Burrs and rust on hardware affect quality; a sand blast machine solves these issues efficiently and thoroughly.

This guide details how to use a sand blasting machine to deburr and derust hardware workpieces, ensuring smooth surfaces and long-term durability.

Explore practical steps and tips for hardware deburring and derusting with a sand blast machine below.

How to Use a Sand Blasting Machine for Hardware Workpiece Deburring?

Deburring hardware workpieces with a sand blasting machine requires precise operation to ensure smooth surfaces without damaging the workpiece.

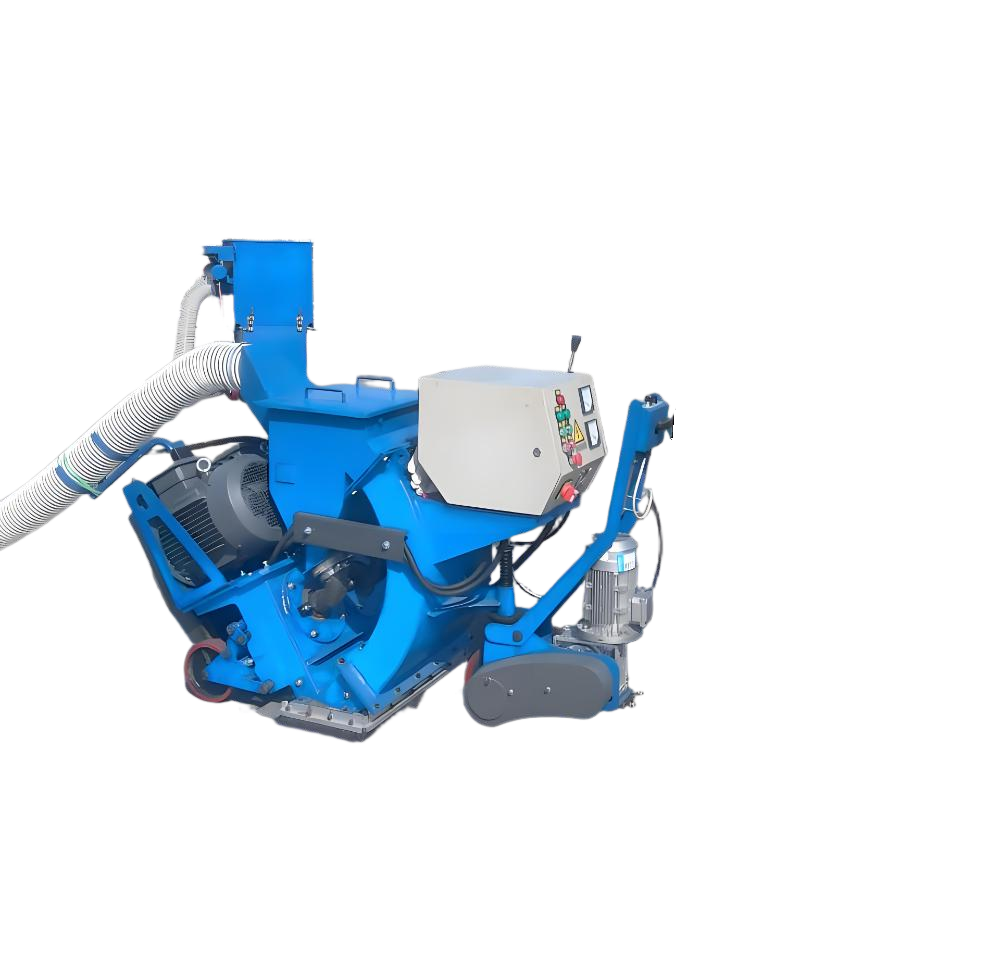

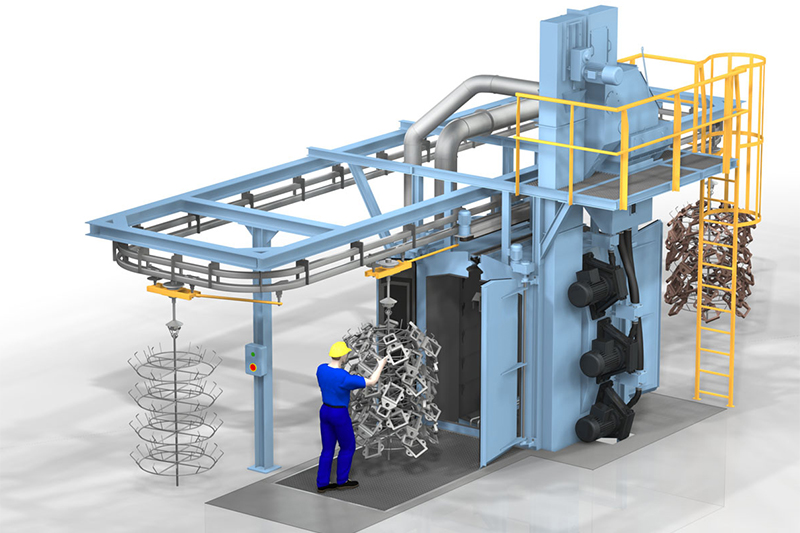

- Select the appropriate sand blast machine and abrasive: for small hardware (such as screws, nuts), use a portable sand blasting machine; for large batches, choose an automatic sand blast machine. Opt for fine-grained abrasives (0.3-0.8mm), such as glass beads or aluminum oxide, which can remove burrs gently without leaving scratches.

- Adjust the machine parameters: set the air pressure to 0.4-0.6MPa and the abrasive flow rate to 150-200kg/min, avoiding excessive pressure that may deform thin hardware. Keep the nozzle 30-50mm from the workpiece and move it evenly at a speed of 5-10cm/s to ensure uniform deburring. Third, post-deburring treatment: use compressed air to blow off residual abrasives on the workpiece surface, ensuring no debris remains. Proper operation of the sand blasting machine can remove burrs thoroughly, improving the precision and appearance of hardware workpieces.

How to Use a Sand Blasting Machine for Hardware Workpiece Derusting?

Derusting hardware workpieces with a sand blasting machine is efficient and environmentally friendly, suitable for various rust levels.

- Pre-treat the hardware: remove surface oil stains with a degreasing agent, as oil will affect the derusting effect and adhesion of abrasives. Dry the workpiece completely before putting it into the sand blast machine.

- Select the right abrasive and machine parameters: for light rust, use fine steel shot; for heavy rust, choose angular steel grit (0.8-1.5mm) to enhance derusting intensity. Adjust the air pressure to 0.6-0.8MPa and the flow rate to 200-250kg/min, ensuring the abrasive can penetrate rust layers effectively. For complex-shaped hardware, adjust the nozzle angle or use a rotating fixture to ensure all rusted surfaces are covered.

- Control derusting time: 30-60 seconds per workpiece is generally sufficient; over-derusting may damage the base material. After derusting, the workpiece surface will be clean and have a certain roughness, which is conducive to subsequent painting or electroplating. Using a sand blasting machine for derusting is more efficient than manual or chemical methods, and it can extend the service life of hardware workpieces.

What Are the Key Precautions for Sand Blasting Deburring and Derusting of Hardware?

Mastering key precautions ensures safe and effective operation of the sand blasting machine and high-quality hardware processing.

- Operator protection: wear professional protective equipment, including goggles, dust masks, and protective clothing, to avoid injury from abrasive splashing and dust inhalation.

- Machine maintenance: before each use, check the sand blast machine’s pipeline, nozzle, and air compressor for leaks or blockages; after use, clean the machine thoroughly to remove residual abrasives and debris, which can extend the service life of the sand blasting machine.

- Workpiece placement: place hardware workpieces evenly in the machine, avoiding overlapping or shielding, to ensure uniform deburring and derusting.

- Abrasive management: use clean, uniform-sized abrasives, and filter out impurities regularly to avoid clogging the sand blast machine and affecting processing effect. Fifth, parameter adjustment: adjust the machine parameters according to the hardware material and size, and conduct a test run on a waste workpiece before formal processing to ensure optimal results. These precautions can reduce faults and improve the efficiency of deburring and derusting operations.

Conclusion

A sand blasting machine achieves efficient, high-quality deburring and derusting of hardware workpieces.

For professional advice on sand blast machine selection and hardware processing,

contact us via email: [email protected]