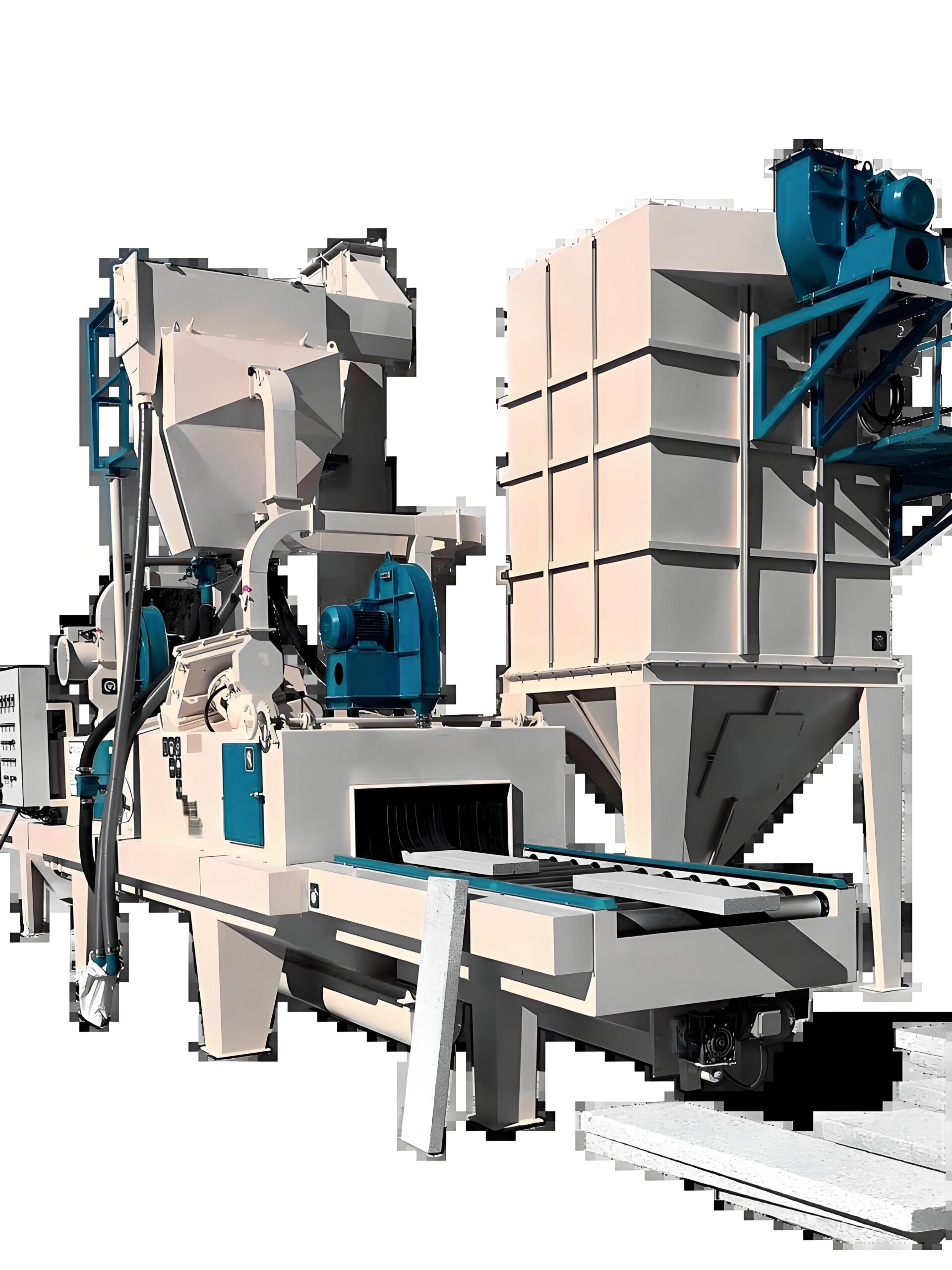

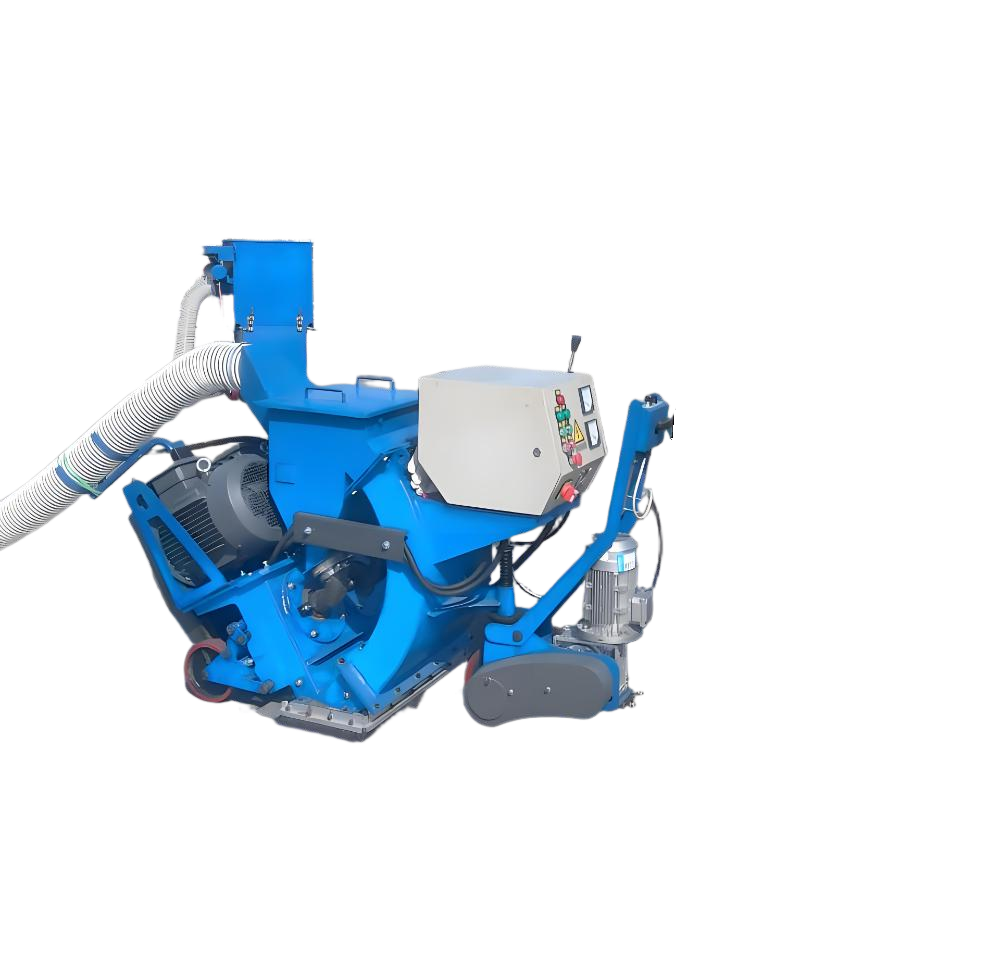

- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

No bake sand Molding

No bake sand Molding

- Superior Surface Finish: Furan resin molds produce a smoother surface finish compared to traditional sand casting, reducing the need for post-casting finishing work.

- High Dimensional Accuracy: Furan sand casting offers excellent dimensional accuracy, making it ideal for parts that need to fit tightly or require complex features.

- Faster Curing and Turnaround: The furan resin mold cures quickly, reducing the overall lead time of production compared to clay-based sand casting.

- Strength and Durability: The furan resin binder enhances the strength of the mold, allowing it to withstand the high pressures of molten metal pouring and maintain structural integrity.

- Versatility: This method can be used for a wide variety of metals, including ferrous and non-ferrous alloys, making it suitable for diverse industries.

- Reduced Shrinkage: Furan sand casting is known for low shrinkage rates, ensuring better quality and more reliable castings.

Product Parameters

Applications

Furan resin sand casting is a no-bake sand mold process, which furan resin plays a role as a bonding agent. This molding technique maintains pretty excellently in casting good quality and smooth surface finish. Whereas, some limitations are high cost and high raw material requirements.

Furan sand casting with good surface finish, high dimensional standard steel castings which widely used in the sand casting foundries. This type of sand casting is suitable for manufacturing from 200kg casting to 20-ton casting, 30ton casting, max weight 80ton casting per pc.

Sand mold with high strength, good formability, low gas generation, etc advantage, can reduce steel casting defects in the furan resin sand casting and moulding process, suitable on heavy castings, small casting, and complex casting.

Main Benefits

- Superior Surface Finish: Furan resin molds produce a smoother surface finish compared to traditional sand casting, reducing the need for post-casting finishing work.

- High Dimensional Accuracy: Furan sand casting offers excellent dimensional accuracy, making it ideal for parts that need to fit tightly or require complex features.

- Faster Curing and Turnaround: The furan resin mold cures quickly, reducing the overall lead time of production compared to clay-based sand casting.

- Strength and Durability: The furan resin binder enhances the strength of the mold, allowing it to withstand the high pressures of molten metal pouring and maintain structural integrity.

- Versatility: This method can be used for a wide variety of metals, including ferrous and non-ferrous alloys, making it suitable for diverse industries.

- Reduced Shrinkage: Furan sand casting is known for low shrinkage rates, ensuring better quality and more reliable castings.

We make tailor made and turnkey project for furan resin no bake sand molding, you can contact and get the design for your particular needs.