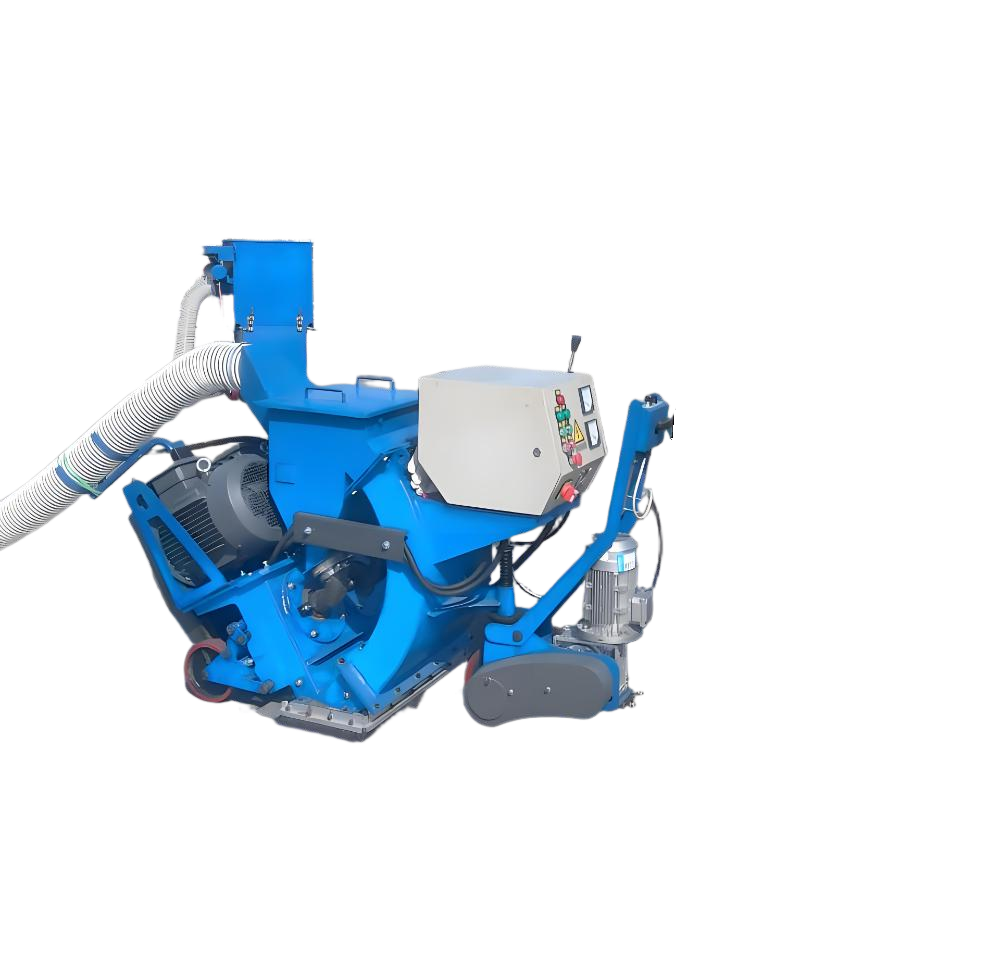

- High Efficiency – Quick and thorough cleaning.

- Durable Construction – Robust materials for longevity.

- Customizable Solutions – Tailored to specific needs.

- Energy-Saving Technology – Reduces costs, lessens environmental impact.

- Expert After-Sales Support – Comprehensive service and technical assistance.

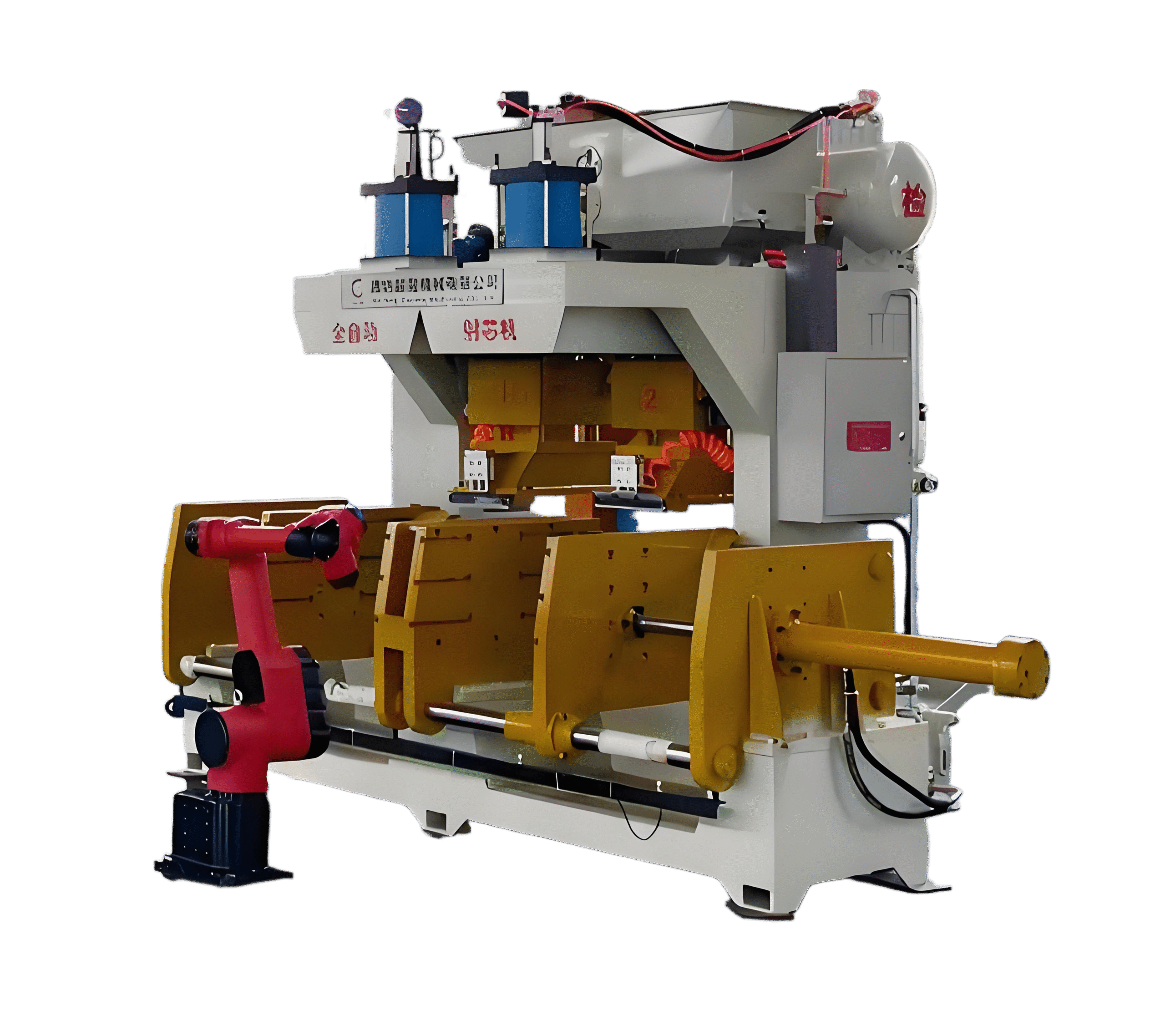

Hot box core making machine

Hot box core making machine

- Faster Production than CO₂/Silicate: Significantly faster curing (seconds/minutes vs. minutes/hours for drying-based processes) enables higher throughput compared to CO₂ or air-set processes.

- Good Core Strength & Hardness: Produces cores with substantially higher green strength than CO₂ silicate cores, reducing breakage during handling and molding. Suitable for cores needing moderate structural integrity.

- Good Surface Finish: Generally produces better casting surface finishes than CO₂ silicate cores.

Quote Now

Product Parameters

Applications

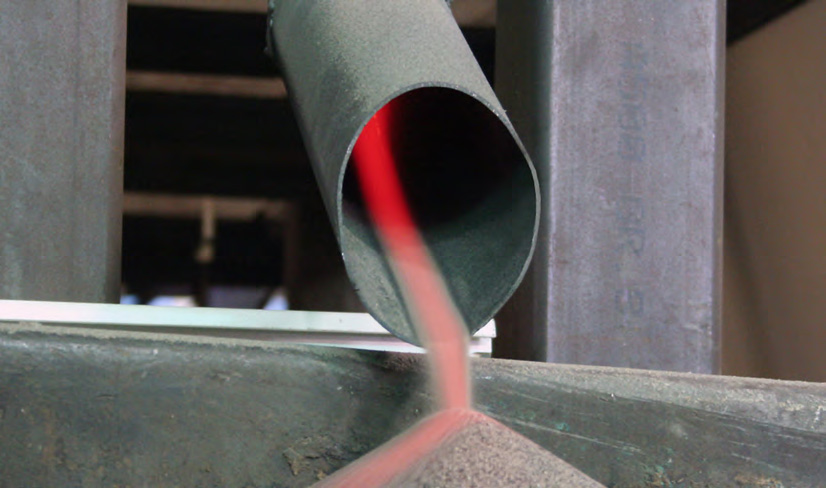

A Hot Box Core Making Machine is an automated foundry machine designed to produce sand cores by thermally curing a sand-resin mixture inside a heated core box. It’s a core production method falling between the simpler CO₂/silicate process and the more advanced (but faster/cooler) Cold Box process in terms of complexity, speed, and performance.

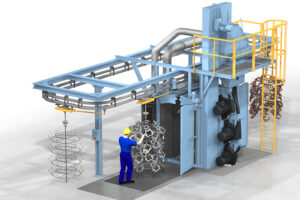

Hot Box machines are suited for medium-to-high volume production of cores requiring good strength, reasonable detail, and faster production than CO₂, but where the investment or complexity of Cold Box isn’t justified. Common applications include:

- Automotive: Brake drums, suspension components, simpler engine parts (like oil pans, covers), differential carriers, pump housings.

- Industrial Valves & Fittings: Valve bodies, pipe fittings, flanges.

- General Machinery: Gear blanks, housings, brackets, pulleys.

- Agricultural Equipment: Transmission cases, housing components.

- HVAC: Compressor housings.

- Electric Motors: End shields, frames.

Main Benefits

- Faster Production than CO₂/Silicate: Significantly faster curing (seconds/minutes vs. minutes/hours for drying-based processes) enables higher throughput compared to CO₂ or air-set processes.

- Good Core Strength & Hardness: Produces cores with substantially higher green strength than CO₂ silicate cores, reducing breakage during handling and molding. Suitable for cores needing moderate structural integrity.

- Good Surface Finish: Generally produces better casting surface finishes than CO₂ silicate cores.

- Good Dimensional Accuracy: Capable of producing reasonably complex cores with adequate dimensional accuracy for many applications.

- Improved Shakeout vs. CO₂: While not as easy-shake as modern Cold Box binders, Hot Box cores generally collapse better than hardened CO₂ silicate cores after casting.

- Lower Initial Investment than Cold Box: Equipment (machine and core boxes) is generally less expensive than equivalent Cold Box systems, as it doesn’t require complex gas handling, scrubbing, or sealed systems.

- Simpler Chemistry than Cold Box: Uses liquid resins only (no separate gas catalyst system required). Easier binder supply logistics.

- Lower Binder Cost than Cold Box: UF/PF resins are generally less expensive per unit than the two-part binders plus amine gases used in Cold Box.

- Established Technology: Well-understood process with readily available materials and expertise.

- Energy Efficient Heating: Modern machines use efficient electric cartridge heaters or thermal oil systems within the core boxes, minimizing wasted heat.

We make tailor made and turnkey project for core making system, you can contact and get the design for your particular needs.