Wrong Sand Blast Rooms selection causes inefficiency and quality issues; this guide ensures proper Blast Room Equipment matching.

This guide details key factors and steps for selecting Sand Blast Rooms, helping you choose suitable Blast Room Equipment based on your production needs and budget.

Explore core selection factors and practical tips for Sand Blast Rooms below.

How to Determine the Size and Type of Sand Blast Rooms Based on Workpiece Requirements?

The size and type of Sand Blast Rooms are determined by the size, quantity, and shape of workpieces, which is the primary step in selection.

- Confirm the maximum workpiece dimensions: measure the length, width, and height of the largest workpiece to be processed, and select Sand Blast Rooms with an internal space 30-50% larger than the workpiece to ensure sufficient operation space for operators and Blast Room Equipment. For small workpieces (such as hardware accessories), compact Sand Blast Rooms (3m×3m×3m) are suitable; for large workpieces (such as steel structures, automotive chassis), choose large-scale Sand Blast Rooms (6m×8m×5m or larger).

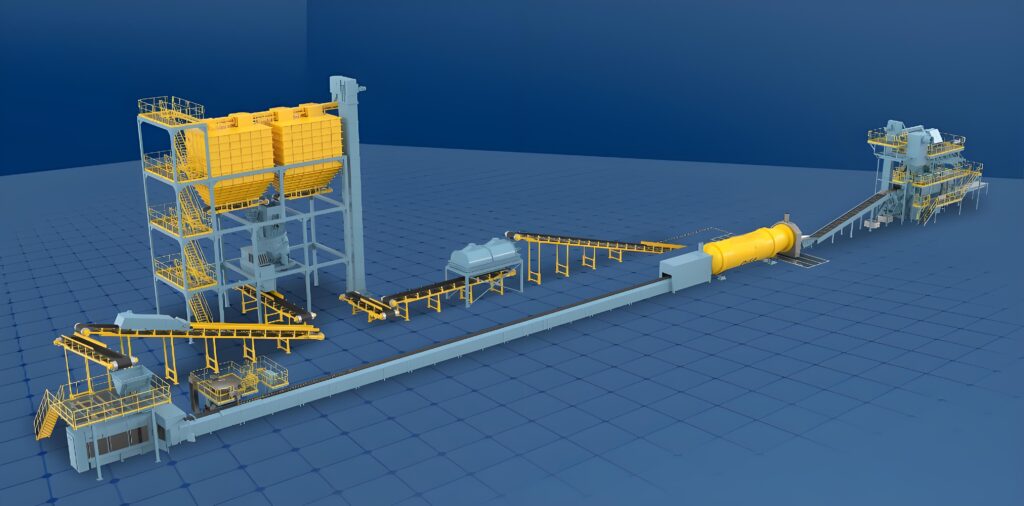

- Select the type based on production mode: for batch production, choose continuous Sand Blast Rooms equipped with conveyor belts to improve efficiency; for small-batch, irregular workpieces, manual or semi-automatic Sand Blast Rooms are more flexible.

- Consider the workpiece weight: if processing heavy workpieces, ensure Sand Blast Rooms are equipped with load-bearing platforms or overhead cranes as part of the Blast Room Equipment to facilitate workpiece handling.

How to Select Matching Blast Room Equipment for Sand Blast Rooms?

Blast Room Equipment is the core of Sand Blast Rooms, and selecting matching equipment ensures stable and efficient operation.

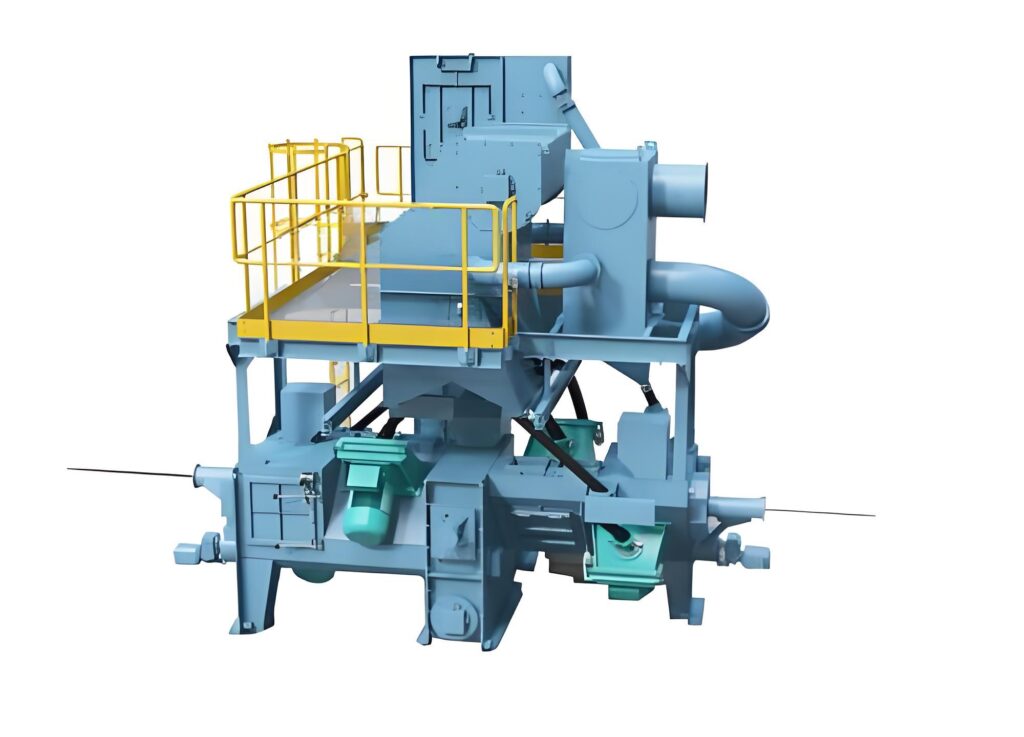

- Choose the right sand blasting machine: for Sand Blast Rooms, pressure-type or suction-type sand blasting machines are commonly used. Pressure-type machines are suitable for high-intensity cleaning (such as heavy rust removal), while suction-type machines are ideal for precision workpieces. Ensure the machine’s power and abrasive flow rate match the Sand Blast Rooms size—large rooms require high-power machines to ensure uniform shot blasting.

- Select auxiliary Blast Room Equipment: equip with efficient dust removal systems to keep the operation environment clean and meet environmental standards; install abrasive recovery systems to recycle usable abrasives, reducing costs; add lighting and ventilation equipment to improve operation safety and comfort.

- Pay attention to equipment compatibility: ensure all Blast Room Equipment (sand blasting machine, dust remover, recovery system) is compatible with each other and the Sand Blast Rooms size to avoid operational faults.

What Other Key Factors Should Be Considered When Selecting Sand Blast Rooms?

In addition to size, type, and Blast Room Equipment, several other factors affect the selection of Sand Blast Rooms and their long-term use.

- Consider the production budget: balance equipment quality and cost, choose cost-effective Sand Blast Rooms and Blast Room Equipment—avoid excessive pursuit of high configuration leading to waste, or choosing low-quality products leading to frequent maintenance.

- Focus on environmental and safety standards: select Sand Blast Rooms with good sealing performance to prevent abrasive leakage and dust pollution; ensure Blast Room Equipment is equipped with safety protection devices (such as emergency stop buttons, protective shields) to protect operators.

- Consider after-sales service: choose manufacturers that provide perfect after-sales service, including equipment installation, debugging, maintenance, and spare parts supply, to avoid troubles in subsequent use.

- Consider future expansion needs: select Sand Blast Rooms and Blast Room Equipment with expandable functions to adapt to future changes in production scale or workpiece types.

Conclusion

Consider workpiece needs, Blast Room Equipment and budget to select suitable Sand Blast Rooms.

For professional advice on Sand Blast Rooms selection and Blast Room Equipment matching,

contact us via email:[email protected]