Single surface treatment has flaws; combining Wheelblast Equipment with sandblasting/pickling avoids quality risks and ensures optimal results.

This guide details combined application scenarios, operation points of Wheelblast Equipment with sandblasting/pickling, helping improve surface treatment efficiency and quality.

Explore below to master key schemes of Wheelblast Equipment and sandblasting combined applications.

What Are the Scenarios and Operation Points of Wheelblast Equipment Combined with Sandblasting?

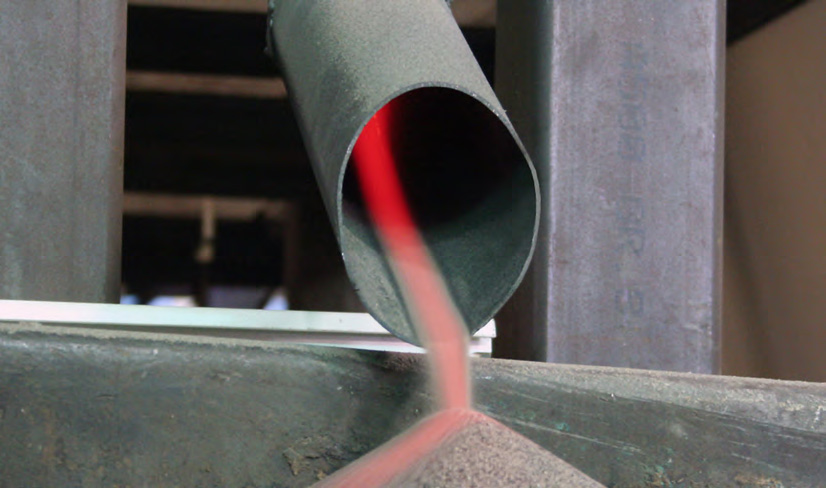

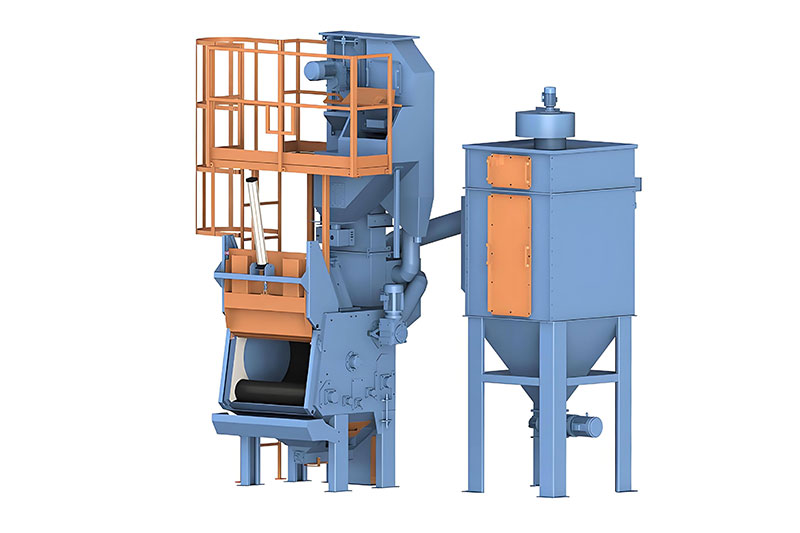

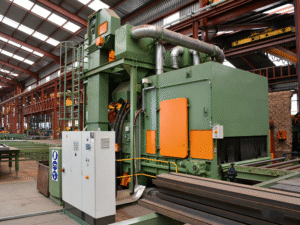

Combining Wheelblast Equipment with sandblasting integrates the high-efficiency of wheel blast and the precision of sandblasting, making it ideal for complex workpieces that require both large-area cleaning and fine finishing. Typical scenarios include large steel structures (bridges, ship hulls), precision mechanical parts, and automotive components. For large steel structures, Wheelblast Equipment is first used for high-speed shot projection to quickly remove thick oxide skin, rust, and welding slag—this step completes 80% of the cleaning work efficiently. Then, sandblasting is applied to local dead angles (welding seams, bolt holes) and areas requiring high surface finish, using fine abrasives to achieve uniform roughness. Operation points: strictly follow the sequence of Wheelblast Equipment first, then sandblasting, to prevent fine sandblasting abrasives from being embedded in the workpiece surface during wheel blast. Adjust Wheelblast Equipment parameters (abrasive size 1.0-1.2mm, shot flow rate 40-50 kg/min) for rough cleaning, and use small-nozzle sandblasting equipment (abrasive size 0.3-0.5mm) for fine processing. Ensure the interval between the two processes does not exceed 2 hours to avoid re-oxidation. This combination improves efficiency by 30-40% compared to single sandblasting and enhances surface treatment quality significantly.

What Are the Scenarios and Operation Points of Wheelblast Equipment Combined with Pickling?

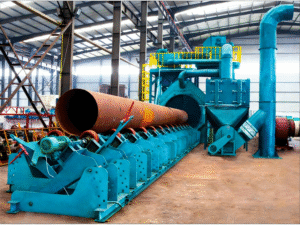

Wheelblast Equipment combined with pickling is widely used for workpieces requiring high-purity surfaces, such as stainless steel components, high-strength steel castings, and aerospace parts. Pickling can thoroughly remove stubborn oxide scale and impurities that Wheelblast Equipment alone cannot eliminate, while Wheelblast Equipment pre-treatment breaks dense oxide layers to speed up pickling. Application scenarios include stainless steel pipe production, high-pressure boiler components, and precision forgings. For stainless steel pipes, Wheelblast Equipment first performs shot blasting to create micro-cracks on the surface oxide scale, allowing pickling solution to penetrate quickly. Then, the workpiece is immersed in a mixed acid solution (hydrochloric acid + nitric acid) for pickling. Operation points: control Wheelblast Equipment’s shot intensity (Almen intensity 0.2-0.3A) to avoid damaging the base material. After wheel blast, clean the surface with high-pressure water to remove residual abrasives before pickling—this prevents abrasives from reacting with acid and affecting pickling effect. Strictly control pickling temperature (40-60℃) and time (5-15 minutes) to avoid over-pickling. Post-pickling, neutralize and passivate immediately. This combination reduces pickling time by 50% and ensures surface purity, avoiding defects from incomplete oxide removal. Notably, sandblasting is sometimes used as a supplementary process here for local fine cleaning after pickling.

What Are the Core Advantages of Combining Wheelblast Equipment with Sandblasting/Pickling?

Combining Wheelblast Equipment with sandblasting/pickling has obvious advantages over single processes, meeting modern industrial strict requirements. First, improved quality: Wheelblast Equipment handles large-area rough cleaning, sandblasting achieves fine finishing, and pickling removes residual impurities—multi-stage treatment ensures high cleanliness and uniform roughness. Second, enhanced efficiency: Wheelblast Equipment’s high speed reduces subsequent process workload, and its pre-treatment shortens sandblasting and pickling time. For example, processing large steel structures with Wheelblast Equipment + sandblasting is 30% more efficient than single sandblasting. Third, cost reduction: the combination reduces sandblasting abrasive consumption by 25% and pickling acid solution usage by 30%, lowering rework costs from incomplete treatment. Fourth, expanded application scope: it can handle complex-shaped workpieces, thick oxide scale parts, and high-precision requirements that single processes struggle with. Additionally, the combined process improves the adhesion of subsequent coating/plating, extending workpiece service life. These advantages make Wheelblast Equipment + sandblasting/pickling a mainstream choice in high-end manufacturing.

What Precautions Should Be Taken When Combining Wheelblast Equipment with Sandblasting/Pickling?

To ensure the effect and safety of combining Wheelblast Equipment with sandblasting/pickling, key precautions must be followed. First, process sequence: For Wheelblast Equipment + sandblasting, always use wheel blast first to avoid sandblasting abrasives being embedded during wheel blast. For Wheelblast Equipment + pickling, wheel blast pre-treatment is mandatory to ensure acid penetration. Second, inter-process cleaning: After Wheelblast Equipment operation, clean the surface with high-pressure air/water to remove residual abrasives and dust, preventing re-contamination in sandblasting/pickling. Third, equipment matching: Select Wheelblast Equipment and sandblasting equipment that match workpiece size and treatment requirements—for small precision parts, use small-sized Wheelblast Equipment with fine-nozzle sandblasting. Fourth, environmental safety: Equip Wheelblast Equipment with a dust removal system to avoid dust pollution; sandblasting should also be conducted in enclosed chambers. Pickling requires a corrosion-resistant workshop, and operators must wear protective gear. Fifth, quality inspection: Inspect surface cleanliness and roughness after each process (Wheelblast Equipment, sandblasting, pickling) to ensure compliance. Following these precautions avoids process failures and quality risks, ensuring stable operation.

Conclusion

Combining Wheelblast Equipment with sandblasting/pickling optimizes surface treatment quality and efficiency.