- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

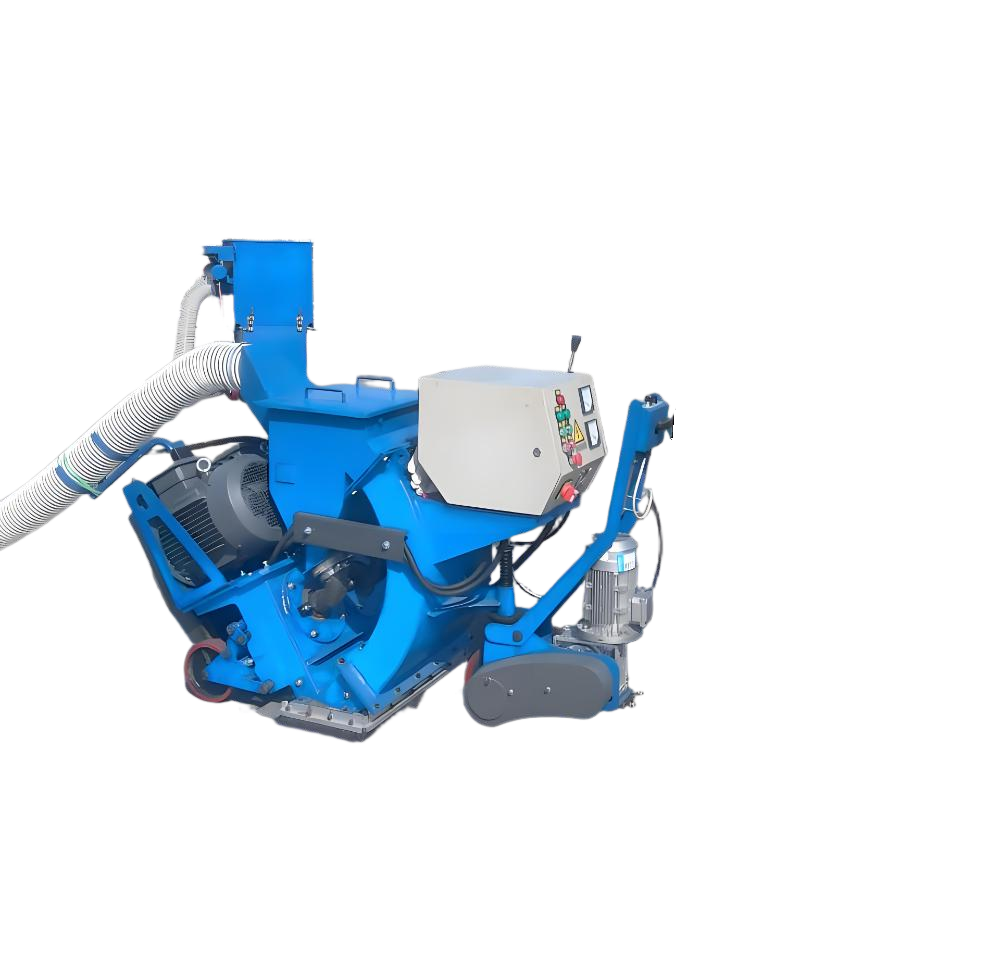

Rotary drum blast machine

Rotary drum blast machine

- No foundations required

- Minimum floor space required

- Consistent and highly efficient

- educed maintenance vs tumble blast

- 100% manganese process drum with an increased working life

- Drum oscillates while processing, reducing cycle time over conventional drum styles

Quote Now

Product Parameters

Applications

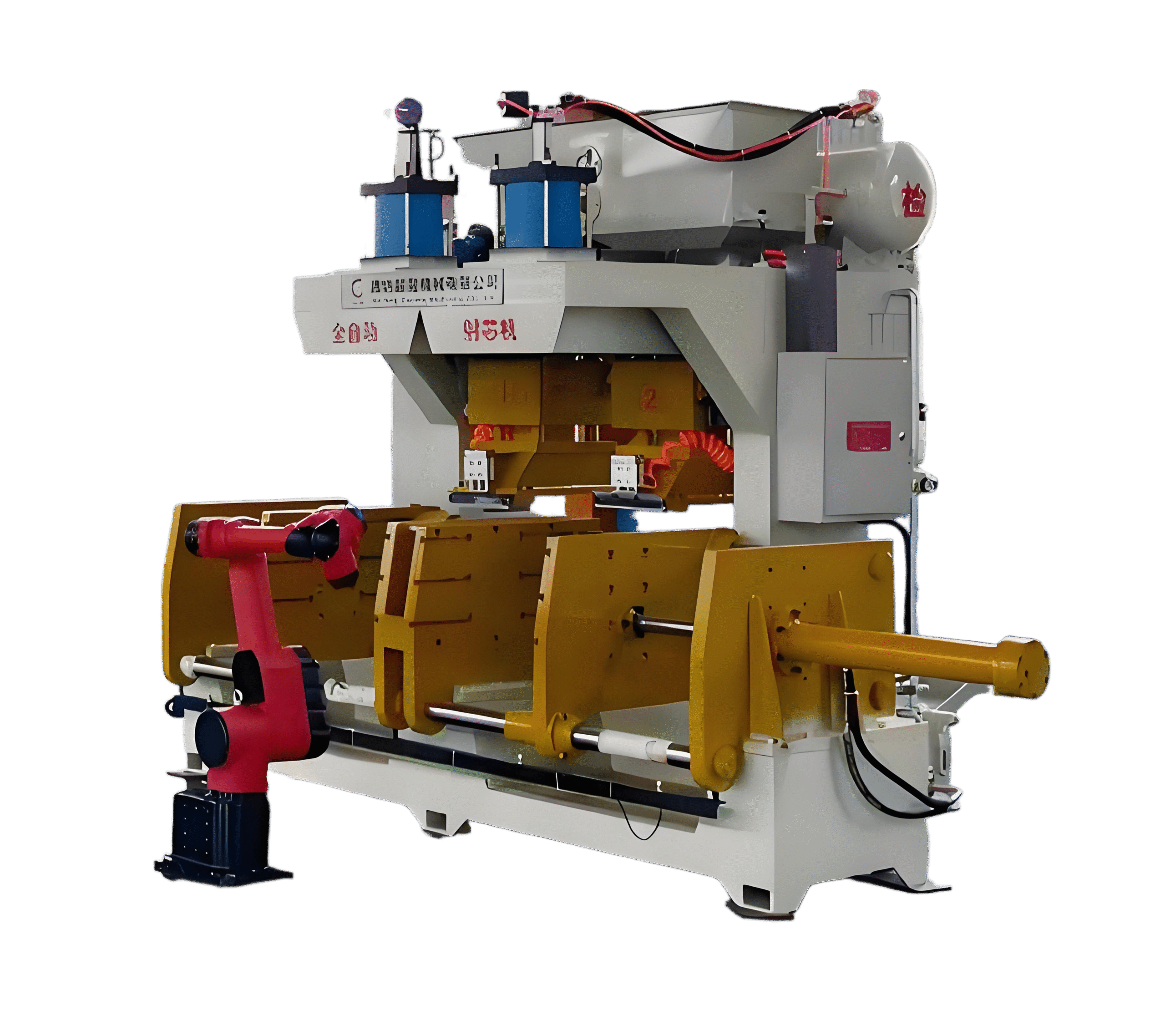

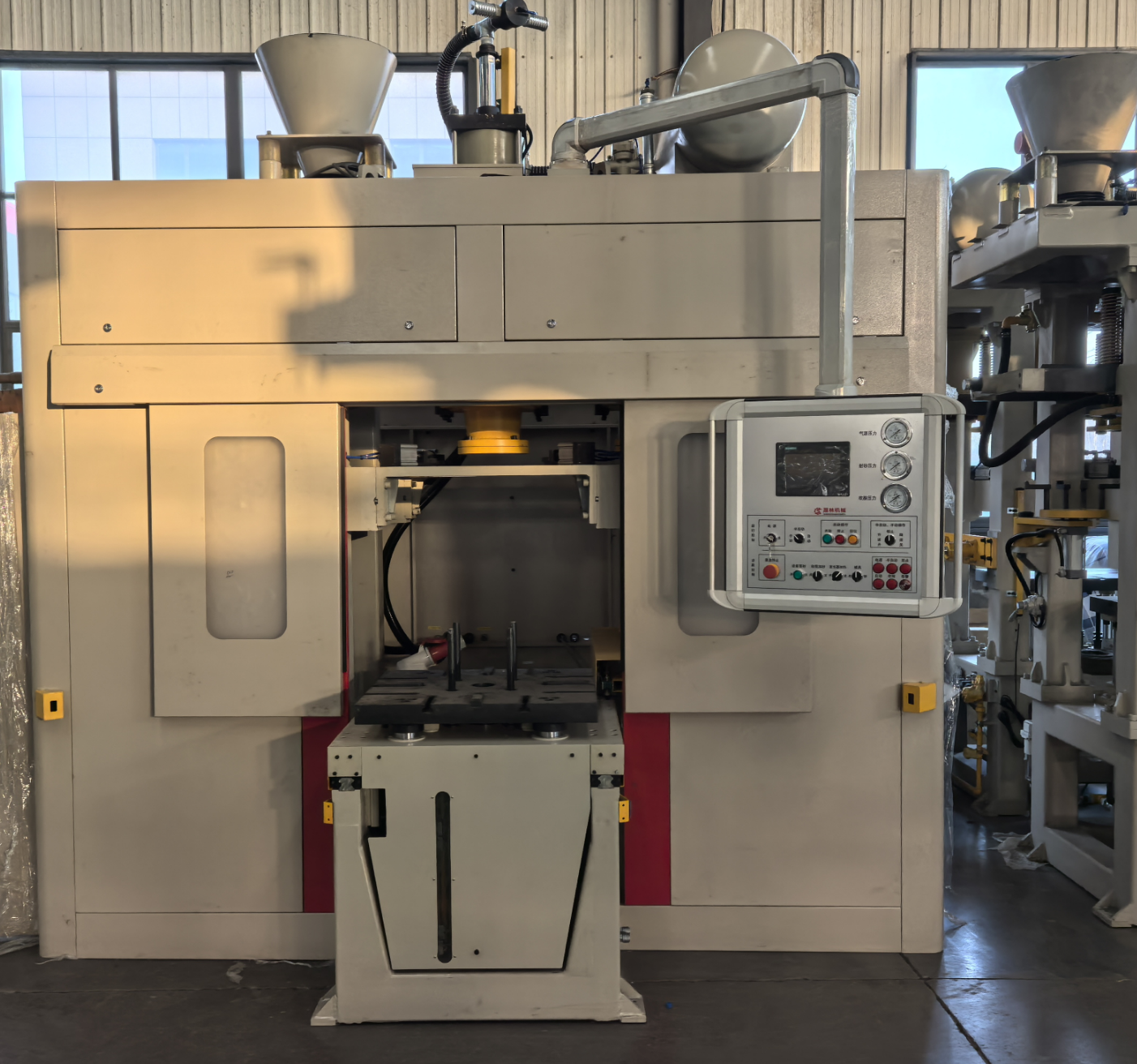

Shot blasting machine with rotating barrel is suitable for cleaning smaller castings, forgings, parts after heat treatment and machine parts in repair workshops.

This type of machine is ideal for processing bulk materials. Compared to the widely used troughed belt principle, there are important advantages: as the drum is made from a single piece, transitions from moving to fixed machine parts are avoided. This prevents parts from becoming jammed. In addition, drums are easier to empty completely, which prevents individual workpieces from being processed twice.

Main Benefits

- No foundations required

- Minimum floor space required

- Consistent and highly efficient

- educed maintenance vs tumble blast

- 100% manganese process drum with an increased working life

- Drum oscillates while processing, reducing cycle time over conventional drum styles

Model & Specification

| Technical data | RD150 | RD300 | RD500 | GT15 |

| Drum volume (l) | 150 | 300 | 500 | 1500 |

| High performance turbine (quantity) | 1 | 1 | 1 | 1 |

| High-performance turbine (kW) | up to 15 | up to 22 | up to 22 | Up to 30 |

| abrasive conveyance | screw | screw | screw | Screw |

| max. room diagonal of the workpieces (mm) | 400 | 450 | 450 | 450 |

| Cartridge filter unit (standard) | PF 4-06 | PF 4-09 | PF 4-12 | PF4-24 |

| Volume capacity of the cartridge filter system (m3/h) | 2000 | 2600 | 4500 | 7500 |

If these standard models don’t fit your needs, we can design tailor-made shot blasting machine according to your workpieces.

Feature

Manganese drum

- 100% manganese drum

High speed blast wheel

- Direct motor driven/belt driven

- High speed abrasive throw

- Eco motor optional

- High chrome wear resistant parts

Skip loader

- Bulk skip loader for mass production