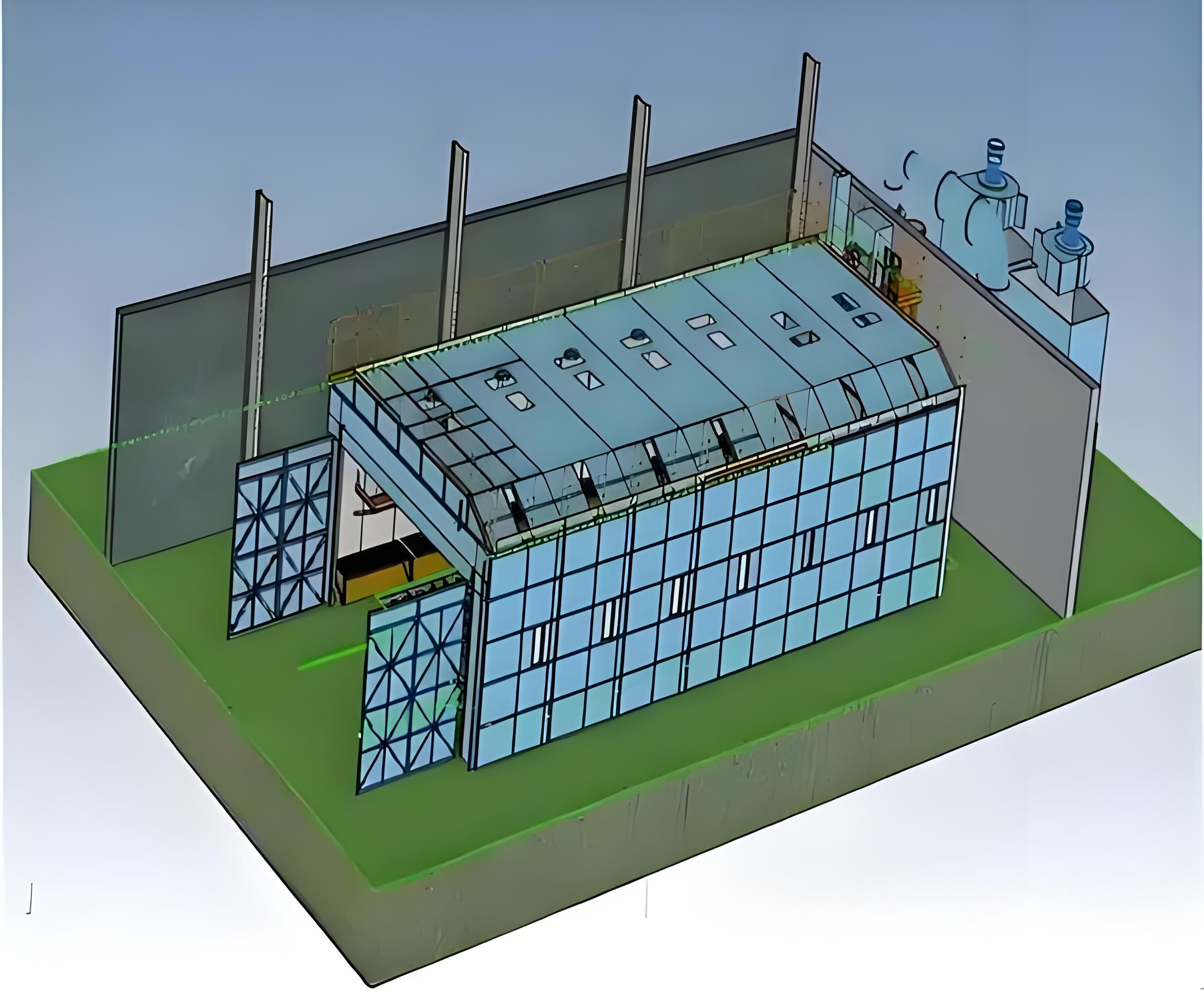

Shell sand thermal baking reclamation

Shell sand thermal baking reclamation

Reduced Waste:

Thermal reclamation significantly reduces the amount of spent foundry sand that needs to be disposed of, promoting a more sustainable approach.

Cost Savings:

By reusing sand, foundries can reduce their reliance on new sand purchases, leading to cost savings.

Improved Sand Quality:

Thermal reclamation can restore sand to near-original quality, ensuring consistent performance in casting processes

Environmental Benefits:

Reduced waste and the potential for using reclaimed sand in other applications contribute to a smaller environmental footprint.

Product Parameters

Applications

- Sand Preparation:

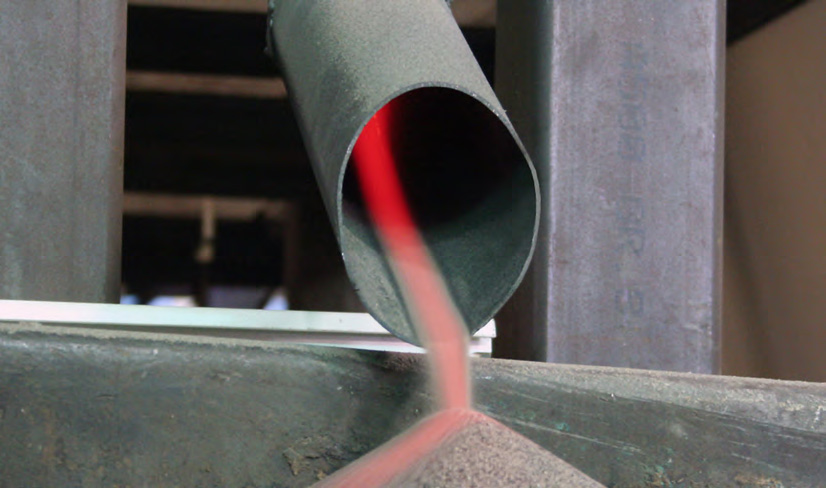

Used foundry sand, often after mechanical reclamation, is fed into a thermal reclamation unit.

- Heating:

The sand is heated to high temperatures (typically 1,200 to 1,500°F or 650 to 815°C). This can be done using various methods, such as a rotary retort or a fluidized bed furnace.

- Binder Removal:

The heat causes organic binders and other contaminants to burn off or vaporize, leaving behind clean sand grains.

- Cooling and Collection:

The reclaimed sand is cooled and collected for reuse.

Main Benefits

Reduced Waste:

Thermal reclamation significantly reduces the amount of spent foundry sand that needs to be disposed of, promoting a more sustainable approach.

Cost Savings:

By reusing sand, foundries can reduce their reliance on new sand purchases, leading to cost savings.

Improved Sand Quality:

Thermal reclamation can restore sand to near-original quality, ensuring consistent performance in casting processes

Environmental Benefits:

Reduced waste and the potential for using reclaimed sand in other applications contribute to a smaller environmental footprint.

The green sand preparation line processing ability from 10T/hr to 200 T/hr, contact our engineer for proposal and design.