- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

Sand coated iron mold casting

Sand coated iron mold casting

- Superior Surface Finish

- High Dimensional Accuracy

- Ability to Cast Complex Geometries

- Reduced Machining Requirements

Quote Now

Product Parameters

Applications

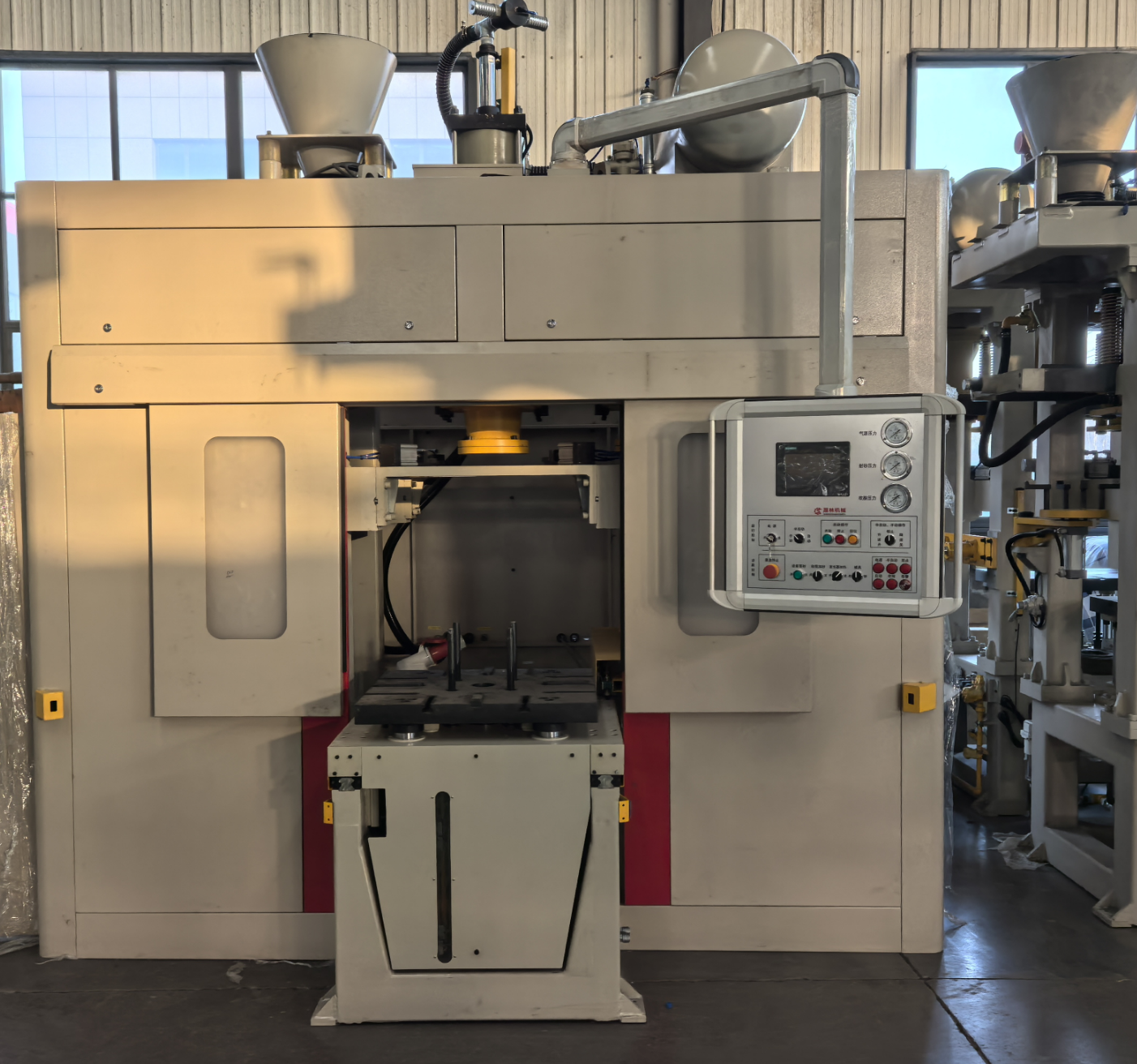

Iron mold sand-coated casting is a casting process in which a thin layer of sand is covered on the inner cavity of a metal mold (called an iron mold) to form a mold. Because the sand coating layer is relatively thin (4~8mm), it is economically reasonable to use more expensive high-quality modeling materials. As a result, the quality of the castings is greatly improved and the waste is significantly reduced; due to the rigidity of the iron sand-coated casting mold Very good, thereby significantly improving the dimensional accuracy and compactness of the casting.

Main Benefits

- Superior Surface Finish

- High Dimensional Accuracy

- Ability to Cast Complex Geometries

- Reduced Machining Requirements

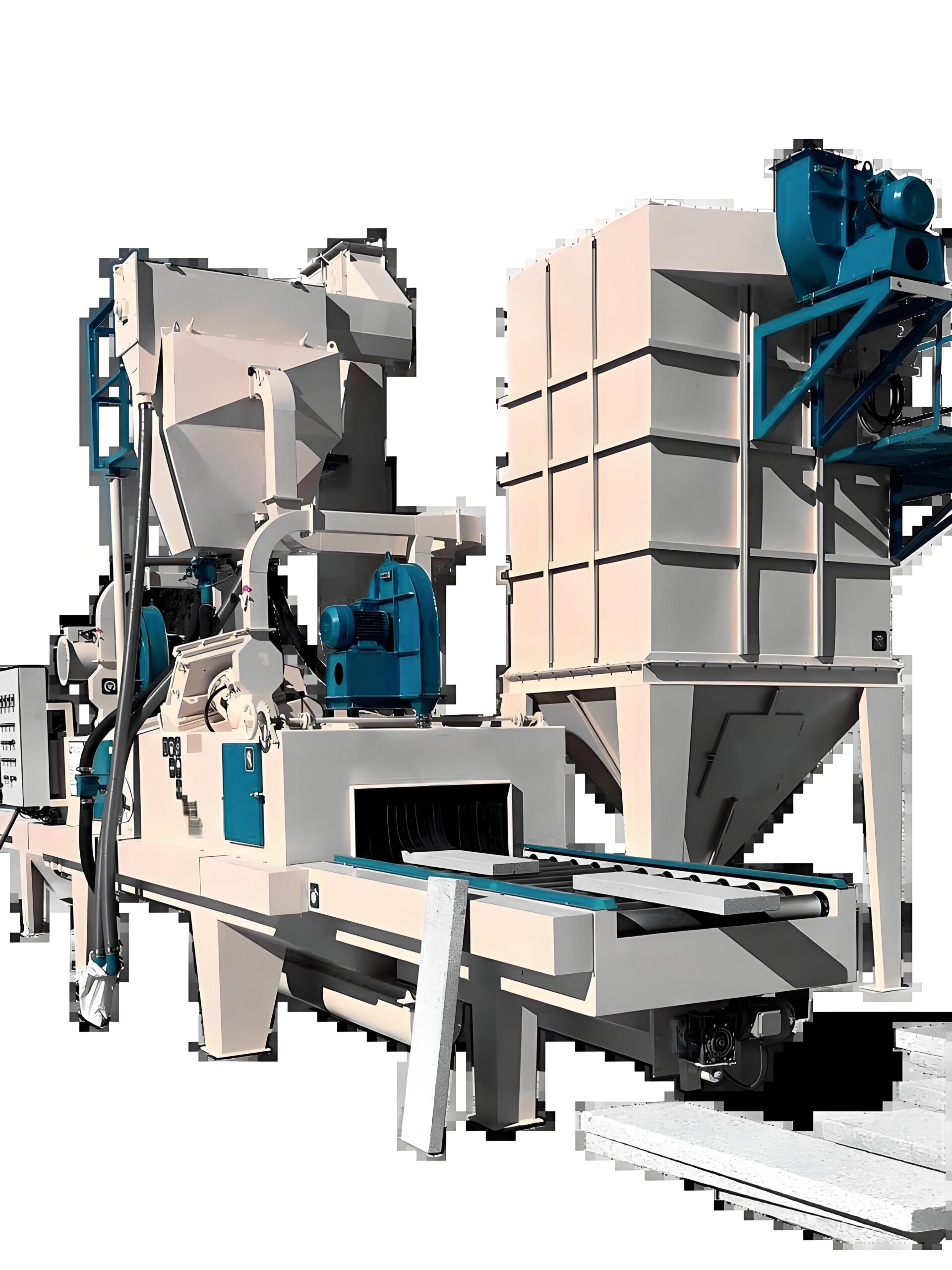

We make tailor made and turnkey project for sand coated iron mold casting line, you can contact and get the design for your particular needs.